In order to expand our injection molding machine's market worlwide, we would like to welcome agents all over the world to come and discuss business with us.

Our requirements to exclusive agent as below;

1.Good sales and after service team;

2.With full experience in injection molding machine industry, can promise a certain yearly sales amount.

What we will support is to give the most competitive price to all our agents.

Our company has established over 10 years, now is a leading company that professional on making and developing small injection molding machines.

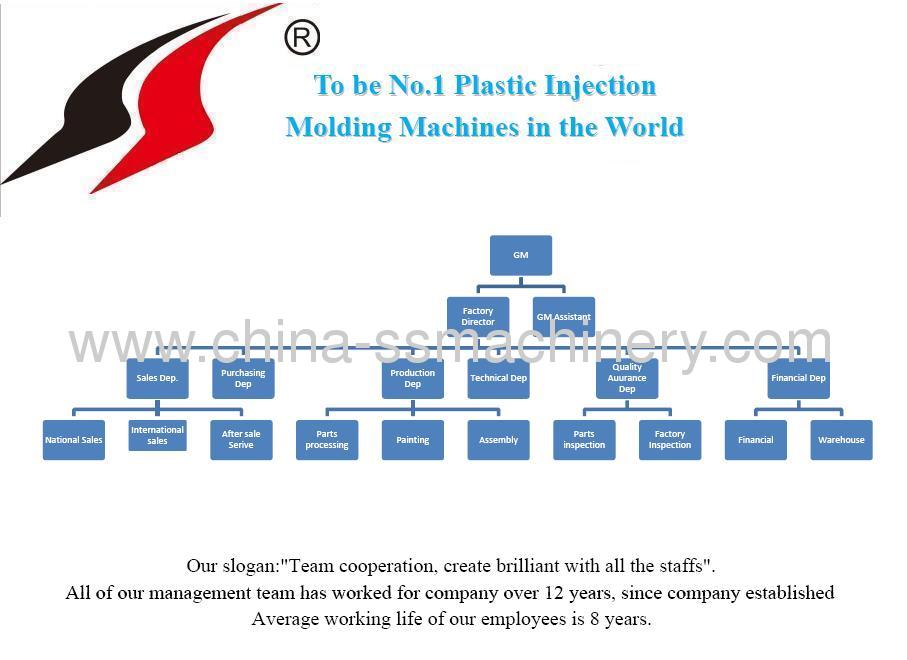

Our slogan is team cooperation, create brilliant with all our staffs and partners.

Welcome your consulting.

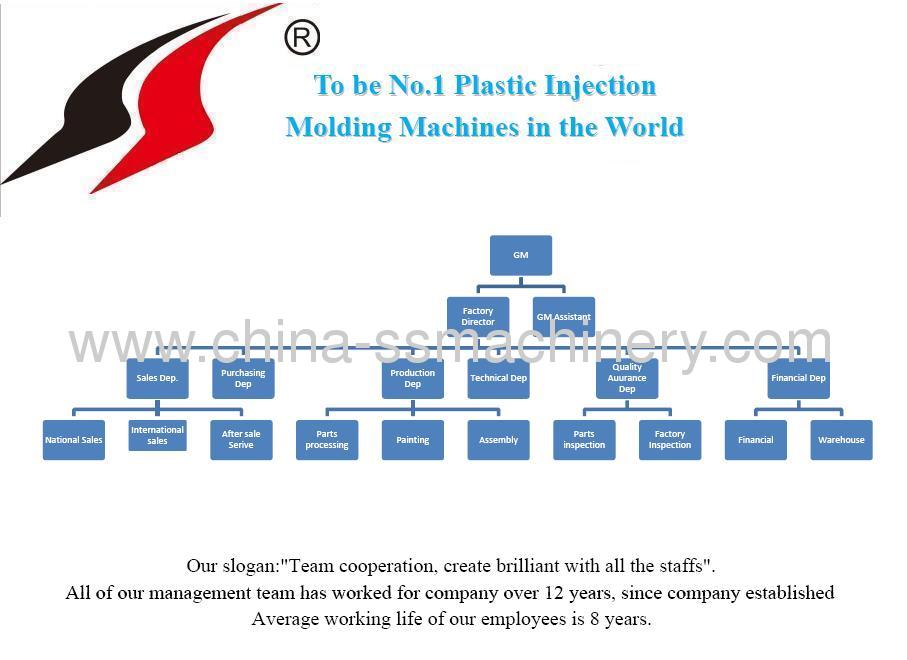

Organization chart of our plastic machinery;

We have established sales network in coutries Brazil,Argentina,Chile,Denmark,Poland,Turkey,Iran,Idonesia, welcome more distributors to join us.

| Parameters of SSF series plastic injection machines |

| Items | Parameter | Unit | Parameter Value (SSF250) | Parameter Value (SSF380) | Parameter Value (SSF500) | Parameter Value (SSF700) | Parameter Value (SSF900) | Parameter Value (SSF1180) | Parameter Value (SSF1480) | Parameter Value (SSF1680) |

| Injection Unit | Screw diameter | mm | A | B | A | B | A | B | A | B | A | B | C | A | B | C | A | B | C | A | B | C |

| 22 | 25 | 27 | 30 | 28 | 30 | 34 | 36 | 32 | 35 | 38 | 35 | 38 | 42 | 38 | 42 | 45 | 42 | 45 | 50 |

| Screw L/D ratio | L/D | 17.7 | 15.5 | 18.4 | 16.5 | 19 | 17.7 | 18.8 | 17.7 | 24.8 | 22 | 20 | 22 | 20.2 | 18.4 | 22.1 | 20 | 18.6 | 23.6 | 22 | 19.8 |

| shot volume(theoretical) | Cm3 | 30 | 38 | 48 | 58 | 70 | 80 | 113 | 127 | 112 | 134 | 158 | 163 | 192 | 235 | 226 | 277 | 318 | 311 | 357 | 441 |

| injection weight(PS) | g | 27 | 34 | 44 | 53 | 64 | 73 | 103 | 115 | 102 | 122 | 144 | 148 | 175 | 213 | 206 | 252 | 289 | 283 | 325 | 402 |

| injection rate | g/s | 25 | 32 | 35 | 43 | 43 | 49 | 86 | 96 | 90 | 107 | 126 | 89 | 105 | 128 | 94 | 115 | 132 | 138 | 160 | 196 |

| injection pressure | Mpa | 185 | 143 | 187 | 151 | 224 | 195 | 171 | 153 | 208 | 174 | 148 | 219 | 186 | 152 | 208 | 171 | 149 | 203 | 177 | 143 |

| screw speed | rmp | 165 | 170 | 200 | 180 | 220 | 210 | 185 | 180 |

| Clamping unit | clamp force | KN | 250 | 380 | 500 | 700 | 900 | 1180 | 1480 | 1680 |

| open stroke | mm | 150 | 235 | 250 | 270 | 290 | 350 | 380 | 435 |

| distance between tie bars (W*H) | mm | 240*190 | 240*240 | 290*270 | 315*300 | 360*320 | 370*370 | 410*410 | 460*460 |

| max mould thickness | mm | 220 | 270 | 300 | 320 | 380 | 380 | 450 | 520 |

| min mould thickness | mm | 80 | 80 | 100 | 150 | 150 | 150 | 160 | 180 |

| ejector stroke | mm | 40 | 60 | 65 | 80 | 80 | 120 | 120 | 135 |

| ejector force | KN | 13 | 17.5 | 20 | 27 | 31 | 38 | 50 | 50 |

| ejector number | PC | 1 | 1 | 1 | 1 | 5 | 5 | 5 | 5 |

| dia of mould location hole | mm | 55 | 80 | 100 | 100 | 125 | 125 | 125 | 125 |

| Others | max pump pressure | Mpa | 14 | 14 | 16 | 16 | 16 | 16 | 16 | 16 |

| pump motor power | KW | 3 | 4 | 5.5 | 7.5 | 9 | 13 | 13 | 18.5 |

| heating power | KW | 2.5 | 3.2 | 4.7 | 5.1 | 6 | 7.3 | 9.3 | 12.3 |

| machine dimension | m | 2.75*0.86*1.35 | 2.9*1.0*1.4 | 3.2*1.1*1.6 | 3.6*1.2*1.65 | 4*1.27*1.75 | 4.3*1.28*1.9 | 4.5*1.35*1.9 | 5.13*1.45*2.12 |

| machine weight | T | 1 | 1.35 | 1.9 | 2.2 | 2.9 | 3.4 | 4 | 6 |

| oil tank capacity | L | 85 | 90 | 115 | 130 | 150 | 230 | 250 | 300 |