China top quality injection molding machine manufacturer

Injection molding machine manufacturer, we supply all kinds of injection molding machines

Main technical parameters of 32T injection molding machine as below;

| Items | Parameter | Unit | Parameter Value (SSF320) |

| Injection Unit | Screw diameter | mm | A | B |

| 22 | 25 |

| Screw L/D ratio | L/D | 17.7 | 15.5 |

| shot volumn (theoretical) | Cm3 | 30 | 38 |

| injection weight(PS) | g | 27 | 34 |

| plasticizing capacity | g/s | 2.6 | 3.3 |

| injection rate | g/s | 25 | 32 |

| injection pressure | Mpa | 185 | 143 |

| screw speed | rmp | 165 |

| Clamping unit | clamp force | KN | 320 |

| open stroke | mm | 155 |

| distance between tie bars (W*H) | mm | 245*195 |

| max mould thickness | mm | 260 |

| min mould thickness | mm | 80 |

| ejector stroke | mm | 40 |

| ejector force | KN | 13 |

| ejector number | PC | 1 |

| dia of mould location hole | mm | 55 |

| Others | max pump pressure | Mpa | 14 |

| pump motor power | KW | 3 |

| heating power | KW | 2.5 |

| machine dimension | m | 2.80*0.86*1.35 |

| machine weight | T | 1 |

| oil tank capacity | L | 85 |

Main features of injection molding machines;

Double-cylinder balanced injection system;

Multi-stage pressure &speed injection;

Back pressure adjustment device;

Low pressure mold protection;

Single hydraulic core pulling and inserting;

Multiple hydraulic ejector knock-out;

Mechanical, electrical safety device;

Auto lubrication system;

Hydraulic pressure full proportional control;

Computer control system;

Molding data memory system;

Automatic mould adjust function.

Energy saving with variable pump;

Five-point inward moving toggle system ensure high rigidty and precision for mold clamping and also reducing stress and stain effects;

Oil pipelines are positioned for aesthetic appearance and easy for maintenance;

The moving platen is fitted with adjustable slide support system to improve platen parallelism and provide better tie bar and mould protection and lengthen the working lifetime;

Nozzle alignment is provided using a simple mechanism with fine adjustment for accurate centering.

Clamping unit of injection molding machine, the five-point inward moving toggle system ensure high rigidty and precision for mold clamping and also reducing stress and stain effects, with automatic mold height adjustment function.

Injection unit of small plastic injection molding machine;

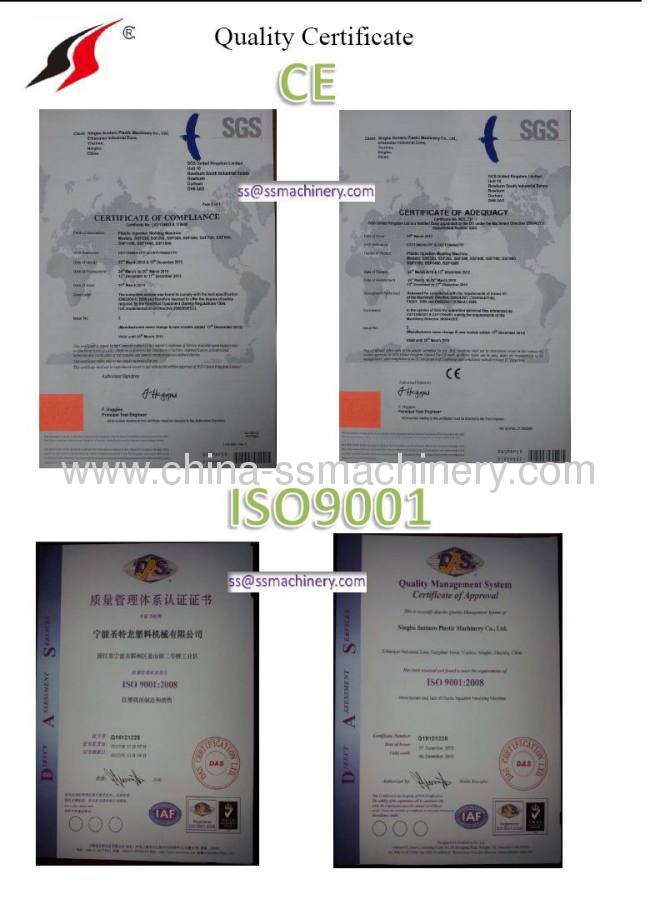

We make injection molding machines strictly follow ISO9001:2008 quality requirements, per customers's special requirements, CE also can be optional.

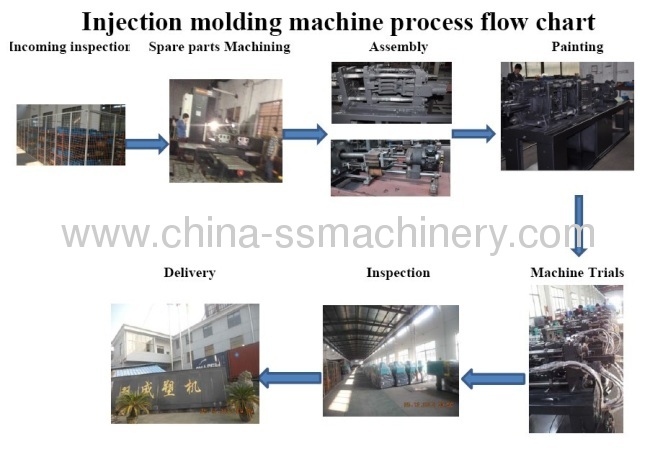

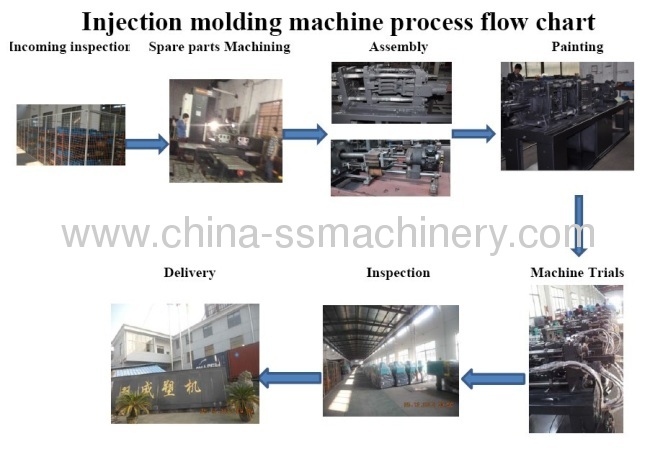

Injection molding machine manufacturing process, professional operators were assigned for each process;

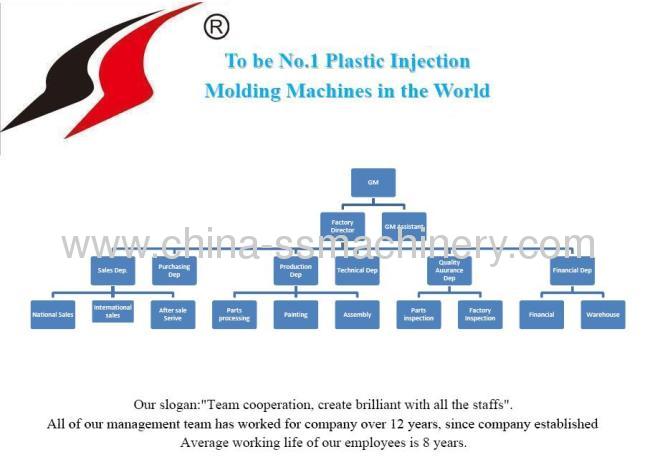

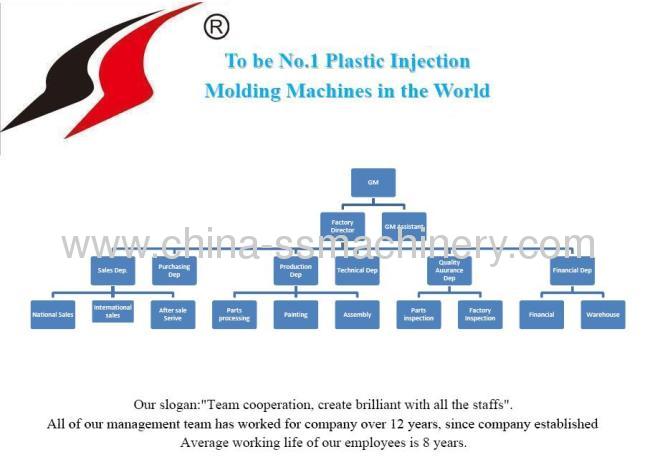

We Shuangsheng plastic machinery respects staffs and values partnership of each customer, each cooperators, that why we can grow smoothly and steadily even the international ecomonic situation is not so optimistic.

We Shuangsheng plastic machinery respects staffs and values partnership of each customer, each cooperators, that why we can grow smoothly and steadily even the international ecomonic situation is not so optimistic.

The orgnization chart of our company, average working life of the staffs is 8 years.

We Shuangsheng plastic machinery respects staffs and values partnership of each customer, each cooperators, that why we can grow smoothly and steadily even the international ecomonic situation is not so optimistic.

We Shuangsheng plastic machinery respects staffs and values partnership of each customer, each cooperators, that why we can grow smoothly and steadily even the international ecomonic situation is not so optimistic.