Servo plastic injection molding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SSF1680-S |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Shuangsheng |

| Power: | 50HZ |

| injection weight: | 325g |

| clamp force: | 1680kn |

| space between tie bars: | 460*460 |

| Min-max mould height: | 180~520 |

| Mold platen: | T-slot |

| Screw: | Bi-metal |

| Production Capacity: | 20sets/month |

| Packing: | nylon plastic bag in container |

| Delivery Date: | 30 days |

Product Description

Servo motor injection molding machine;

Servo motor plastic injection molding machine's features;

The servo system energy saving sets can be applied to any machine which is working with hydraulic system. With the energy saving sets your system will gain at least %30-70energy.

After the application of energy saving set your system, your machine will have the following advantages:

1. Energy saving will be %30-70 depending on the huydraulic system you have on your machine.

2. Because of the servo technology your pump will not work as your old system. As a result the oil temperature will not warm up as before. Both your pump and oil life will be longer.

3. Because of the low oil temperature the chiller of your system will not work as before. As a result you will save more energy.

4. Your retrifed machine will work much more silent.

5. As a result your system will gain energy more than 30%.

Parameters;

| Items | Parameter | Unit | Parameter Value (SSF1680) | ||

| Injection Unit | Screw diameter | mm | A | B | C |

| 42 | 45 | 50 | |||

| Screw L/D ratio | L/D | 23.6 | 22 | 19.8 | |

| shot volumn (theoretical) | Cm3 | 311 | 357 | 441 | |

| injection weight(PS) | g | 283 | 325 | 402 | |

| plasticizing capacity | g/s | 10 | 11.5 | 14.2 | |

| injection rate | g/s | 138 | 160 | 196 | |

| injection pressure | Mpa | 203 | 177 | 143 | |

| screw speed | rmp | 180 | |||

| Clamping unit | clamp force | KN | 1680 | ||

| open stroke | mm | 435 | |||

| distance between tie bars (W*H) | mm | 460*460 | |||

| max mould thickness | mm | 520 | |||

| min mould thickness | mm | 180 | |||

| ejector stroke | mm | 135 | |||

| ejector force | KN | 50 | |||

| ejector number | PC | 5 | |||

| dia of mould location hole | mm | 125 | |||

| Others | max pump pressure | Mpa | 16 | ||

| pump motor power | KW | 18.5 | |||

| heating power | KW | 12.3 | |||

| machine dimension | m | 5.13*1.45*2.12 | |||

| machine weight | T | 6 | |||

| oil tank capacity | L | 300 | |||

Plastic machinery characteristics;

Big tie bar space and shot weight capacity

World famous component parts

Competitive price and quality guarantee.

It can be widely used to produce all kinds of plastics parts, with characters of high efficiency and good performance.

Template structure of the high-rigidity design, both T-slots and conventional screw holes make mold is easy to install.

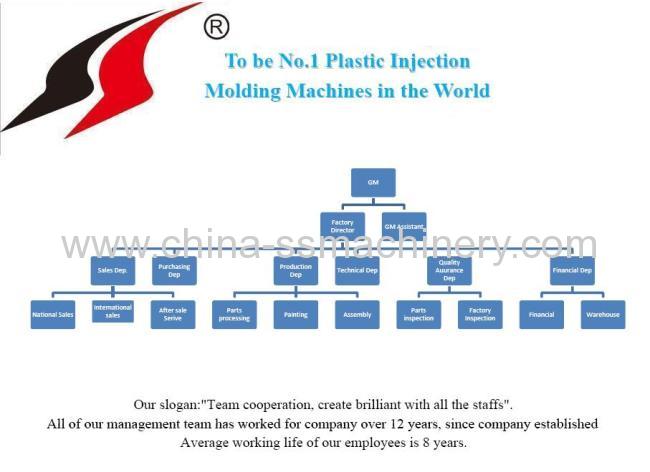

Organization chart of our company;

This machine can be widely to produce small capacity PET preforms, caps, PVC electrical socket and circuit, househould products and other plastic parts of which injection weight within 300grams.

PET preforms, 8 cavities of 500ML preforms;

Caps.12 cavities of neck dia 30mm;

PVC electrical sockets and circuit;