Horizontal energy saving plastic injection machine;

Parameters of 70T plastic machinery as below;

| Parameter | Unit | Parameter Value (SSF700) |

| Screw diameter | mm | A | B |

| 34 | 36 |

| Screw L/D ratio | L/D | 18.8 | 17.7 |

| shot volumn (theoretical) | Cm3 | 113 | 127 |

| injection weight(PS) | g | 103 | 115 |

| plasticizing capacity | g/s | 11.6 | 13 |

| injection rate | g/s | 86 | 96 |

| injection pressure | Mpa | 171 | 153 |

| screw speed | rmp | 180 |

| clamp force | KN | 700 |

| open stroke | mm | 270 |

| distance between tie bars (W*H) | mm | 315*300 |

| max mould thickness | mm | 320 |

| min mould thickness | mm | 150 |

| ejector stroke | mm | 80 |

| ejector force | KN | 27 |

| ejector number | PC | 1 |

| dia of mould location hole | mm | 100 |

| max pump pressure | Mpa | 16 |

| pump motor power | KW | 7.5 |

| heating power | KW | 5.1 |

| machine dimension | m | 3.6*1.2*1.65 |

| machine weight | T | 2.2 |

| oil tank capacity | L | 130 |

The plastic injection moulding machines features with;

Double-cylinder balanced injection system;

Multi-stage pressure &speed injection;

Back pressure adjustment device;

Low pressure mold protection;

Single hydraulic core pulling and inserting;

Multiple hydraulic ejector knock-out;

Mechanical, electrical safety device;

Auto lubrication system;

Hydraulic pressure full proportional control;

Computer control system;

Molding data memory system;

Automatic mould adjust function.

Energy saving with servo motor.

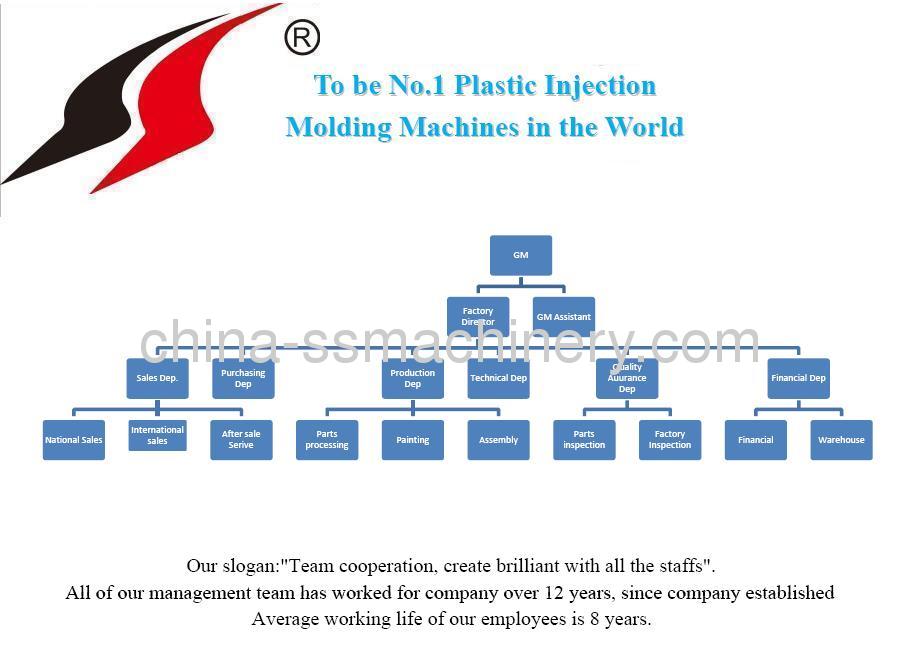

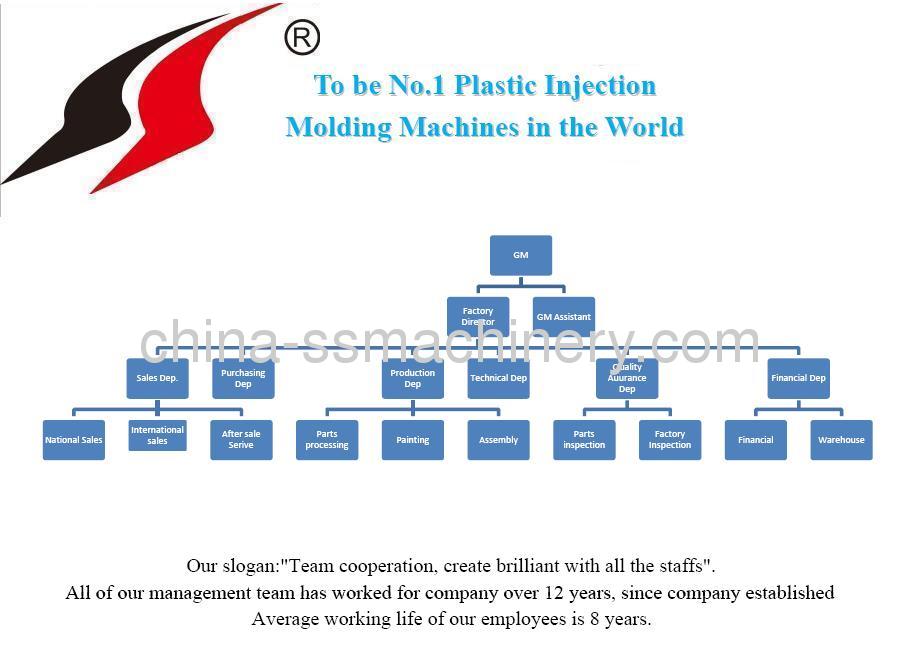

Our company empasis on team cooperation, we would like to find cooperators or distributors all around the world to help activate oversea markets together based on mutual benefits.

.jpg)