Servo motor small and precise injection moulding machine

38T plastic injection machine parameters as below;

| Parameter | Unit | Parameter Value (SSF380) |

| Screw diameter | mm | A | B |

| 27 | 30 |

| Screw L/D ratio | L/D | 18.4 | 16.5 |

| shot volumn (theoretical) | Cm3 | 48 | 58 |

| injection weight(PS) | g | 44 | 53 |

| plasticizing capacity | g/s | 4.3 | 5.9 |

| injection rate | g/s | 35 | 43 |

| injection pressure | Mpa | 187 | 151 |

| screw speed | rmp | 170 |

| clamp force | KN | 380 |

| open stroke | mm | 235 |

| distance between tie bars (W*H) | mm | 240*240 |

| max mould thickness | mm | 270 |

| min mould thickness | mm | 80 |

| ejector stroke | mm | 60 |

| ejector force | KN | 17.5 |

| ejector number | PC | 1 |

| dia of mould location hole | mm | 80 |

| max pump pressure | Mpa | 14 |

| pump motor power | KW | 4 |

| heating power | KW | 3.2 |

| machine dimension | m | 2.9*1.0*1.4 |

| machine weight | T | 1.35 |

| oil tank capacity | L | 90 |

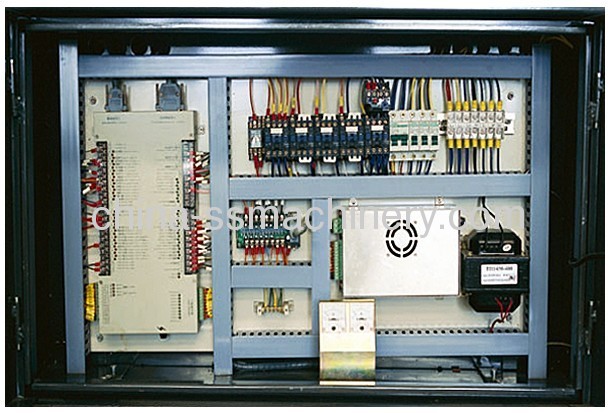

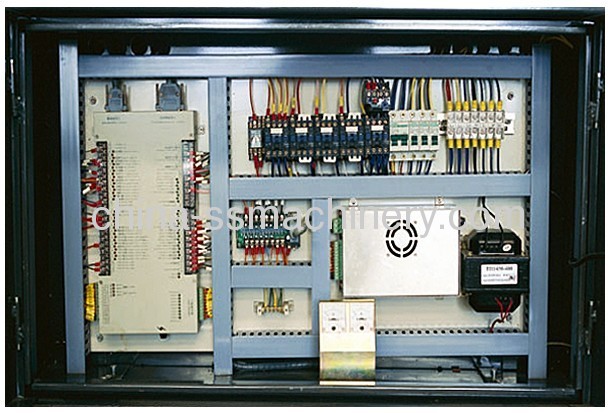

Open-type PLC interface technical edition & on-line amendment.

USB connection, copy, edition and amend procedure easily.

I/O automatically detect & use of ASIC to simplify circuit to ensure the reliability of PID closed-loop type of barrel heating & temperature deviation of the precise control of self-tuning.

Multilanguage selection with colorful screen,

The data stored without the requirement of battery, no need to worry lost datas