Computer controlled injection moulding machine;

Parameters of 140T servo motor plastic moulding machine as below;

| Parameter | Unit | Parameter Value (SSF1480) |

| Screw diameter | mm | A | B | C |

| 38 | 42 | 45 |

| Screw L/D ratio | L/D | 22.1 | 20 | 18.6 |

| shot volumn (theoretical) | Cm3 | 193 | 235 | 270 |

| injection weight(PS) | g | 176 | 213 | 246 |

| plasticizing capacity | g/s | 6.2 | 7.5 | 8.7 |

| injection rate | g/s | 94 | 115 | 132 |

| injection pressure | Mpa | 208 | 171 | 149 |

| screw speed | rmp | 185 |

| clamp force | KN | 1480 |

| open stroke | mm | 380 |

| distance between tie bars (W*H) | mm | 410*410 |

| max mould thickness | mm | 450 |

| min mould thickness | mm | 160 |

| ejector stroke | mm | 120 |

| ejector force | KN | 50 |

| ejector number | PC | 5 |

| dia of mould location hole | mm | 125 |

| max pump pressure | Mpa | 16 |

| pump motor power | KW | 13 |

| heating power | KW | 9.3 |

| machine dimension | m | 4.5*1.35*1.9 |

| machine weight | T | 4 |

| oil tank capacity | L | 250 |

You can choose several auxilaries for this plastic machine, we have reliable suppliers can provide.

Autoloader;

Hopper dryer;

Mold temperature controller;

Robot;

Water cooler;

Oil temperature controller;

Plastic dehumidizer;

Oil bypass filter;

Hopper magnet;

Mold clamps;

Water cooler

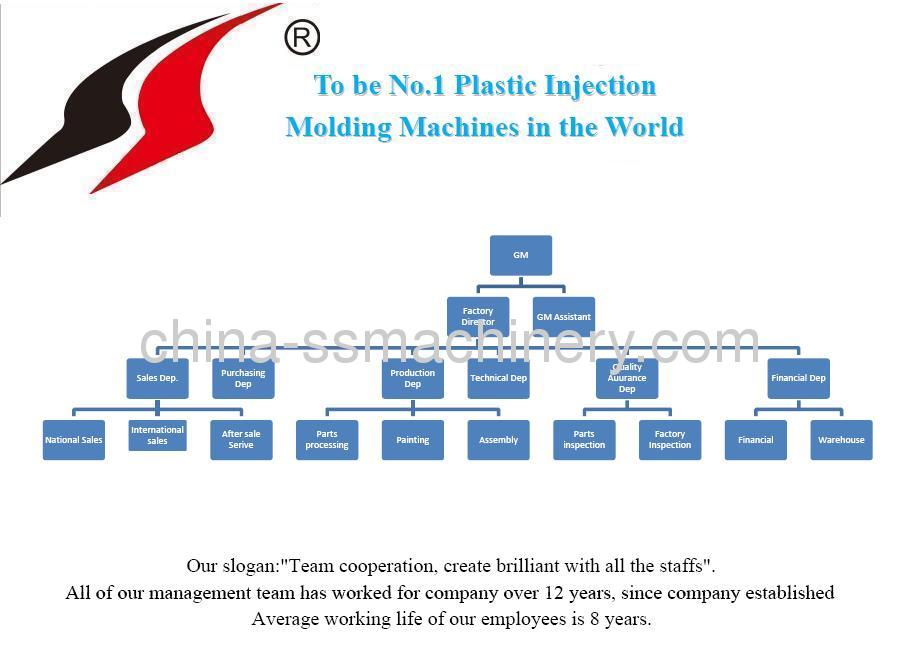

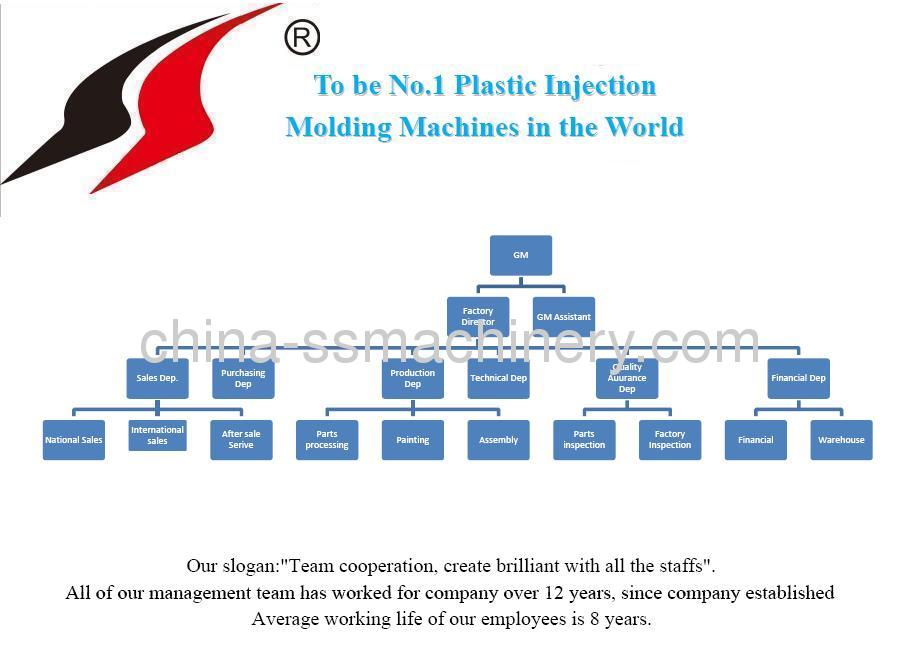

We shuangsheng plastic machinery respects staffs and values partnership of each customer, each cooperators, that why we can grow smoothly and steadily even the international ecomonic situation is not so optimistic.

The orgnization chart of our company, average working life of the staffs is 8 years.