Horizontal 38T injection molding machine

Parameters of plastic injection moulding machine as below;

| Parameter | Unit | Parameter Value (SSF380-K5) |

| Screw diameter | mm | A | B |

| 27 | 30 |

| Screw L/D ratio | L/D | 18.4 | 16.5 |

| shot volumn (theoretical) | Cm3 | 48 | 58 |

| injection weight(PS) | g | 44 | 53 |

| plasticizing capacity | g/s | 4.3 | 5.9 |

| injection rate | g/s | 35 | 43 |

| injection pressure | Mpa | 187 | 151 |

| screw speed | rmp | 170 |

| clamp force | KN | 380 |

| open stroke | mm | 235 |

| distance between tie bars (W*H) | mm | 240*240 |

| max mould thickness | mm | 270 |

| min mould thickness | mm | 80 |

| ejector stroke | mm | 60 |

| ejector force | KN | 17.5 |

| ejector number | PC | 1 |

| dia of mould location hole | mm | 80 |

| max pump pressure | Mpa | 14 |

| pump motor power | KW | 4 |

| heating power | KW | 3.2 |

| machine dimension | m | 2.9*1.0*1.4 |

| machine weight | T | 1.35 |

| oil tank capacity | L | 90 |

Injection unit of injection moulding machine;

The injection unit incorporates a Dual-pillar supporting system with balanced twin cylinder injection unit for evenly distributed force and rapid screw motion.

Nozzle alignment is provided using a simple mechanism with fine adjustment for accurate centeering.

High quality nitride or chrome plated alloy screw with a netrogen-treated barrel provides anti-corrosion with high wear resistance for an extended working life.

Quality Certificates of plastic injection moulding machines;

We manufacture machine upon ISO9001:2008 quality system, CE also optional for Europe market.

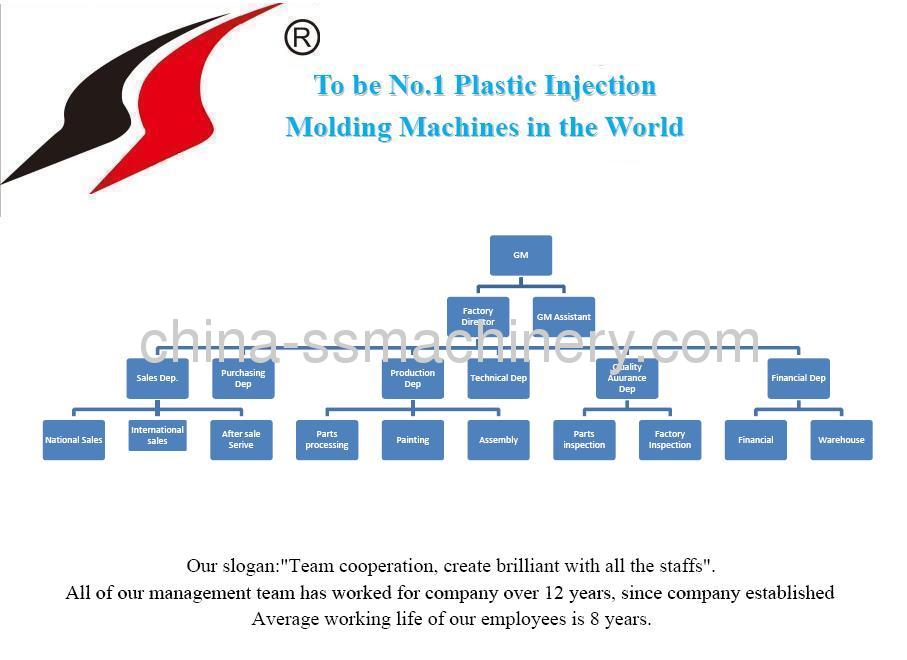

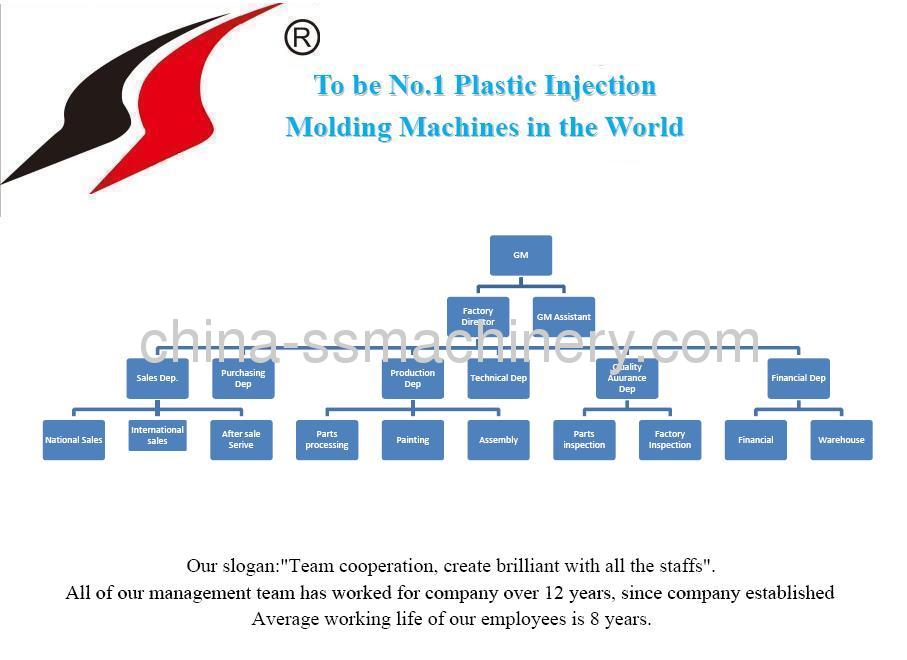

Organization chart of Shuangsheng brand plastic machinery;