17 1/4" OD Integral blade drill string stabilizer

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR |

| Payment Terms: | T/T |

| Supply Ability: | 200Ton/month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | 17 1/4" Stabilizer |

|---|---|

| Means of Transport: | Ocean |

| Spec.: | API 7-1 |

| Usage: | Oil well drilling |

| Material: | AISI 4145H |

| Condition: | Finish machining |

| Heat treatment: | Quenching & Tempering |

| Type: | Near Bit Stabilizer |

| Hardfacing: | HF 5000 |

| Process type: | Forging |

| Size: | 17 1/4" |

| Delivery: | 30 days |

| Production Capacity: | 200Ton/month |

| Packing: | for sea shipment |

| Delivery Date: | 30 days |

Product Description

17 1/4" OD Integral blade drill string stabilizer

API Drill string stabilizer

17-1/4"OD x 9-1/2" Body x 3" ID Integral Spiral Blade STRING

Stabilizer (270 deg wrap), c/w 7-5/8" Reg Box x 7-5/8" Reg Pin,

105" overall length,no boreback box,

No Hardfacing. Note: Finished OD of 17-1/4"

Hardfacing of the Integral blade stabilizer

HF1000 Crushed tungsten carbide held in a nickel bronze matrix. The 3mm grain size ensures greater concentration of

carbide which is ideal for soft formation drilling.

HF2000 Trapezoidal tungsten carbide inserts held in a sintered carbide nickel bronze matrix. This will give a greater depth

of carbide coverage -- ideal for high deviation drilling in abrasive formations.

HF3000 Tungsten carbide inserts set in a power spray deposit ideal for abrasive formation. 97% bonding guaranteed,

certified by ultrasonic report. Recommended for non-magnetic stabilizers.

TCI Tungsten carbide inserts (button type). The inserts have been developed to allow cold insertion and maintain close

fit. A greater concentration of inserts on the bottom third of the blade and leading edge will increase surface contact to

reduce wear in highly abrasive formations.

integral blade stabilizer, specifications:

HOLE SIZE | BODY OD. | FISHING | BLADE | BLADE | TONG | BORE | OAL |

8 | 43/4 | 30 | 15 | 3 | 25 | 21/4 | 72 |

81/2 | 61/2 | 30 | 18 | 3 | 27 | 213/16 | 78 |

121/4 | 8 | 30 | 18 | 31/2 | 28 | 213/16 | 83 |

121/4 | 91/2 | 30 | 18 | 31/2 | 28 | 3 | 83 |

143/4 | 8 | 30 | 18 | 31/2 | 30 | 213/16 | 90 |

143/4 | 91/2 | 30 | 18 | 31/2 | 30 | 3 | 90 |

16 | 91/2 | 30 | 18 | 31/2 | 30 | 3 | 92 |

171/2 | 8 | 30 | 20 | 31/2 | 30 | 213/16 | 94 |

171/2 | 91/2 | 30 | 20 | 31/2 | 30 | 3 | 94 |

20-26 | 91/2-11 | 30 | 22 | 4 | 30 | 3 | 110 |

Testing equipment

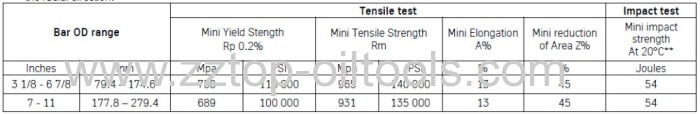

Mechanical properties:

17-1/4"OD x 9-1/2" Body x 3" ID Integral Spiral Blade STRING

Stabilizer (270 deg wrap), c/w 7-5/8" Reg Box x 7-5/8" Reg Pin,

105" overall length,no boreback box,

No Hardfacing. Note: Finished OD of 17-1/4"