7" RTTS Packer Retrievable full bore J slot Drill stem testing

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10sets/month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | DST - 7" RTTS Packer |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Working pressure: | 70Mpa |

| Woring Temperature: | 400F |

| Material: | AISI4140 |

| Standard: | NACE MR0175 |

| Type: | Fullbore |

| Operation: | Mechanical |

| Package: | Wooden |

| Status: | On Shelf |

| Condition: | New |

| Working condtion: | HPHT |

| Production Capacity: | 10sets/month |

| Packing: | plywood |

| Delivery Date: | 35days |

Product Description

Operation:

When starting the RTTS packer into the hole, place J-slot in the drag block sleeve in the locked position. The tool is run slightly below the desired setting position and is then picked up tool to setting position and rotated pipe several turns to right(on bottom, only 1/2 turn is required).Holding right torque in pipe, slack off the pipe weight until mechanical slips on the tool set and start taking weight .At the same time the packer element is compressed against the wall of the casing, then the packer can isolate the annular from the test zone. Self-guard hydraulic hold down mechanism can prevent the packer from bouncing up because of the high pressure below the packer. When it is extra, pressure can be into the annular space between the volume tube, hydraulic hold down body and the lower mandrel through the radial hole on the lower mandrel, then to reach the round hydraulic hold down slip and compress the slip retractor spring, then the round hydraulic hold down slip lean against the inside wall of the casing closely and help prevent the tool from being pumped up the hole.

When unsetting the packer,y ou must open the circulating valve to equalize across the packer, then the round hydraulic hold down slip to retract, raise tubing up, the pacer can be released. The index lug will ride automatically the ramp to the locking position.

No | Specifications | 7" | |||

1 | Casing Weight Range(lb/ft) | 7" 17-26lb/ft | 7" 23-29lb/ft | 7" 32-38lb/ft | 6-5/8" 17-20lb/ft |

2 | Packer Ring OD | 151.1mm | 144.8mm | 142.7mm | |

3 | Top Shoe OD | 152.4mm | 146.1mm | 143.5mm | |

4 | Min. ID of tool | 61mm | |||

5 | Length | 1380,1611,1598,1473,1554mm | |||

6 | Pressure differential across the pacing ring | 70MPa | |||

7 | Internal Yield Pressure strength (Bursting pressure) | 98.5MPa | |||

8 | External Yield Pressure strength (Collapse Pressure) | 92MPa | |||

9 | Tensile Strength(Yield) | 805.3KN | |||

10 | Torque Strength | 14.5KN·m | |||

11 | Service environment | Mud, Crude Oil, Natural gas with H2S and acid | |||

12 | Service temperature | --29oC~+204oC | |||

13 | End connections | 4 5/32-8UN.BX 2 7/8 TBG.P 3 7/8 CAS.BXP 3 1/2IF.BXP 3 7/8 CAS.B X 2 7/8 UP TBG.P 4 5/32-8UN.B X 3 7/8 CAS.P | |||

Packer parts:

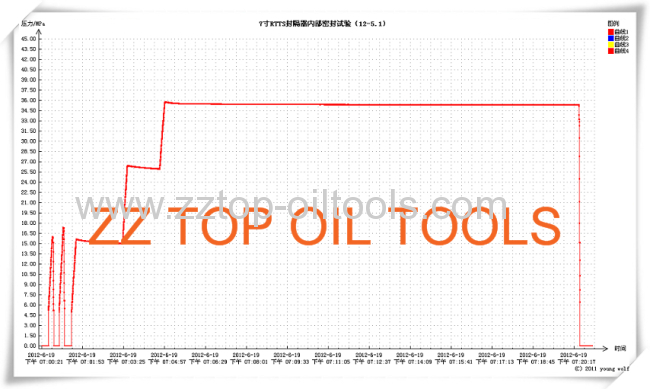

Testing chart