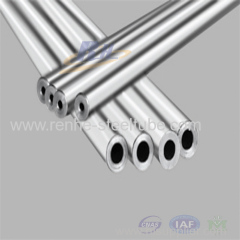

4mm Small Diameter High Precision Tube

| Min. Order: | 1 Ton |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500tons |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

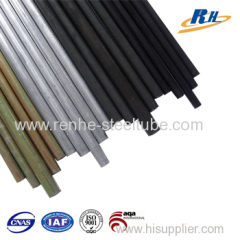

| Main Products: | Hydraulic Fluid Line Tube, Phosphated Metric Steel Tube, BA Steel Tube, Zinc Coated Steel Tube, High Pressure Oil Tube |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Production Capacity: | 500tons |

| Packing: | bundled and wrapped with plastic, wooden case or as your requirement |

| Delivery Date: | within 20 working days after receiving deposit |

Product Description

4mm Small Diameter High Precision Tube

1. Description

DIN2391 St37.4 Material Cold Drawn Carbon Seamless Pipe flexibility. It is popular in hydraulic applications such as oil and water conveying and pneumatic applications. DIN2391 St37.4 Material Cold Drawn Carbon Seamless Pipe is not suitable for load bearing applications.

Our DIN2391 St37.4 Material Cold Drawn Carbon Seamless Pipe is supplied in full compliance with the Standard DIN2391/C EN 10305-4. Typical lengths available are 3 metre and 6 metre, but should you need a different size please let us know when place orders.

2. Specification of DIN2391 St37.4 Material Cold Drawn Carbon Seamless Pipe

2.1 Dimensions

Tubes shall be ordered:

2.1.1. by outside diameter and inside diameter

2.1.2. by outside diameter and wall thickness

2.2 Tolerances

2.2.2. Tolerances by agreement

2.2.3. Dimensions and tolerances according to standard ASTM A450

2.4 Delivery conditions and heat treatment

BK (+C) Cold finished/hard (cold finished as drawn). No heat treatment after the last cold forming process

BKW (+LC) Cold finished/soft (lightly cold worked). After the last heat treatment there is a light finishing pass (cold drawing).

BKS (+SR) Cold finished/stress relieve annealed. After the final cold forming process the tubes are stress relieve annealed.

GBK (+A) Annealed. After the final cold forming process the tubes are annealed in a controlled atmosphere

5 Surface condition

Tube surface corresponds to the standards and depends on the method of tube manufacturing and method of heat treatment. Value of roughness Ra <0.8 µm.

2.6 Tube ends

The tubes are delivered with plain ends without burrs at the ends of the tube.

Upon request ends could be plugged with plastic caps

3.Testing of DIN2391 St37.4 Material Cold Drawn Carbon Seamless Pipe

Testing is performed in accordance with corresponding standards or by agreement

• flattening test , drift expanding test, flaring test, bending test

• mechanical properties test

• NDT for detection of transverse imperfections and wall imperfections .

4. Packing and Protective coating

4.1 Tubes are supplied either uncoated or with the manufacturers standard mill coating at the option of the customer (subject of agreement between customer and manufacturer

Hi,this is Chrisina,thanks very much for your interest in our products,If you want such steel tubes and pipes,or the standard is not listed above,pls do not hesitate to contact me at once.pls tell me,it's my honor to service you!

Christina Skype: christina.haibinjx

Tel:+8618056100777