Seamless Carbon Steel Mechanical Tubing

1000.0~3000.0 USD

| Min. Order: | 500 Meter |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 500Ton/ Month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Hydraulic Fluid Line Tube, Phosphated Metric Steel Tube, BA Steel Tube, Zinc Coated Steel Tube, High Pressure Oil Tube |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| EN: | ASTM A19 |

| DIN: | DIN2391 part 2 |

| Steel Gr.: | St37, St45, St52, 1010,1020,4130 |

| Condition: | NBK, Normalizing |

| Surface treatment: | Bright annealed |

| Ends: | capped |

| Name: | Seamless Carbon Steel Mechanical Tubing |

| Packing: | wooden case |

| Using: | automobile |

| Production Capacity: | 500Ton/ Month |

| Packing: | Wooden case or as per requirement |

| Delivery Date: | 15working days |

Product Description

Seamless Carbon Steel Mechanical Tubing

1. Descripition of Seamless Carbon Steel Mechanical Tubing

the steel billets is from Baosteel, Xingcheng Special Steel or Huaisteel, we do 100% visual inspection and chemical inspection randomly, then bars were cut into short pcs as per requirement of final tube length requirement to do hot piercing, the whole processing flow chart of seamless pipe as below:

2. Specification of Seamless Carbon Steel Mechanical Tubing

Tubes shall be ordered:

2.1.1. by outside diameter and inside diameter

2.1.2. by outside diameter and wall thickness

2.2 Tolerances

2.2.1. Values according to standards

2.2.2. Tolerances by agreement

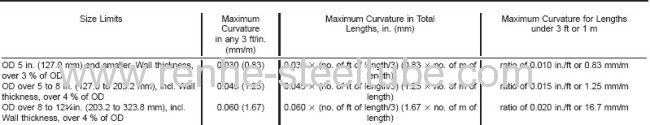

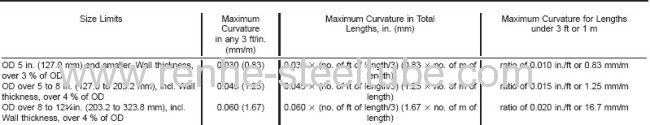

2.2.3. Dimensions and tolerances according to standard ASTM A450

2.3 Steel grades

Steel is produced in electric arc furnace and is fully killed.

Chemical compositon as per ASTM A519 requirement

2.4 Delivery conditions and heat treatment

2.5 Surface condition

Tube surface corresponds to the standards and depends on the method of tube manufacturing and method of heat treatment.

2.6 Tube ends

The tubes are delivered with plain ends without burrs at the ends of the tube.

Upon request ends could be plugged with plastic caps

3. Packing and Protective coating

3.1 Tubes are supplied either uncoated or with the manufacturers standard mill coating at the option of the customer (subject of agreement between customer and manufacturer).

3.2 Packaging of Seamless Carbon Steel Mechanical Tubing

Tubes are packed in round or hexagonal bundles with weight max.2000 kg. Other possibilities by agreement.

4. Mill Test Certificate

Types of inspection documents according to EN 10204 3.1.B Inspection certificate

5. Quality System(ISO9001&TS16949)

7. Quality Control