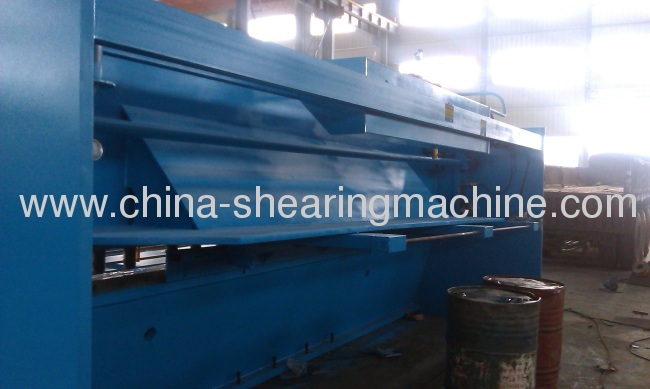

Hydraulic shearing machine QC11Y-6x6000 NC guillotine shears

26866.0~31428.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Set/Sets per Month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Nantong, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Shearing Machine, Bending Machine, Plate Rolling Machine, Section Bending Machine, Hydraulic Ironworker |

Product Detail

| Model No.: | QC11Y-6x6000 |

|---|---|

| Means of Transport: | Ocean, Land |

| Voltage: | 11KW |

| Rated Power: | 380V/50Hz |

| Dimension(L*W*H): | 6560x2350x2700 |

| Weight: | 16600kg |

| Quality Certification: | CQC,ISO9001:2008 |

| Safety Certification: | CE Certification |

| Shearing angler: | 0.5-2.5 |

| Strokes: | 5-25 |

| Shearing thickness: | 6mm |

| Shearing width: | 6000mm |

| Production Capacity: | 30 Set/Sets per Month |

| Packing: | PVC plastic,with steel pallet |

| Delivery Date: | Within 35-45 days after received the deposit |

Product Description

- Holistic welding structure treated by annealing.

- The top rest does the linear motion under the hydraulic cylinder′s drive.

- Both the upper and lower blades are rectangular,and the blade clearance can be rapidly adjusted manually or electrically.

- Time relay controls shearing stroke and shearing angles are adjusted electrically.

- The forward and backward movement of the back gauge is motorized and indicated by a digital display,while fine adjustments are also available.

- All major electrical and hydraulic elements are assembled with high grade international brands.

- A light alignment device makes shearing much easier and more efficient.

- Pneumatic back support is optional.

CNC Machines Only:

- CNC system controls ram and back gauge movement.

- Blade clearance, shearing angle and shearing length are calculated and controlled automatically by CNC system.

Model | Cutting Thickness (mm) | Cutting Width (mm) | Cutting Angle (°) | Throat Depth (mm) | Number of Stroke (min-1) | Back Gauge Range (mm) | Main Motor Power (Kw) |

QC11Y-6×2500 | 6 | 2500 | 0.5~1.5° | 100 | 17 | 20-600 | 7.5 |

QC11Y-6×3200 | 6 | 3200 | 0.5~1.5° | 100 | 14 | 20-600 | 7.5 |

QC11Y-6×4000 | 6 | 4000 | 0.5~1.5° | 100 | 10 | 20-600 | 7.5 |

QC11Y-6*5000 | 6 | 5000 | 0.5~2° | 100 | 7 | 20-600 | 7.5 |

QC11Y-6×6000 | 6 | 6000 | 0.5~2° | 100 | 6 | 20-600 | 11 |

QC11Y-8×2500 | 8 | 2500 | 0.5~1.5° | 100 | 14 | 20-600 | 11 |

QC11Y-8×3200 | 8 | 3200 | 0.5~2° | 100 | 10 | 20-600 | 11 |

QC11Y-8×4000 | 8 | 4000 | 0.5~2° | 100 | 8 | 20-600 | 11 |

QC11Y-8×6000 | 8 | 6000 | 0.5~2° | 100 | 6 | 20-600 | 11 |

QC11Y-10×2500 | 10 | 2500 | 0.5~1.5° | 100 | 10 | 20-600 | 11 |

QC11Y-10×3200 | 10 | 3200 | 0.5~2° | 100 | 10 | 20-600 | 11 |

QC11Y-10×4000 | 10 | 4000 | 0.5~2° | 100 | 12 | 20-600 | 11 |

QC11Y-12×2500 | 12 | 2500 | 0.5~2° | 100 | 10 | 20-800 | 15 |

QC11Y-12×3200 | 12 | 3200 | 0.5~2° | 100 | 10 | 20-800 | 22 |

QC11Y-12×4000 | 12 | 4000 | 0.5~2° | 100 | 7 | 20-800 | 22 |

QC11Y-12×6000 | 12 | 6000 | 0.5~2° | 100 | 5 | 20-800 | 22 |

QC11Y-16×2500 | 16 | 2500 | 0.5~2° | 100 | 8 | 20-800 | 22 |

QC11Y-16×3200 | 16 | 3200 | 0.5~2° | 100 | 7 | 20-800 | 22 |

QC11Y-16×4000 | 16 | 4000 | 0.5~2.5° | 100 | 6 | 20-800 | 22 |

QC11Y-20×2500 | 20 | 2500 | 0.5~2.5° | 100 | 6 | 20-800 | 30 |

QC11Y-20×3200 | 20 | 3200 | 0.5~3° | 100 | 5 | 20-800 | 30 |

QC11Y-20×4000 | 20 | 4000 | 0.5~3° | 100 | 5 | 20-800 | 30 |

QC11Y-25×2500 | 25 | 2500 | 0.5~3° | 100 | 5 | 20-800 | 37 |

QC11Y-25×3200 | 25 | 3200 | 0.5~3° | 100 | 5 | 20-800 | 37 |

QC11Y-30×2500 | 30 | 2500 | 0.5~3° | 100 | 4 | 20-1000 | 45 |

QC11Y-30×3200 | 30 | 3200 | 0.5~3° | 100 | 4 | 20-1000 | 45 |

Description and specifications given in this catalogue are subject to modification without notice.

Standard Equipment | |

QC11Y Series | QC11K Series |

ESTUN E10 NC System | DELEM DAC-310 CNC System |

OMG Hydraulic Valve | REXROTH or HOERBIGER Hydraulic Valve |

Chinese Well-known Brand Motor | SIMENS Motor |

Chinese Well-known Brand Pump | Chinese Well-known Brand Pump |

Main Electrical: SIEMENS OR SCHNEIDER | Main Electrical: SIEMENS OR SCHNEIDER |

Back Gauge: Conventional Screw | Back Gauge: Ball Screw & Linear Guides |

Seals: NOK or PARKER | Seals: NOK or PARKER |

Standard Blade | Standard Blade |

Lights with shadow line | Lights with shadow line |

Ball roller worktable | Ball roller worktable |

Front Support Arms with Measurement | Front Support Arms with Measurement |

Front-Standard fence | Front-Standard fence |

Foot control switch | Foot control switch |

Manual quick blade clearance adjustment | YASKAWA Servo Motor Drive |

Manual cutting angle adjustment | |

Optional Equipment | |

QC11Y Series | QC11K Series |

NC system: SIKO | DELEM DAC 360 |

SIMENS Motor | CYBELEC DNC 61G |

REXROTH or HOERBIGER Hydraulic Valve | CYBELEC Touch 6 |

Back Gauge: Ball Screw & Linear Guides | REXROTH or HOERBIGER Pump |

Pneumatic rear support | Pneumatic rear support |

Optical Protection | Optical Protection |

QC11Y-6x6000 NC hydraulic guillotine sheariing machine,guillotine shear,cutting machine,shearing machine,sheet cutter,