Angle roller,section bending machine

5420.0~6360.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Set/Sets per Month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Nantong, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Shearing Machine, Bending Machine, Plate Rolling Machine, Section Bending Machine, Hydraulic Ironworker |

Product Detail

| Model No.: | W24Y-1000 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | Xingte |

| Machine Type: | Roller-Bending Machine |

| Raw Material: | Sheet / Plate Rolling |

| Material / Metal Processed: | angle steel ,flat steel,channel steel,pipes |

| Power: | 5.5KW |

| Automation: | Automatic |

| Extra Services: | Machining |

| Production Capacity: | 30 Set/Sets per Month |

| Packing: | Covering with colour cloth,with steel tray |

| Delivery Date: | 25 workdays |

Product Description

Section bending machine,angle roller, Hydraulic Automatic Stainless Steel angle roller machine

Angle roller machine,section bender,section bending machine

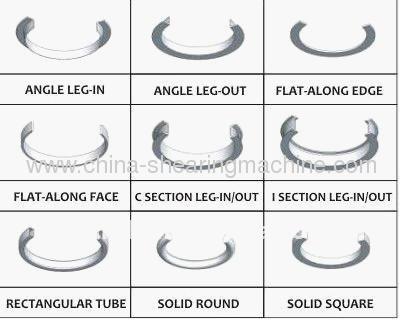

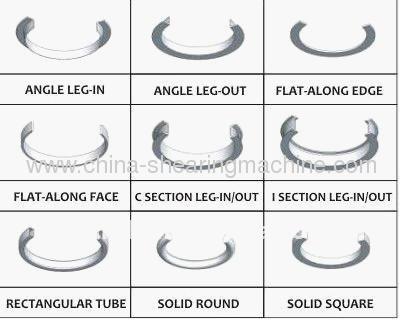

The machine is an efficient processing machine which is specially designed to bend and roll angle steel,flat steel,I steel,U steel,flat beam,tube,pipe,solid bar.etc.It has three working rollers, the positions of the two bottom rollers can be adjusted along the arc.assisting rollers are installed on both sides of the machine to control the work quality in the bending of proportional steel sections.The machine is reliable to operate with various functions and is an ideal bending machine that's adjustable and able to deal with different types of materials and specifications only by recombining the die settings,This removes the need to change dies.The machine offers low cost with flexibility and reliability.

Main specifications

Material yield limitation 250MPa

Top roller shaft φ110mm

Bottom roller shaft φ760mm

Mould material 42CrMo

Mould diameter φ250mm

Bottom rollers distance 520mm

Rolling speed 4-5m/min

Motor 5.5KW

Gear reducer China famous brand

Machine over dimension 1320*1250*1670mm

Machine weight 3360kg

1) Min. Bending Diameter: 700mm

2) Max. Capacity: Angle Bar Length =76mm x 12mm;

3) Motor: 5.5KW

4) Model Size (L x W H)mm: 1500*1300*1000mm

5) Phase: 3phase (380 V)

6) Weight: 3360KG

FEATURES OF THE MACHINE

Motorized Drive of both Bottom Rolls.

Standard Roll Set.

Hardened Precision Threaded Shaft.

Adjustable Lateral Guides.

Emergency Stop.

Foot Pedal for Right and Left Rotation, Option of Reverse-Forward Starter.

Manual Adjustment of Upper Roll.

Hardened Rolls for Standard Profile.

Easy and Quick Roll Change.

Scale for Clear Adjustment of Top Roll.

All Shafts Run in Roller Bearings.

The Machine Frame is Welded Steel Construction.

Heavy Duty and Rigid Construction

Machine can be Operated by Semi-Skilled or Unskilled Operator.

These machines can bend wide range of structural steel section,Flat bars, Solid Square or Round, Angle Iron (Leg In or Out), Round Tube, Square Tube, Rectangular Tubing.