●Size Tolerances |

Standard | OD Tolerance | WT Tolerance | API 5CT | D≤101.6mm | ±0.79mm | | -12.5% | D≥114.3mm | +1%-0.5% | | -12.5% | |

|

●Mechanical properties |

Standard | Steel | Tensile Strength(MPa) | Yield strength(MPa) | Elongation (%) | Min | Max | API 5CT | J55 (37Mn5) | 517 | 379 | 552 | As per table | K55 (37Mn5) | 655 | 379 | 552 | As per table | N80 (36Mn2V) | 689 | 552 | 758 | As per table | L80 (13Cr) | 655 | 552 | 655 | As per table | P110 (30CrMo) | 862 | 758 | 965 | As per table |

|

●Chemical composition: (%): |

Standard | Steel | C | Si | Mn | P≤ | S≤ | Cu≤ | Ni≤ | Cr≤ | Mo≤ | V≤ | API 5CT | J55 (37Mn5) | 0.34-0.39 | 0.20-0.35 | 1.25-1.50 | 0.020 | 0.015 | 0.20 | 0.20 | 0.15 | / | / | K55 (37Mn5) | 0.34-0.39 | 0.20-0.35 | 1.25-1.50 | 0.020 | 0.015 | 0.20 | 0.20 | 0.15 | / | / | N80 (36Mn2V) | 0.34-0.38 | 0.20-0.35 | 1.45-1.70 | 0.020 | 0.015 | 0.20 | 0.20 | 0.15 | / | 0.11-0.16 | L80 (13Cr) | 0.15-0.22 | 1.00 | 0.25-1.00 | 0.020 | 0.010 | 0.20 | 0.20 | 12-14 | / | / | P110 (30CrMo) | 0.26-0.35 | 0.17-0.37 | 0.40-0.70 | 0.020 | 0.010 | 0.20 | 0.20 | 0.8-1.1 | 0.15-0.25 | 0.08 |

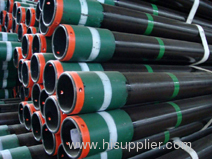

TUBING AND CASING

|

CONTACT:SKYPE:zyfittings99