best parallel twin barrel and screws

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 350 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Nitrided Feed Screw Barrel, Extrusion Screw And Barrel, Bimetallic Screws And Barrel, Twin Screw And Cylinder, Parallel Twin Screw Barrel |

Product Detail

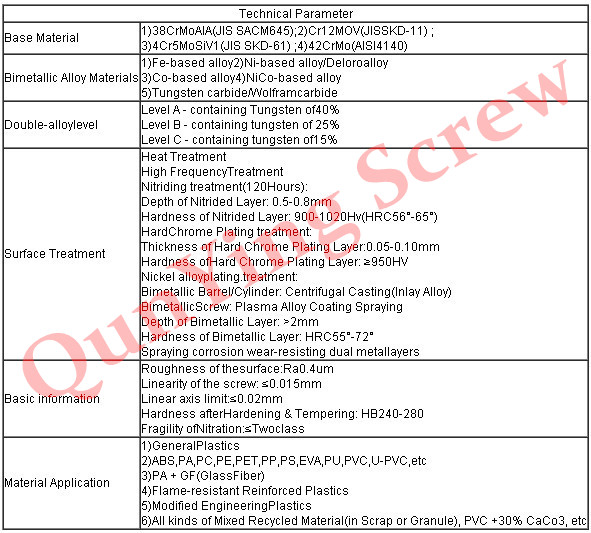

| Model No.: | QY-20131219P1 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | QunYing |

| Power: | 4-150KW |

| Bimetallic Screw Process: | Spray Welding |

| Base Material: | 38CrMoAlA,SACM645,ect. |

| Bimetallic Barrel Process: | Centrifuge Casting |

| Nitrided layer depth: | 0.5-0.8mm |

| Surface roughness:: | Ra0.4um |

| Bimetallic: | Fe-based,Ni-based,Tungsten Carbide(Wc) |

| Application: | Proflie,PVC/PE/PP Granules/profiles/Foaming... |

| End products: | WPC, proflie, pipe film etc. |

| Desigh: | As BAUSANO/KraussMaffei/Cincinnati/Battenfeld... |

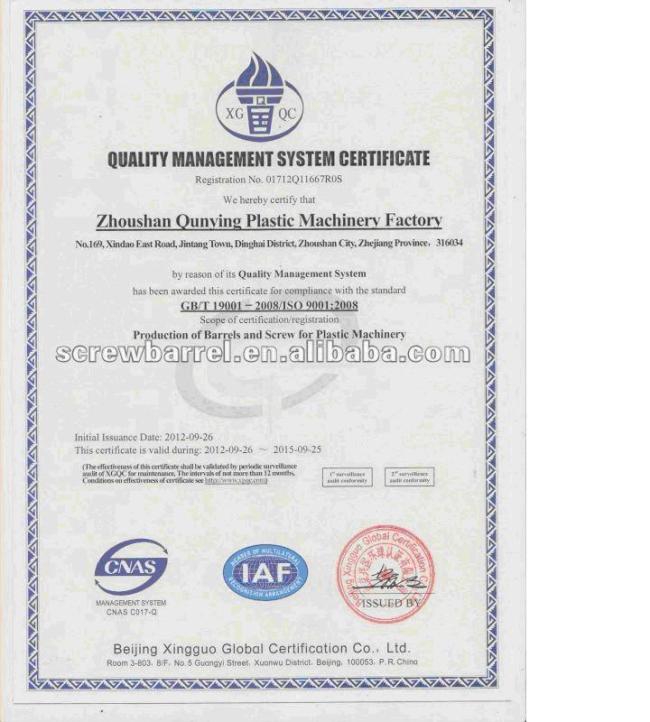

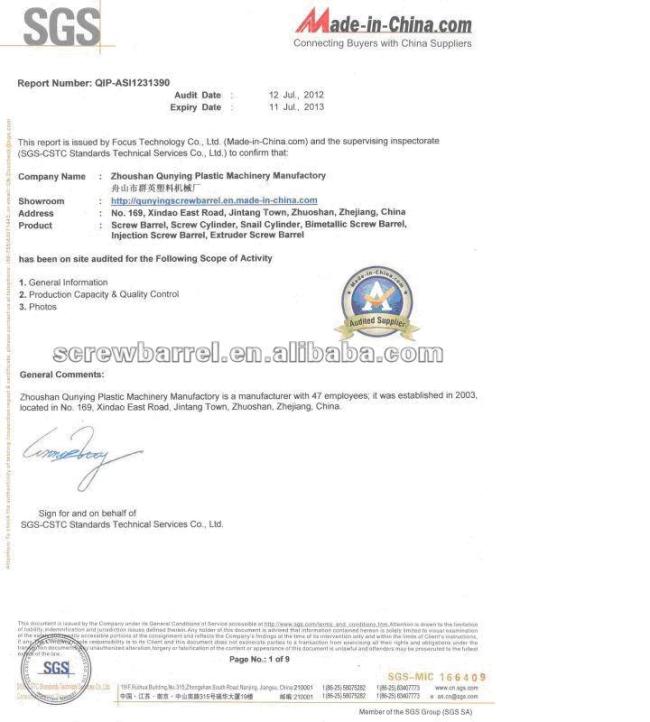

| Certificates: | GB/T19001-2008/ISO9001:2008/SGS |

| Production Capacity: | 350 sets per month |

| Packing: | Wooden Box (Exported Standard) |

| Delivery Date: | within 28 days |

Product Description

Parallel twin barrel and screws are widely used in producing pipe,cable,plate,profile and ect with plasticmaterial pvc+caco3,WC pp pe and ect.

All our extruder parallel twin bimetallic screw barrel adopt the high quality 38crmoala as the basicmaterial,but that could change if you want.

Our manufactory have been already passed the ISO 9001:2008 and SGS certificate.

We have sparying bimetallic on theejection of The parallel twin bimetallic screw barrel.

Dimension Avaliable

bimetallic Parallel twin barrel and screws---Screw Diameter :55/2,65/2,70/2,80/2,88/2,90/2,100/2,110/2,130/2...

We also could produce unconventional parallel twin screw barrel,and our engineer could design the screwaccording to your plastic material and products.

And our manufactory even have many parallel twin screw barrel designs of word-famous brand: such asCINCINNATI,BATTENFELD,KRUSSMAFFEI,BAUSANO,WEBER,AMUT....

So dear customer,if you are need to change your parallel twin screw barrel recently,please contact us! wecould satified you.

Material

Normal Material we use as following:

1.38CrMoAlA(JIS SACM645),( this are the best common material in producing parallel twin screw barrel)

2.Cr12MOV(JIS SKD-11)

3.4Cr5MoSiV1(JIS SKD-61)

4.42CrMo(AISI 4140)

The foreign material we used as following:

1. Germanysteel, GH113 ,2250 ,2842 ,1.8509 ,1.442 ,1.6582 ,1.6523 ,1.2080,1.4542,

2. USA steel, P20,420,L6,H13,W110,D3,A2,D6,O1,S1,M35,8620,3115,K52440

3. Sweden steel, 718S,718H,S136,S136H,STAVAX,ASP-23,ASP-30

4. Australia Steel, M202,M300,W302,K460,W300,K900,K100,W321

5. Hardnesssteel, YG6X,YG 6A,YG 6,YG8N,YG8,YG8C,YG11C,YG 15,YT5,YT14,YT30

6. Japan Steel, SKT 4,YXM 4,YXM 42,SNC 815,SK -3,SKS 3,and etc.

Advantage of parallel twin barrel and screws

1. Extruder bimetallic parallel twin barrel and screws has the advantage of lower rotation speed, smaller shearstress between the small screw

2. Good plasticization, high productivity, small shear force, stable pressure , less wear and tear and lowcost.

3. Extruder parallel twin barrel and screws is widely used in PVC products processing, especially for theproduction of PVC products with the output over 350Kg / h, because the parallel twin screw barrel costs lessthan conical twin-screw and barrel while it has more mature technology.

4. Extruder parallel twin barrel and screws is successfully applied in PVC plate, pipe, profile, pellet and mould, atthe same time, it solved the technical problem of low foaming, high foaming, high filling, wear and corrosion

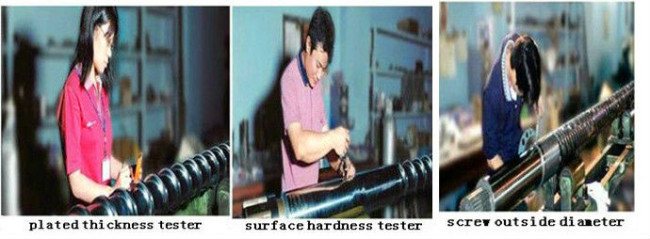

Customer visiting our company:

Custormer's feedback

Our Certificate:

Our Certificate:

Jerry will serve for you at any time,please contact me,thank you!