Extrusion screw & barrel

100.0~20000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Nitrided Feed Screw Barrel, Extrusion Screw And Barrel, Bimetallic Screws And Barrel, Twin Screw And Cylinder, Parallel Twin Screw Barrel |

Product Detail

| Model No.: | QY-109 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Extrusion screw & barrel |

| Base material: | JIS SACM645,AISI 4140,SKD61,SKD11 ect. |

| Nitrided Case Depth:: | 0.5-0.8mm |

| Bimetallic Depth: | 2-4mm |

| Diameter: | 20,25,35,45,55,65,75,85,95,105,115,125,135 |

| Hardness: | HRC56-65 |

| Application 1: | Pipe, film, profile, sheet, pvc pe/pew pc pelleting etc |

| Application 2: | ABS,PVC,PP/PE,PET,Engineering Plastic,GF,ect |

| Extruder machine: | Extrusion screw & barrel |

| Advantages: | Wear resistant and corrosion resistant |

| Certificates: | GBT 19001-2008/ISO9001:2008/SGS |

| Production Capacity: | 1000 sets per month |

| Packing: | AA Grade Wooden Case |

| Delivery Date: | 25 Days |

Product Description

Extrusion screw & barrel

Specification:

Dia. 15-300 mm Length 300-9000 mm L/D ratio: 15-50

Grade available:

1. Standard grade: 38CrMoAlA + nitriding 96 hours

2. Bimetallic grade: 38CrMoAlA + bimetallic alloy

3. TC-A grade: Tungsten carbide 40%

4. TC-B grade: Tungsten carbide 25%

5. TC-C grade: Tungsten carbide 9.5%

Techinical information :

Depth of Nitrated Layer: 0.5-0.8mm

Heat treatment: Nitriding 96 hours

Fragility of nitration: Less than grade 2

Hardness of nitration:HV900-1060 (HRc56°-65°)

Roughness of the surface:Ra 0.4μm

Screw straightness: 0.015mm/m

Chrome plating thickness: 0.01-0.1mm

Alloy Hardness:HRC58-62

Alloy Depth:>2mm

Common Nitrided:1-2years;Bimetallic: much longer lifetime.

Our inspection for extusion screw barrel:

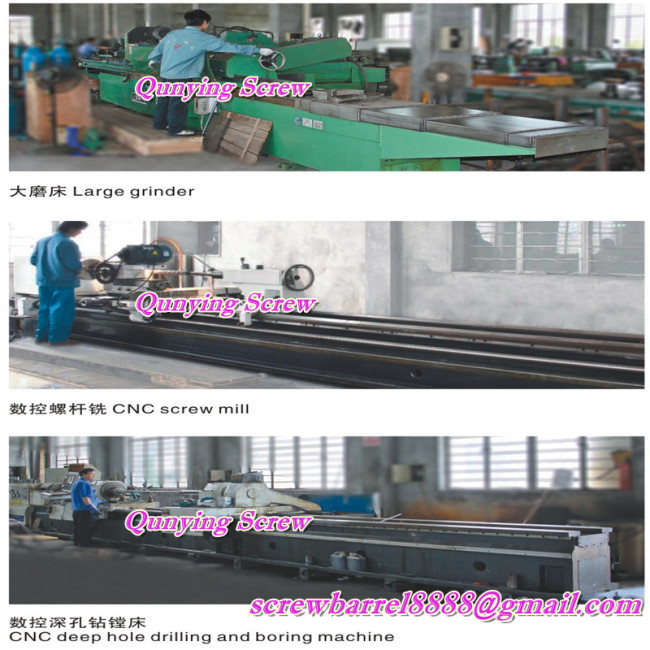

Qunying facotry:

As the best supplier,Qunying aslo make any specifcation of screw barrel for Haitian, Demag, Engel, Klauss maffei, Battenfeld, Nigro bossi, Arburg, NPM, BOY, Husky, Fanuc, Billion, Sumitomo, Nippon Steel, Toshiba, Nissei, Toshiba, Mitsubishi etc.