SJSZ 65/132 bimetallic conical screw barrel

1000.0~20000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Nitrided Feed Screw Barrel, Extrusion Screw And Barrel, Bimetallic Screws And Barrel, Twin Screw And Cylinder, Parallel Twin Screw Barrel |

Product Detail

| Model No.: | QY-CB03 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Plastic Type: | PVC |

| Use: | Others |

| Shaft Design: | Double |

| Brand Name: | QunYing |

| Power: | 14-120KW |

| Base Material:: | 38CrMoAlA,DC5,D2,SACM645,ect. |

| Bimetallic Screw Process:: | Spray Welding |

| Bimetallic Barrel Process:: | Centrifuge Casting |

| Bimetallic Depth:: | 2~4mm |

| Application:: | Double Screw Extruder |

| Service for Machine Brand:: | SJSZ,KMD,Weber,Cincinati,Battenfeld,ect. |

| Design 1:: | For High CaCo3 |

| Design 2:: | 50 % wood + 50% plastic |

| End products:: | WPC, profile, pipe film etc. |

| Certificates:: | GB/T19001-2008/ISO9001:2008/SGS |

| Production Capacity: | 1000 sets per month |

| Packing: | Wooden Case (Exported Standard) |

| Delivery Date: | 25 Days |

Product Description

SJSZ 65/132 conical screw barrel

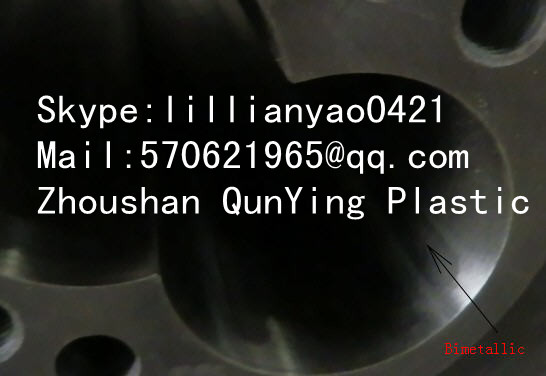

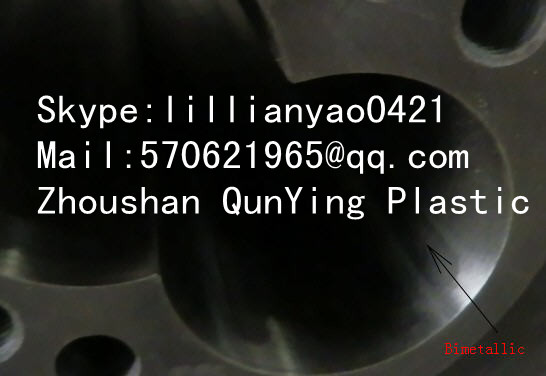

The picture you click is one type of our conical twin screw and barrel,SJSZ 65/132 conical barrel. And here is the 65/132 screws:

All our conical twin screws and barrels are with bimetallic on the ejection part. To ensure the quality.

SJSZ 65/132 conical barrel pictures again:

Bimetallic on barrel

Any question,or you want to order one set, you could send me mail on the picture.

And the following is the specification of conical twin screw and barrel we could produce.

The Specification of Conical twin screw and barrel

Technical Date ( Description)

Technical Date ( In detail)

Our Conical twin screw and barrel is good in quality and competitive in price. We manufacture Rubber screw barrel and supply OEM, ODM service according to your requirement.

Certificates:

The picture you click is one type of our conical twin screw and barrel,SJSZ 65/132 conical barrel. And here is the 65/132 screws:

All our conical twin screws and barrels are with bimetallic on the ejection part. To ensure the quality.

SJSZ 65/132 conical barrel pictures again:

Bimetallic on barrel

Any question,or you want to order one set, you could send me mail on the picture.

And the following is the specification of conical twin screw and barrel we could produce.

The Specification of Conical twin screw and barrel

Specification (d/D) | Work Length (mm) | Extruding Ability KG/H) | Screw Speed (rmp) |

Φ25/Φ53 | 540 | 25-40 | 5-50 |

Φ35/Ø77 | 810 | 40-70 | 5-50 |

Φ45/Φ90 | 990 | 50-80 | 5-45 |

Φ50/105 | 1070 | 100-150 | 4-45 |

Φ51/105 | 1220 | 100-150 | 4-40 |

Φ55/Φ110 | 1220 | 120-180 | 4-40 |

Φ60/Φ125 | 1320 | 150-200 | 4-40 |

Φ65/Φ120 | 1440 | 200-250 | 4-40 |

Φ65/Φ132 | 1440 | 200-250 | 4-40 |

Φ70/Φ140 | 1460 | 250-320 | 4-35 |

Φ75/Φ150 | 1480 | 300-360 | 4-35 |

Φ80/Φ143 | 1800 | 300-360 | 4-35 |

Φ80/Φ156 | 1660 | 300-360 | 4-35 |

Φ90/Φ184 | 2000 | 400-500 | 3-35 |

Technical Date ( Description)

Material | 38 38CrMoALA,SKD61,D2 etc. |

Hardness After Hardening&Tempering | HB260-290 |

Depth of Nitrided | 0.5-0.8mm |

Hardness of The Surface | Hv950-1100 |

Surface Roughness | Ra0.4um |

Linearity of Screw | 0.015mm/m |

Our Conical twin screw and barrel could serive high addtive of CaCo3 and wood.

The compression ratio of the screw canbe designed according to different products and mixtures.

If you have any inquiry, do not hesitate to inform us.

Conical twin screw barrel has been presented above, want more similar products, please click Conical twin screw barrel.

Technical Date ( In detail)

| Technical Parameter | |

Base Material | 1)38CrMoAlA(JIS SACM645);2)Cr12MOV(JIS SKD-11) ; 3)4Cr5MoSiV1(JIS SKD-61) ;4)42CrMo(AISI 4140) |

| Bimetallic Alloy Materials | 1)Fe-based alloy 2)Ni-based alloy/Deloro alloy 3)Co-based alloy 4)NiCo-based alloy 5)Tungsten carbide/Wolfram carbide |

| Double-alloy level | Level A - containing Tungsten of 40% Level B - containing tungsten of 25% Level C - containing tungsten of 15% |

| Surface Treatment | Heat Treatment High Frequency Treatment Nitriding treatment(120 Hours): Depth of Nitrided Layer: 0.5-0.8 mm Hardness of Nitrided Layer: 900-1020Hv (HRC56°-65°) Hard Chrome Plating treatment: Thickness of Hard Chrome Plating Layer: 0.05-0.10mm Hardness of Hard Chrome Plating Layer: ≥950HV Nickel alloy plating.treatment: Bimetallic Barrel/Cylinder: Centrifugal Casting (Inlay Alloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness of Bimetallic Layer: HRC55°-72° Spraying corrosion wear-resisting dual metal layers |

| Basic information | Roughness of the surface:Ra0.4um Linearity of the screw: ≤0.015mm Linear axis limit: ≤0.02mm Hardness after Hardening & Tempering: HB240-280 Fragility of Nitration:≤Two class |

| Material Application | 1)General Plastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA + GF(Glass Fiber) 4)Flame-resistant Reinforced Plastics 5)Modified Engineering Plastics 6)All kinds of Mixed Recycled Material(in Scrap or Granule), PVC + 30% CaCo3, etc |

Our Conical twin screw and barrel is good in quality and competitive in price. We manufacture Rubber screw barrel and supply OEM, ODM service according to your requirement.

Our factory processing pictures:

Certificates:

About QunYing

Zhoushan QunYing Plastic Machinery Co.,Ltd is a leading supplier of SCREW and BARREL in

China,including designing,manufacturing and sales for the products,we can make any specification of

extruder screw barrel and injection molding screw barrel for

Haitian,Demag,Engle,Nigrobossi,KMD,NPM,BOY,HUSKY, Nippon Steel, Toshiba, Nissei, Mitsubishi and etc. We also can supply SCREW&BARREL for blow mould machine,rubber machine and double screw barrel

machine and ect. Besides,we could design all types of screw and barrel according to your different

requirements.

Zhoushan QunYing Plastic Machinery Co.,Ltd is a leading supplier of SCREW and BARREL in

China,including designing,manufacturing and sales for the products,we can make any specification of

extruder screw barrel and injection molding screw barrel for

Haitian,Demag,Engle,Nigrobossi,KMD,NPM,BOY,HUSKY, Nippon Steel, Toshiba, Nissei, Mitsubishi and etc. We also can supply SCREW&BARREL for blow mould machine,rubber machine and double screw barrel

machine and ect. Besides,we could design all types of screw and barrel according to your different

requirements.

What is our SCREW and BARRELadvantage:

First:Creative in design,our designing team is very strong,since we have unique culture to motivate them,in order to meet requirement,we work closely to our customer and market!

Second:We have 15 years' experience of manufacturing varied screws, barrels and spares.We are keeping improving our production system day by day on the delivery, quality control,all the efforts have improved the customers satisfaction!

Third:We are located in China's screw Town-Jintang,Town in zhoushan city,near to Ningbo Port and Shanghai Port!

Finally,We assure the customer benefits,we supply best quality and competitive price,also best customer service!

At last,any enquiries,please contact us, also you could add my QQ:570621965.skype:lillianyao0421

My name is lillian.

My name is lillian.