bimtallic twin parallel screw barrel for pvc material zhoushan factory

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Nitrided Feed Screw Barrel, Extrusion Screw And Barrel, Bimetallic Screws And Barrel, Twin Screw And Cylinder, Parallel Twin Screw Barrel |

Product Detail

| Model No.: | QY-130325F |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Plastic Type: | PVC |

| Use: | Others |

| Shaft Design: | Double |

| Brand Name: | QunYing |

| Power: | 4-150KW |

| Base Material: | 38CrMoAlA,DC5,D2,SACM645,ect. |

| Bimetallic Screw Process: | Spray Welding |

| Bimetallic Barrel Process: | Centrifuge Casting |

| Nitrided layer depth: | 0.5-0.8mm |

| Surface roughness:: | Ra0.4um |

| Bimetallic: | Fe-based,Ni-based,Tungsten Carbide(Wc) |

| Application: | Proflie,PVC/PE/PP Granules/profiles/Foaming... |

| End products: | WPC, proflie, pipe film etc. |

| Desigh: | As BAUSANO/KraussMaffei/Cincinnati/Battenfeld... |

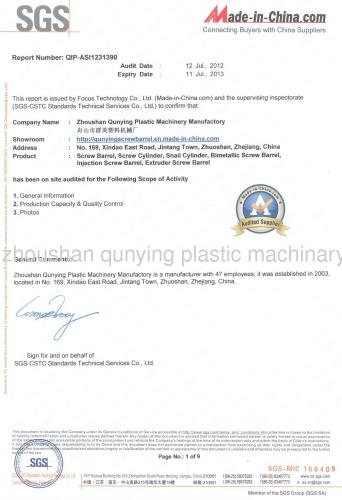

| Certificates: | GB/T19001-2008/ISO9001:2008/SGS |

| Production Capacity: | 1000 sets per month |

| Packing: | Wooden Case (Exported Standard) |

| Delivery Date: | 25 Days |

Product Description

Bimtallic twin paralle screw barrel for pvc material zhoushan factory :

1.Advanced Nitriding Technology

2.Anti-corrosion and Wear-resisting Duplex Metal Spraying Technoloy

3.We use special alloy powders being sprayed and welded on the screw's ridge,and

use different alloy and welding methods for the screw of different functions.

Especially application:

Rubber,various high glass fiber, mineral fiber and PPA,PPS, PA6T, LCP,VO fire protection, ferrous power, magnetic powder and etc. Meanwhile,Used for PVC + 30% CaCo3, recylced plastic material,etc. Diameter Φ15mm-Φ350mm Designing Screw structure and compression ratio can be designed according to different products & different output requirement. Materials 38CrMoAlA (JIS SACM645) SKD61 Application PVC plate, pipe, profile, pellet and mould, at the same time, it solved the technical problem of low foaming, high foaming, high filling, wear and corrosion. Nitride Case Depth 0.5mm-0.8mm Technology 1)Longer time Gas Nitriding treatment 2)special anti-wear & abrasion alloy (bimetallic) 3)tungsten carbide 4)cobalt base alloy 5)stainless steel 6)Gh113 nickel based alloy Nitride Hardness 950-1020HV Packing Wrapped up by film in wooden Nitride Brittleness ≤Grade One Payment Term T/T , L/C Surface Roughness Ra0.4um Delivery Term 25 working days Screw Straightness 0.015mm Port Departure Shanghai/Ningbo Alloy Hardness HRC58-62 Min. Order 1 set Alloy Depth 0.5mm-0.8mm Common Nitrided:2.5-4years Bimetallic: much longer lifetime. Guarantee

Certificates: