blow film machine screw barrel

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Nitrided Feed Screw Barrel, Extrusion Screw And Barrel, Bimetallic Screws And Barrel, Twin Screw And Cylinder, Parallel Twin Screw Barrel |

Product Detail

| Model No.: | QY-130316B |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Plastic Type: | PP/PE |

| Shaft Design: | Single |

| Brand Name: | QunYing |

| Power: | 4-150KW |

| Base Material: | 38CrMoAlA,DC5,D2,SACM645,ect. |

| Screw barrel Nitriding time: | More Than 120 Hours |

| Screw Barrel Bimetallic Thickness: | 2-4mm |

| Chromiun-plating Depth: | 0.15-0.2mm |

| Screw Barrel Hardness: | HRC 56-65 |

| Surface Roughness: | Ra0.4um |

| For What Machine Screw Barrel Work: | Blowing Moulding Machine |

| Plastic Material Application: | PP PE LDPE HDPE PMMA...ect. |

| Product Application: | Film,Bag,Bottle..ect |

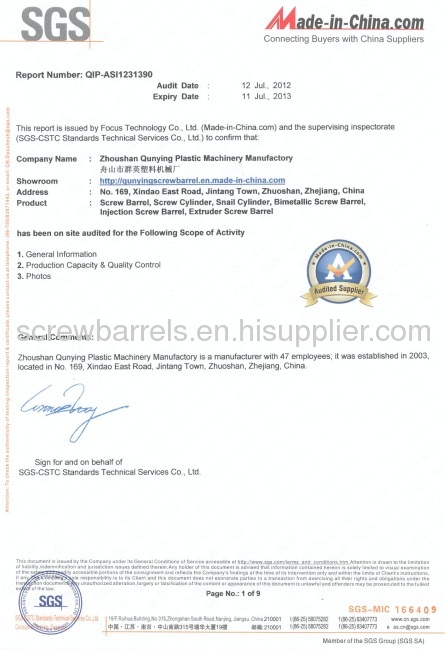

| Certificates: | GBT 19001-2008/ISO9001:2008/SGS |

| Production Capacity: | 1000 sets per month |

| Packing: | Wooden Case (Exported Standard) |

| Delivery Date: | 25 Days |

Product Description

blow film machine screw barrel

Diameter of single screw : D15mm~D300mm

L/D: 12~45

Max. Length: less than 10000mm

Scope of application: pipe, film, profile, sheet, pvc pe/pew pc pelleting etc.

For good plasticizing effect, we have different design of screw & barrel to meet your requirements

Screw Type:

Gradient-type, mutant, wave type, barrier type, dual type, shunt type, separate type, exhaust type, pin type, mixed type, double-headed type, three-type, long type, grain type.

Material

Commonly used material is 38crMoAIA(nitrogen treatment),it can be changed as per your requirements. According to different usage, the choose for alloy is different, some require for abrasion-resistant while some require for corrosion-resistant. For standard, we have Fe-based, Ni-based, W2C alloy, Tungsten alloy etc for choice

Materials & Processes

SKD61(H13) | 38CrMoAIA 41CrAMo7 |

Gr12MoV | High Quality Duplex Stainless Steel |

42CrMo | High Quality Powder Metallurgy Materials |

40Cr | Hard Metal Cold/Thermal Spraying Technology |

Zinc 3# Steel | Advanced Nitriding Technology |

Anti-corrosion and Wear-resisting Duplex Metal Spraying Technology | |

Screw structure and compression ratio can be designed according to different products and mixtures

Technical Parameter

Nitrided Case Depth | 0.5mm-0.8mm |

Nitrided Hardness | HV950-1020HV |

Nitride Brittleness | ≤Grade One |

Surface Roughness | Ra0.4um |

Screw Straightness | 0.015mm |

Alloy Hardness | HRC58-62 |

Alloy Depth | 0.5mm-0.8mm |

Chromium Coating Thicknss | 0.15~0.20mm |

blow film machine screw barrel

| Bimetallic Alloy Materials | 1)Fe-based alloy 2)Ni-based alloy/Deloro alloy 3)Co-based alloy 4)NiCo-based alloy 5)Tungsten carbide/Wolfram carbide |

| Double-alloy level | Level A - containing Tungsten of 40% Level B - containing tungsten of 25% Level C - containing tungsten of 9.5% |

Bimetallic screw: Base material 38CrMoAlA, sprayed alloy powder on the screw flight, prolong life of screw.

Bimetallic barrel: Base material 40Cr, casted a 2-5mm wear resistant and corrosion resistant bimetallic layer

on the barrel inner wall, so it has much longer using life than nitrided barrel.

We could design for you for any Genneral plastic materials(such as PP PE ABS AS PS PC PET PA PVC PMMA TPU PU etc.)and Enginneering plastic materials(such as ABS+PC BMC LCP PPS PAR PA-6 PA-66 PA9T PA4T CPVC PVDF POM Glass fiber etc.)

About Ours:

Our Certificates: