Poultry processing equipment water chilling machine (Halal)

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 200 SETS/YEAR |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Poultry Processing Machinery Bloodletting Line, Chicken Processing Plants Food Processing Equipment, Chicken Processing Equipment Mobile Type For 500 Bph Line, Chicken Farming Equipments Automatic Nipple Drinking Line, Food Processing Machine Slaughterhouse Equipment |

Product Detail

| Model No.: | LQJ-Ⅲ |

|---|---|

| Means of Transport: | Ocean |

| Processing Types: | Meat |

| Brand Name: | Toplea |

| Processing: | Pre-chilling |

| Material: | Stainless Steel |

| Colour: | Grey |

| Voltage: | 220V 380V |

| Diameter: | 1600/2100mm |

| Chilling Time: | 45 mins (customized) |

| Water capacity: | 6-31 ton |

| Condition: | New |

| Capacity: | 500-13500 bph |

| Production Capacity: | 200 SETS/YEAR |

| Packing: | Damp proof |

| Delivery Date: | 1-2 months |

Product Description

Product Description

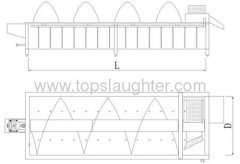

1. Toplea Chiller Machine is designed for cooling section before cup-up, to reduce the temperature of whole poultry or poultry parts by cooling water combined with agitation, within 45 mins.

2. Spin propelling system and blowing system make the cooling more even and thorough, to reach good aging effect.

3. Toplea Chiller can be supplied in customized size to match your production requirements.

Working Principle

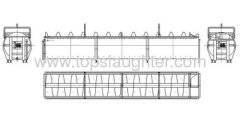

1. Sprial/Screw chiller is used in the water chilling process, which is divided into two parts. One is for washing and disinfection, while the other one is for chilling or cooling. The second chiller is larger than the first one;

2. Blower takes an important role in the chilling process, which is installed overhead chilling machine. It makes the cooling water into bubbles by some tubes from the bottom of the machine to blow into inner part. In this way, chilling water rollers repeatedly to ensure balanced water temperature, which benefits for producing qualitative finished products.

Working Step:

1. Poultry carcass drops into the first washing tank from the evisceration line after feet cutting process, where the water temperature is 10-16℃ and at this time chicken body's temperature is 36℃;

2. After 10 minutes' washing, the temperature of poultry carcass falls to 24℃;

3. Then poultry carcasses are transferred to the chilling unit, where chiller tank is longer than the first washer tank, but both of which have the same working principle. At this process, ice will be dropped down to the chilling tank from ice flaker and maker machine, installed on the overhead, to chill water temperature down to 0-4 °C;

4. After water chilling within 45 mins, the temperature of the carcass decreases significantly to below 6°C.

Product Features

Entirely made of stainless steel except gear motor, air pipe,air blower. Stainless steel height adjustable feet.

Supplied with air blowers and dial thermometers.

The electric motor for driving the shaft with variable frequency step-less speed regulation.

The machine cannot make cool water by itself, and our company can supply the high quality ice maker and flaker, whose main parts are made in Germany.

Working stable, high efficiency, easy operating and cleaning.

Specification

Specification | water(Ton) |

4000×1600×1900 | 6 |

6000×1600×1900 | 9 |

8000×1600×1900 | 12 |

10000×1600×1900 | 15 |

12000×1600×1900 | 18 |

6000×2100×2400 | 16 |

8000×2100×2400 | 21 |

10000×2100×2400 | 26 |

12000×2100×2400 | 31 |

Poultry processing equipment screw chiller

Poultry Processing Machine poultry/chicken carcass chiller

Poultry processing machinery pre-cooling machine

Chicken processing machine pre-cooler machine