Slaughter equipment sheep balanced pre dehiding automatic conveying line

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 300 sets/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Poultry Processing Machinery Bloodletting Line, Chicken Processing Plants Food Processing Equipment, Chicken Processing Equipment Mobile Type For 500 Bph Line, Chicken Farming Equipments Automatic Nipple Drinking Line, Food Processing Machine Slaughterhouse Equipment |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Processing Types: | Meat |

| Brand Name: | Toplea |

| Application: | Sheep Goat |

| Processing: | Pre-peeling/ pre-dehiding |

| Voltage: | 380v 220v |

| Condition: | New |

| Industry: | Meat processing machinery |

| Material: | Stainless steel |

| Type: | Livestock Slaughter Machine |

| Export Markets: | Global |

| Production Capacity: | 300 sets/year |

| Packing: | damp proof |

| Delivery Date: | 1-2 months |

Product Description

Sheep/ Goats Parallel Pre-dehiding automated conveyor line

Product profile

The sheep/goats parallel pre-dehiding conveying line is innovated technique, based on absorbing advanced technology. It has been successfully used for large and medium sheep slaughtering plants.

The goat's hind leg is hooked in the bloodletting /pre-peeling automatic conveyor line, at the same time, the foreleg is hooked by the shackle in the peeling auto-conveying line. The speed of these two lines is synchronous. Goat's belly is upturned and its back is down. The two lines are balanced forward and during the conveying, the skin pre-peeling will be finished. This way of pre-peeling can effectively avoid the sheep carcass sticked by wool during the pre-peeling procedure.

Product features

1. The whole set equipment is made of drive, tensioning device, drive chain and others, where tension device makes drive chain moving smoothly and stably by telescopic cylinder;

2. The balanced pre-peeling line and bleeding line are in step with each other;

3. Hindlimb cutting, head cutting and pre-peeling will be done in this section, where processed hindlimb and head are to be transported to the Carcass processing room;

4. It effectively sloves the problems caused in the manual hand pushing line, such as physical exertion and low working efficiency.

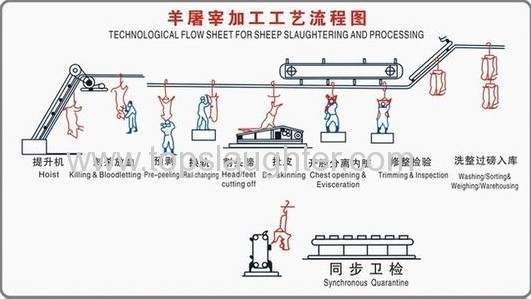

Technological flow sheet for sheep slaughtering and processing