Rendering Plant Wast Material of Slaughtering

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 300 sets/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Poultry Processing Machinery Bloodletting Line, Chicken Processing Plants Food Processing Equipment, Chicken Processing Equipment Mobile Type For 500 Bph Line, Chicken Farming Equipments Automatic Nipple Drinking Line, Food Processing Machine Slaughterhouse Equipment |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Type: | Food Waste Disposer |

| Brand Name: | Toplea |

| Application: | Fish Meal Plant, Animal or Poultry Rendering Plants |

| Eco-Friendly: | Yes |

| Energy Saving: | Yes |

| Condition: | New |

| Belt Conveyor: | SUS304 |

| Waste Gas Treatment (i): | Vacuum Drying Equipment |

| Waste Gas Treatment (ii): | Horizontal Condenser |

| Cooling Tower: | fiberglass |

| Residual Gas: | Spray tower |

| Deodorization: | Biological agent (Natureally non-toxic) |

| Production Capacity: | 300 sets/year |

| Packing: | damp proof |

| Delivery Date: | 1-2 months |

Product Description

Company Introduction

Our co-operate company, awarded "China Drying Equipment Industry Excellent Enterprise", has gathered more than 20 years in the field of waste treatment and management, and has gradually developed into an integrated enterprise with research & development, manufacture, installation & debugging, specialized in manufacturing rendering equipment for processing waste from slaughtering for poultry, livestock, fish and etc. Rendering Equipment focuses on help our customers treat with slaughterhouse waste eco-friendly and gain the increased profit from the finished product such as feather meal, meat and bone meal, blood meal, fish meal and so on .

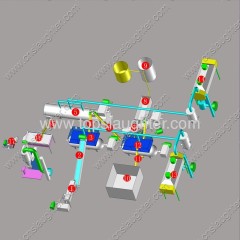

I. 3D Flow Chart of Fish Meal Plant

1) Raw material crusher

2),4),8),10),12)Spiral conveyor

3) Cooker

5) Double-shaft squeezing machine

6) Centrifuge

7)Oil storage tank

9),11)Steam dryer

13) Rotary cooler

14),15)Cooler

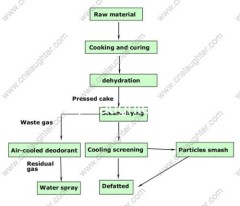

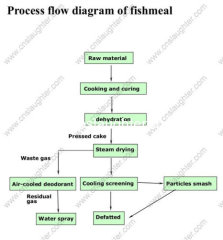

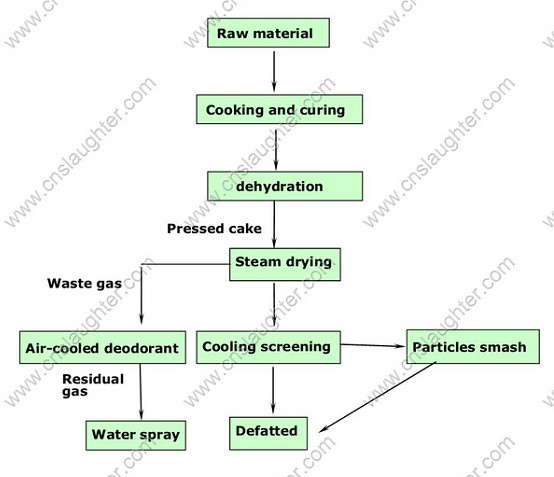

Process flow diagram of fishmeal

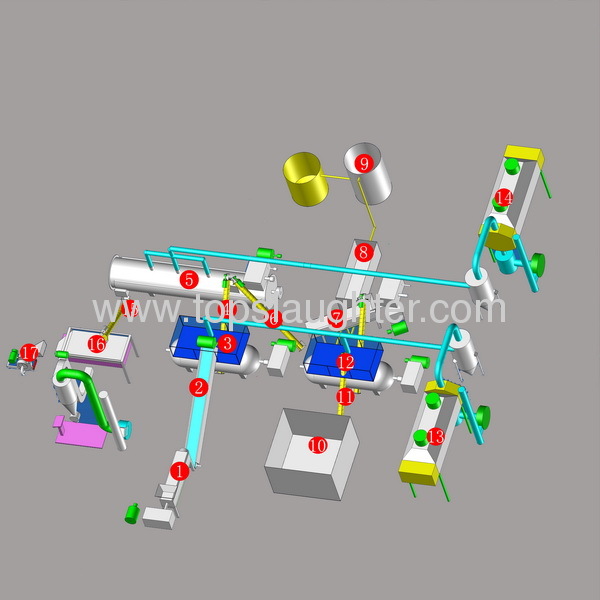

II. 3D flowchart For Poultry Rendering Plant

1) Feather dehydration

2) Belt conveyor

3),12)Cooker

4),6), 11),15)Spiral conveyor

5) Steam dryer

7)Double-shaft squeezing machine

8)Grease precipitation tank

9)Oil separator

10)Blood storage tank

13),14)Cooler

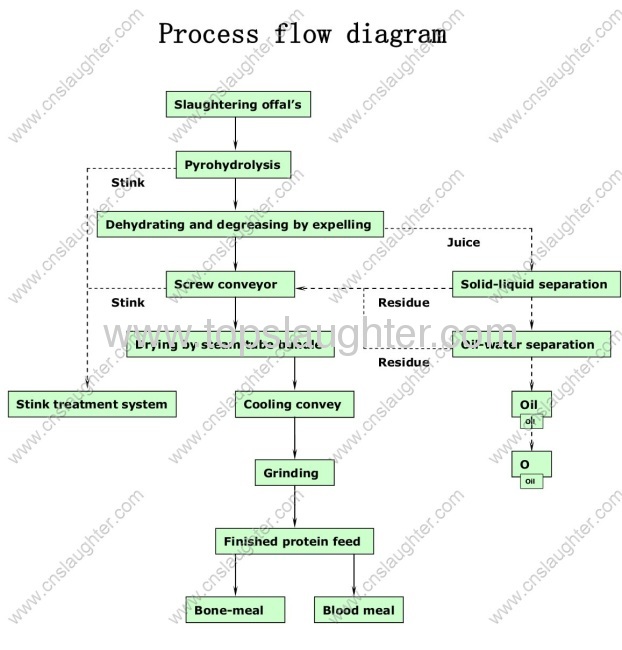

Process Flow Diagram of Slaughtering Offals

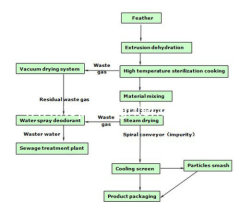

III. 3D Flow Chart of Feather Meal Plant

Process Flow Diagram of Feather Meal