rendering plant waste gas treatment system

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 300 sets/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Poultry Processing Machinery Bloodletting Line, Chicken Processing Plants Food Processing Equipment, Chicken Processing Equipment Mobile Type For 500 Bph Line, Chicken Farming Equipments Automatic Nipple Drinking Line, Food Processing Machine Slaughterhouse Equipment |

Product Detail

| Model No.: | φ1000x3500 |

|---|---|

| Means of Transport: | Ocean |

| Type: | Food Waste Disposer |

| Brand Name: | Toplea |

| Application: | Fish meal, Feather powder units |

| Material: | Stainless Steel |

| Draft fan: | Y6-41 NO4.8 |

| Dimension: | 1000X1000X3000mm |

| Pump: | P=3kw |

| SUS304 stainless steel: | δ=3mm |

| Spray head: | Increae contact area |

| Industry: | Poultry rendering plants Odor treatment |

| Production Capacity: | 300 sets/year |

| Packing: | damp proof |

| Delivery Date: | 1-2 months |

Product Description

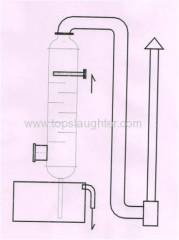

Equipment components:

1) Catcher 2) Spray tower 3) Stainless steel induced draft fan Y6-41 NO4.8 4) Centrifugal pump

Process Description:

a) Emissions are generated in the production process through the fan negative pressure drainage. From the exhaust port into the set to catch, and then into the spray tower cooling, the exhaust gas condenses into water to collect emissions, and then goes into the waste gas treatment system.

b) Gas into the spray tower starts the centrifugal pump, supporting the nozzle of the spray tower. Spray deodorant, in a full contact with the waste steam achieves the best effect.

Process Principle

1. Waste gas processing system use vacuum drying and cooling equipment, turning waste gas into the water, which can reduce water waste and save resources.

2. The residual gas then processed by water spray reaches zero emission standard.

3. Equipped with cooling tower to cool hot water for recycling.

Waste gas treatment system

Spraying Tower for the Odor Treatment process

Waste gas treatment system