Rendering plants Feather recycling machine steam dryer

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 300 sets/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Poultry Processing Machinery Bloodletting Line, Chicken Processing Plants Food Processing Equipment, Chicken Processing Equipment Mobile Type For 500 Bph Line, Chicken Farming Equipments Automatic Nipple Drinking Line, Food Processing Machine Slaughterhouse Equipment |

Product Detail

| Model No.: | HG-1200 1300 1400 1500 |

|---|---|

| Means of Transport: | Ocean |

| Type: | Others |

| Brand Name: | Toplea |

| Heat efficiency rate: | 95% |

| Specification: | 5500*1500*2200mm |

| Main Shaft: | Φ377×20 Seamless steel tube |

| Inner Cylinder: | 16MnR |

| Insulation: | Aluminum silicate |

| Working pressure: | 0.7MPa(164℃) |

| Outer case: | SUS304 stainless steel material |

| Outer jacket: | Q235B carbon steel |

| Reducer: | ZLY280 |

| Power: | 22KW |

| Production Capacity: | 300 sets/year |

| Packing: | Moisture Proof |

| Delivery Date: | 1-2 months |

Product Description

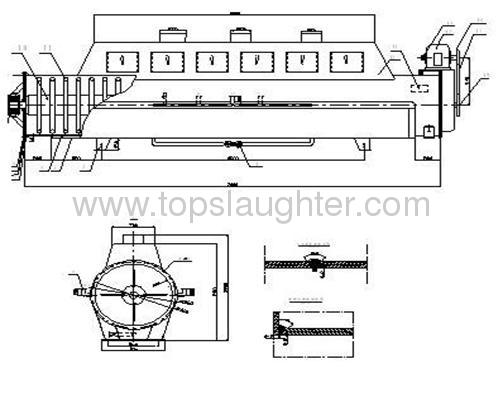

Equipment components:

Rotary Joints, Stainless steel hose, Sealing ring, Cut-off valve, Safety valve, Float type trap, Pressure gauge, Bearing, Triangle

Performance and characteristics:

1. Transfer steam through outer jacket, main shaft or steam box to increase the heating area and make the heat efficiency reach up to 95%, to ensure that the material is fully dried.

2. The exhaust hood and pipelines are made of stainless steel to improve corrosion resistance and extend service life.

3. Use automatic water conveyor system to recycle Steam condensate water to the boiler, so that it can reduce energy consumption and save water.

4. The blades keep stirring to slove the problem of sticky materials and make the material heated uniformly.

5. Clients need to buy steam boiler to equip with steam drier working. Toplea can also supply the high quality steam boiler to every client.

Technique Parameter

Specification: 7800X1500X2200mm

Power: P=37kw

1. Main shaft made of Φ377×20 Seamless steel tube, Q235B, full of steam to enhance heat exchange area | 2. Dryer inner cylinder use 16MnR, thickness δ=16mm,outer jacket use Q235B carbon steel, thicknessδ=12mm | 3. Insulation: use aluminum silicate, insulation board made of Stainless steel SUS430,thickness δ=0.7mm; |

4. Outer case use SUS304 stainless steel material, δ=2.5mm | 5. Bearing: double row self-aligning Bearing 3526, thrust bearing 8326; | 6. Draining device : equipped with rotating joints and stainless steel hose DN50, to discharge condensation water from main shaft and jacket |

7. Steam: working pressure 0.7MPa (164℃) | 8. Air consumption: 1100kg/h; | 9. Reducer use ZLY280 unit |

Device parameters:

Model | HG-1200 | HG-1300 | HG-1400 | HG-1500 |

Production | 0.6t/h | 0.8t/h | 1.0t/h | 1.2t/h |

Total power | 18.5kw | 22kw | 30kw | 37kw |

Inner cylinder diameter | Φ1200 | Φ1300 | Φ1400 | Φ1500 |

Reducer power | ZLY224 | ZLY250 | ZLY280 | ZLY315 |

Weight | 7500kg | 8600kg | 9800kg | 11000kg |

Rendering Plants Steam dryer

Rendering Equipment Steam Dryer

Poultry Rendering Plants Steam Dryer