Abattoir equipment spiral chiller

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 200sets/ year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Poultry Processing Machinery Bloodletting Line, Chicken Processing Plants Food Processing Equipment, Chicken Processing Equipment Mobile Type For 500 Bph Line, Chicken Farming Equipments Automatic Nipple Drinking Line, Food Processing Machine Slaughterhouse Equipment |

Product Detail

| Model No.: | LQJ-Ⅲ |

|---|---|

| Means of Transport: | Ocean |

| Processing Types: | Meat |

| Brand Name: | Toplea |

| Voltage: | 220v/380V |

| Processing: | chilling pre-cooling |

| Colour: | Grey |

| Material: | Stainless steel |

| Chilling bath diameter: | 2100mm |

| Application: | Poultry |

| Condition: | New |

| Industry: | Meat Processing Machinery |

| Pre-Chilling time: | 45 mins (customized) |

| Chilling Temp: | 0-4C |

| Production Capacity: | 200sets/ year |

| Packing: | Seaworthy Packing |

| Delivery Date: | 1-2 monts |

Product Description

Chicken processing equipment chilling machine

Super spiral chiller is used for poultry slaughterhouse pre-cooling section to cool the poultry carcass. This equipment needs more water than usual chiller, but efficiency will improve several times. It needs an ice maker and flaker installed on the body rack to get the ice for lowering the inside water temperature. Then the chicken's feet will be cut by feet cutting machine on the suspension line, and carcass will be dropping on the chiller. At last chicken will be pushed forward by the spiral blade from inlet to outlet .

Customers can choose super spiral chiller or the air chilling line for cooling the chicken carcass. For super spiral chilling machine, it must be equipped with the condenser or ice maker and flaker. Our company supplys the high quality ice maker and flaker, the main part is made in Germany. In case of choosing air cooling line, it should be equipped with the refrigeration unit (compressor, fan and others).

REMARK:

Spiral chiller itself is applied only to move the chicken from the inlet of the chiller to the outlet by the spiral shaft and ejector. This machine can not provide cool water by itself. Usually it works with ice maker or machine unit that can make cool water.

Air chilling consists of one overhead chain conveyor and one set of refrigerating unit.

THE MAIN FEATURES:

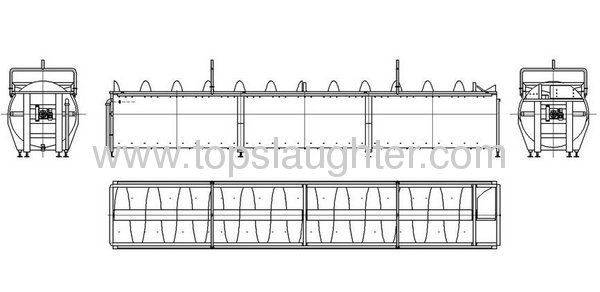

Stainless steel structure, stainless steel water tank and spiral shaft(δ=3.0mm).

Supplied with air transport system (TAIWAN brand vortex pump).

More water holding, more space-saving.

Two gear motor driven.

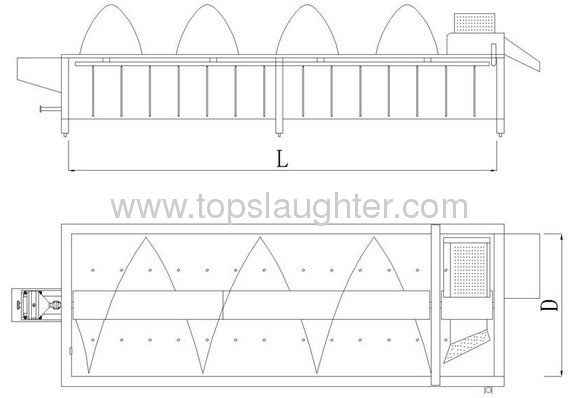

SPECIFICATION:

| Model | Dia.(mm) | Specification | water(Ton) |

| LQJ-Ⅲ | 1600 | 4000×1600×1900 | 6 |

| 6000×1600×1900 | 9 | ||

| 8000×1600×1900 | 12 | ||

| 10000×1600×1900 | 15 | ||

| 12000×1600×1900 | 18 | ||

| 2100 | 6000×2100×2400 | 16 | |

| 8000×2100×2400 | 21 | ||

| 10000×2100×2400 | 26 | ||

| 12000×2100×2400 | 31 |

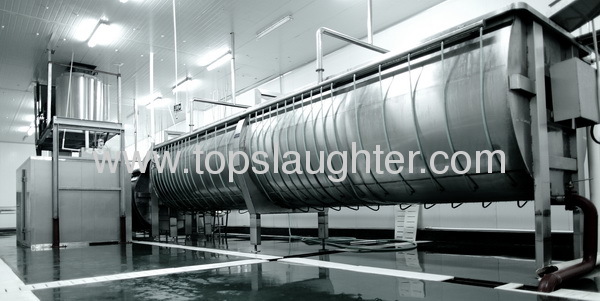

PRODUCT PICTURE:

Chicken slaughter house equipment: chiller

Poultry Processing Machine Pre-chiller/chilling Machine

Poultry Processing Equipment Pre-cooling Machine/Pre Cooler Machine

Poultry house equipment: chiller