HDPE pipe extrusion line

75000.0~77500.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 50 sets one year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Plastic Machine |

Product Detail

| Model No.: | HDPE-200 |

|---|---|

| Means of Transport: | Ocean |

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | PRECISION |

| Power: | 160kw |

| Pipe range: | 75-200mm |

| Extruder: | SJ-75/33 |

| Center high: | 1000mm |

| Overall diamension(L*W*H): | 36m*2.5m*3m |

| Weight: | 10 T |

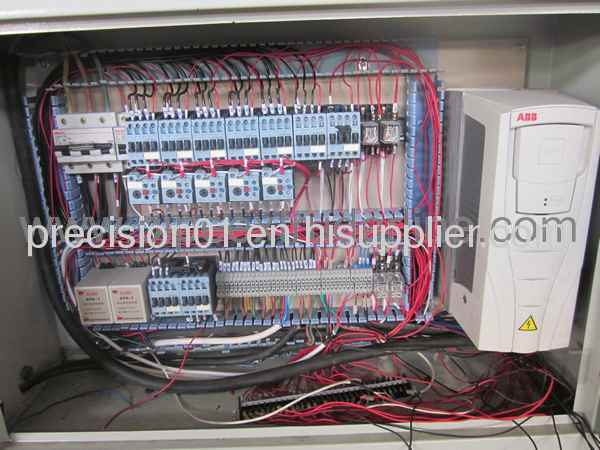

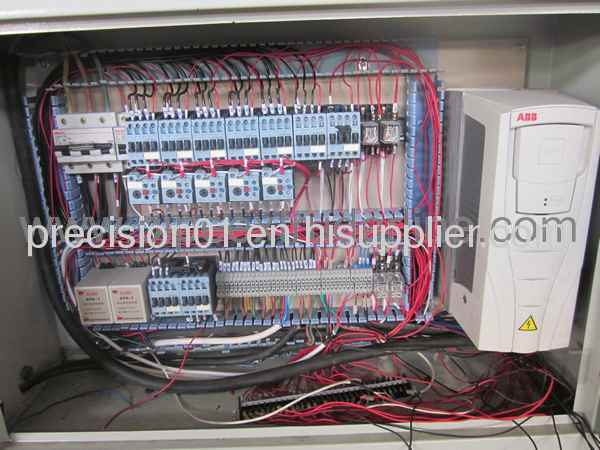

| Main electrical applicance: | ABB,Siemens,Moron |

| Control system: | PLC automatic control |

| Certificates: | PLC automatic control |

| Total installed power: | 160 kw |

| Actual power: | 100 kw |

| Production Capacity: | 50 sets one year |

| Packing: | wodden case or customize |

| Delivery Date: | 30 working days after receive 40% deposit |

Product Description

Automatic feeding and drying machine: It has a good effect for the powder and granule .

Single screw extruder: The screw using for the BM type ,high output, best plastic and stabilization.

Electrical system: Siemens PLC, ABB converter, Omron temperature controller. The entire production line adopts the originally imported new control system of PLC programmable computer, guaranteed highly and steadily reliable controls of the production line.

Marking line extruder: The extruder can be used for extruding thermo-plastics as PVC,PP, PE, PP-R, ABS. And this extruder can be used for different color mark line, for example:blue mark line, red mark line, er...

Die head: Die headsof helical type and basket type are perfect for polyolefin, and can help to produce sound melting pressure, and improve the plasticization capacity. Meanwhile, stable material-flow and pressure grade can be guaranteed.

Vacuum calibration tank: Advanced vacuum calibrating method improves the cleanliness and hardness of surface. Reasonable high-speed spray cooling water trough guarantees the pipe quality and high speed stable extruding.

Spraying water yank: Intensive cooling of the pipe thanks to optimized positioning of the bayonet-type spray nozzles. Baths and outer pipe work made from stainless steel

Printer: This device adopts stainless steel case and closed keyboard which make the whole machine water proof and dust proof. There is Clock system inside the device which can make the date and time printing in real time.

Haul-off machine: The hauling machine adopts anti abrasion alloy material, which realizes stable traction, wide frequency adjustment range and long lifespan.

Cutting machine: New generation auto dust-free cutting blade realizes smooth cutting secant, high precision and low noise.

Tilter: we can produce according to customer requirement.

.gif)