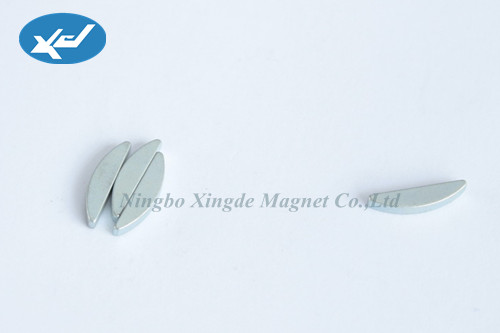

special shaped Sintered NdFeB magnets strong magnet permanent magnet

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, PAYPAL, T/T |

| Supply Ability: | 100ton/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Arc Motor NdFeB Magnet, Rare Earth Permanent Arc Magnet, Good Quality NdFeB Magnets, Rare Earth Permanent Magnets, N50 Permanent Ring Magnet BrmT(KG) 1400-1450(14.0-14.5) |

Product Detail

| Means of Transport: | international express, Ocean, Air, Land |

|---|---|

| Application: | Industrial Magnet |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Brand Name: | Xingde |

| Grade: | N, M, H, SH, UH, EH |

| Shape: | special |

| Coating: | Znic |

| Usage: | electronics, machines, etc |

| Production Capacity: | 100ton/year |

| Packing: | normal packing or as request |

| Delivery Date: | within 15 days |

Product Description

1, Descriptiom of Special shaped sintered NdFeB magnets.

(1) Shape: As request.

(2) Coating: Zn,Ni,Expoxy,NiCuNi Etc.

(3) Grade: N, H, M, SH, UH, EH.

(4) Regular Packing: magnetic power shield package or according to you.

(5) Usage: Industry, machines, electronics, etc.

2, Performance for Special shaped sintered NdFeB magnets.

Material Code | Br | Hcj | BH(max) | Max Working temperature | ||||

KGs | T | Koe | KA/m | MGOe | KJ/m3 | (Tw) | ||

N52 | 1430-1480 | 14.3-14.8 | >=11 | >=876 | 50-53 | 398-422 | 80℃ | |

N50 | 1400-1450 | 14.0-14.5 | >=11 | >=876 | 48-51 | 398-423 | 80℃ | |

N48 | 1380-1420 | 13.8-14.2 | >=12 | >=955 | 46-49 | 366-390 | 80℃ | |

N45 | 1320-1380 | 13.2-13.8 | >=12 | >=955 | 43-46 | 342-366 | 80℃ | |

N42 | 1280-1320 | 12.8-13.2 | >=12 | >=955 | 40-43 | 318-342 | 80℃ | |

N40 | 1250-1280 | 12.5-12.8 | >=12 | >=955 | 38-41 | 302-326 | 80℃ | |

N38 | 1220-1250 | 12.2-12.5 | >=12 | >=955 | 36-39 | 287-310 | 80℃ | |

N35 | 1170-1220 | 11.7-12.2 | >=12 | >=955 | 33-36 | 263-287 | 80℃ | |

50M | 1400-1450 | 14.0-14.5 | >=14 | >=1114 | 48-51 | 382-406 | 100℃ | |

48M | 1360-1430 | 13.6-14.3 | >=14 | >=1114 | 46-49 | 366-390 | 100℃ | |

45M | 1320-1380 | 13.2-13.8 | >=14 | >=1114 | 43-46 | 342-366 | 100℃ | |

42M | 1280-1320 | 12.8-13.2 | >=14 | >=1114 | 40-43 | 318-342 | 100℃ | |

40M | 1250-1280 | 12.5-12.8 | >=14 | >=1114 | 38-41 | 302-326 | 100℃ | |

38M | 1220-1250 | 12.2-12.5 | >=14 | >=1114 | 36-39 | 287-310 | 100℃ | |

35M | 1170-1220 | 11.7-12.2 | >=14 | >=1114 | 33-36 | 263-287 | 100℃ | |

33M | 1130-1170 | 11.3-11.7 | >=14 | >=1114 | 31-33 | 247-263 | 100℃ | |

30M | 1080-1130 | 10.8-11.3 | >=14 | >=1114 | 28-31 | 223-247 | 100℃ | |

48H | 1370-1430 | 13.7-14.3 | >=17 | >=1353 | 46-49 | 366-390 | 120℃ | |

45H | 1320-1380 | 13.2-13.8 | >=17 | >=1353 | 43-46 | 342-366 | 120℃ | |

42H | 1280-1320 | 12.8-13.2 | >=17 | >=1353 | 40-43 | 318-342 | 120℃ | |

40H | 1250-1280 | 12.5-12.8 | >=17 | >=1353 | 38-41 | 302-326 | 120℃ | |

38H | 1220-1250 | 12.2-12.5 | >=17 | >=1353 | 36-39 | 287-310 | 120℃ | |

35H | 1170-1220 | 11.7-12.2 | >=17 | >=1353 | 33-36 | 263-287 | 120℃ | |

33H | 1130-1170 | 11.3-11.7 | >=17 | >=1353 | 31-34 | 247-271 | 120℃ | |

30H | 1080-1130 | 10.8-11.3 | >=17 | >=1353 | 28-31 | 223-247 | 120℃ | |

45SH | 1320-1380 | 13.2-13.8 | >=20 | >=1592 | 43-46 | 342-366 | 150℃ | |

42SH | 1280-1320 | 12.8-13.2 | >=20 | >=1592 | 40-43 | 318-342 | 150℃ | |

40SH | 1240-1280 | 12.5-12.8 | >=20 | >=1592 | 38-41 | 302-326 | 150℃ | |

38SH | 1220-1250 | 12.2-12.5 | >=20 | >=1592 | 36-39 | 287-310 | 150℃ | |

35SH | 1170-1220 | 11.7-12.2 | >=20 | >=1592 | 33-36 | 263-287 | 150℃ | |

33SH | 1130-1170 | 11.3-11.7 | >=20 | >=1592 | 31-34 | 247-271 | 150℃ | |

30SH | 1080-1130 | 10.8-11.3 | >=20 | >=1592 | 28-31 | 223-247 | 150℃ | |

40UH | 1240-1280 | 12.5-12.8 | >=25 | >=1990 | 38-41 | 302-326 | 180℃ | |

38UH | 1220-1250 | 12.2-12.5 | >=25 | >=1990 | 36-39 | 287-310 | 180℃ | |

35UH | 1180-1220 | 11.8-12.2 | >=25 | >=1990 | 33-36 | 263-287 | 180℃ | |

33UH | 1130-1170 | 11.3-11.7 | >=25 | >=1990 | 31-34 | 247-271 | 180℃ | |

30UH | 1080-1130 | 10.8-11.3 | >=25 | >=1990 | 28-31 | 223-247 | 180℃ | |

28UH | 1020-1080 | 10.2-10.8 | >=25 | >=1990 | 26-29 | 207-231 | 180℃ | |

38EH | 1220-1250 | 12.2-12.5 | >=30 | >=2388 | 36-39 | 287-310 | 200℃ | |

35EH | 1170-1220 | 11.7-12.2 | >=30 | >=2388 | 33-36 | 263-287 | 200℃ | |

33EH | 1130-1170 | 11.3-11.7 | >=30 | >=2388 | 31-34 | 247-271 | 200℃ | |

30EH | 1080-1130 | 10.8-11.3 | >=30 | >=2388 | 28-31 | 223-247 | 200℃ | |

28EH | 1040-1090 | 10.4-10.9 | >=30 | >=2388 | 26-29 | 207-231 | 200℃ | |

3, Picture for Special shaped Sintered NdFeB magnets.

NdFeB, the third generation of rare-earth permanent magnet, not only owns the high remanence, high corrective force, high-energy products and high cost performance ratio, but can be easily fromed into various shapes and sizes. Avoiding the surface of the magnet being oxidized, ensuring the design of the products and its corrosion resistance to be widely applied in different conditions, it will be coated with Ni-Cu-Ni, Zn, Epoxy, passivated and decorated with plated Au, Ag, Cr. NdFeB magnetic products are widely used in several fields such as aviation, electronics, instruments, meters, machine, medical instrument, etc. Besides, it is especially suitable for the development of high performance, compact and light products.