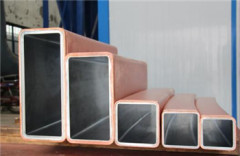

rectangle mould tube china

| Payment Terms: | L/C, T/T |

|---|---|

| Place of Origin: | Liaoning |

Company Profile

| Location: | Dalian, Liaoning, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | CCM Mould, Mould Tube, Copper Mould, Copper Pipe For Ccm., CCM Mould Tube |

Product Detail

| Model No.: | rectangle mould tube |

|---|---|

| Brand Name: | ZhengHe |

Product Description

Rectangle mould tube , The production of mould tubes starts with the casting of the selected alloy, which is then cast in bars with round cross section. The bars are then extruded and forged.

The tube thus obtained is cold-drawn, bent and tapered in a high-powered press. This last processing stage is by far the most crucial step in manufacturing mould tubes. To achieve it, special equipment is used which is specific to each type of ingot mould. The equipment itself is produced with sophisticated machinery.

Finally, the tubes under goes machining and is then chromium-plated internally, before being inspected and measured.

The size test certificate and the taper progression graph are packaged together with the material for delivery. Materials MM1, MM2, MM3, MM8 Cross section Square, rectangular, round, polygonal, beam blank Size Up to 750 mm (across), larger sizes available on request Internal profile Parallel, single CONE -shaped, multi CONE -shaped, parabolic, special parabolic Curving Straight, curved Radius of the inside corner > 1 mm Lengh Unlimited Wall thickness Unlimited Coating Chromium-plated, max. thickness 0.2 mm

D.Z.H.-the most professional and reliable supplier of copper mould tube for continuous casting machine which has exported copper mould tubes for 10 years.

copper mould tube manufacturers, copper mould tube suppliers, China copper mould tube, D.Z.H.