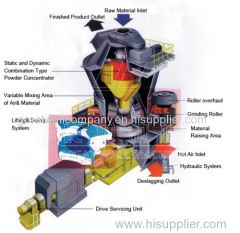

oriental Vertical Roller Mill

| Min. Order: | 1 Set/Sets |

|---|---|

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Jaw Crusher, Cone Crusher, Impact Crusher, Vertical Impact Crusher, Hammer Crusher |

Product Detail

| Packing: | special package |

|---|

Product Description

Vertical Roller Mill machine, which is developed and launched by Oriental, sets medium crushing, drying, grinding, classifying and other functions as a whole, being the ideal equipment in the grinding industry.

Features of Vertical Roller Mill

Application

Vertical Roller Mill is mainly applied in the grinding process of metallurgy, building materials, chemical, mining and other mineral industries, and suitable for grinding quartz, feldspar, calcite, talcum, barite, fluorite, rare earth, marble, ceramic, bauxite, manganese ore, iron ore, copper ore, phosphate rock, red iron oxide, zircon sand, slag, cement clinker, activated carbon, dolomite, granite, garnet, iron oxide yellow, chemical fertilizer, compound fertilizer, fly ash, bituminous coal, coking coal, lignite, magnesite sand, chrome oxide green, gold, red mud, clay, kaolin, coke, coal gangue, porcelain clay, kyanite, fluorspar, bentonite, rhyolite, pyrophyllite, shale, purple stone, Diego rock, basalt, gypsum, graphite, silicon carbide, thermal insulation materials and other non-flammable burst materials whose Mohs hardness are below 9.3.

Features & Advantages

Low running costs

It adopts the technology that vertical roller grind material directly on the disc, with low energy consumption; for the roller is not contact with the disc directly in the work, and the roller and liner are made by quality materials, it is of less wear and long life.

Simple and reliable operation

Its automatic control system can reach remote control, which is easy to operate; there is the device to prevent roller sleeve contact with disc liner directly, and avoid the destructive impact and severe vibration; we can turn the rotating arm by repairing fuel tank, replace the roller and liner are more convenient, which can reduce the downtime.

Energy conservation and environmental protection

It features small vibration, low noise, and sealing device as a whole, and the system also works with no pressure and dust spills.

Vertical Roller Mill PK Ball Mill

Reduce infrastructure investment:

The construction area is ??70% of ball mill and building space is 50-60%.

Smaller energy consumption:

Compared with ball mill, Vertical Roller Mill can reduce energy consumption 30% to 40%.

Low metal loss:

The metal loss of ball mill is great, there are about 500g metal impurities in per ton limestone; and the Vertical Roller Mill machine has only 5 ~ 10g metal loss. In this way, using the Vertical Roller Mill not only can reduce the metal loss up to 95%, but also reduce the influence of metal impurities on whiteness and purity of the finished product.

More environmentally friendly:

Vertical Roller Mill is of little dust and noise, which is about 80dB or so, the noise of ball mill is higher 20 ~ 30dB.

High degree of homogenization:

The products of Vertical Roller Mill have no over-crushed phenomenon. However, ball mill can result in over-crushed phenomenon easily, and its product size is very uneven.

Large drying capacity:

Vertical Roller Mill adopts hot gas to transport material, when grinding materials contain much water (such as coal, slag, etc.), it can control the inlet air temperature, until products reach the final moisture. Vertical Roller Mill can dry 12-15% of the moisture of material; and even the dry ball mill can only drying 3-4% of the moisture of material.