C&C Exquisite borosilicate mouth blown double wall glass cups for wine drinking

| Min. Order: | 2000 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 50000pcs/month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Glass Teapot/coffee Pot, Glass Mugs/cups, Glass Bongs, Glass Pipes/bubblers |

Product Detail

| Model No.: | WG024 |

|---|---|

| Means of Transport: | Ocean, Land |

| Height: | 15cm |

| Style: | Double Wall |

| Material: | Glass |

| Capacity: | Others |

| Usage: | Wine |

| Brand Name: | C&C Glass |

| hand blown craftsmanship: | enjoyable hand touch feeling |

| high Borosilicate glass: | Double wall wine glass |

| easy to clean ,less pollution: | artistic shape creates wonderful feeling |

| Eco-friendly Products: | Elegant and Innovative Design |

| Production Capacity: | 50000pcs/month |

| Packing: | carton |

| Delivery Date: | 15-255 days after receiving the advaned payment |

Product Description

Double wall glass introduction

Thank you for purchase of the high quality C&C brand borosilicate glass double wall insulated beverage glassware,which is made according to the highest standards in quality and durability.

All pieces of C&C brand double wall borosilicate glass insulated beverage glassware is made from borosilicate glass in double wall structure.While preventing you from burning your hands when filled with hot beverages and eliminating sweats on the outside when filled with cold drinks,it keeps your beverage hot and cold for a longer duration than traditional glassware in single wall structure.

Borosilicate glass is a special type of glass renowned for its superior resistance to chemical corrosion,heat,thermal shock and scratches.In addition,it is much lighter in weight but more solid in structure and so more durable than traditional soda lime glass.Thus,C&C brand borosilicate glass double wall insulated beverage glassware weighs so light even in double wall structure and remains durable even with the two layers of thin walls.Due to the properties of borosilicate glass,the glassware remains clear throughout its life span.

It's unique material choosen :borosilicate glass 3.3

Borosilicate glass is a type of glass with the main glass-forming constituents silica and boron oxide. Borosilicate glasses are known for having very low coefficients of thermal expansion(~3 × 10−6 /°C at 20°C), making them resistant to thermal shock, more so than any other common glass.

In addition to the quartz, sodium carbonate, and aluminum oxide traditionally used in glassmaking, boron is used in the manufacture of borosilicate glass. The composition of low expansion borosilicate glass such as those laboratory glasses mentioned above is approximately 80% silica, 13% boric oxide, 4% sodium oxide, and 2-3% aluminum oxide. Though more difficult to make than traditional glass due to the high melting temperature required, it is economical to produce. Its superior durability, chemical and heat resistance finds excellent use in chemical laboratory equipment, cookware, lighting and, in certain cases, windows.

Borosilicate Glassware Features and Advantages

1,they are heat resistant,suitable for use in microwave,dishwasher and stove

2,offer a variety of application possibilities: baking and cooking, preparing and serving, cooling and freezing (down to -35°C/-31°F)

3.show a high resistance to sudden temperature changes with a temperature difference of 140°C/284°F(three times as high as normal glass or lead crystal glass)

4,are produced from clear borosilicate glass which is free of smell and flavor,does not discolor and show high chemical and mechanical resistance

5,do not give off any substances and therefore are suitable for allergy sufferers

6,are easy to clean and hygienic in use through the pore-free surface

7,come in superior and functional product design for an optimal preparation of beverage and meal

8,are most suitable as an individual and creative gift idea

It's exquisite craftsmanship:pure hand made

1.Selecting high quality borosilicate glass tube 3.3

2.Stretching/Drawing the glass tube----To select glass tube according to products' overall

requirements,then melting,drawing and cutting the tube

3.Blowing----Blow the finished raw material to shape the glass tube embryo

4.Cracking off---To melt the shaped tube embryo,and drop extra raw material,then we have the

glass tube embryo mouth

5Special Crafts for Double wall glasses----Combining the double layers while rotating the glasses

with high temperature melting

Bonding ----To melt the embryo with extremely high temperature,then connect related glass parts

with glass embryo,thus we have a complete one

6.Sealing the Bottom---To melt and drop extra raw material,then flat the bottom

7.Logo Printing and Tempering---Print the logo onto the glasses,and put it into the electric stove

with temperature up to 580°C to 600°C,so that we could get rid of the stress from glasses

It's acknowaged quality standard

Present market Glasswares Grades

Top Quality High borosilicate glass: is approximately 80% silica, 13% boric oxide, 4% sodium oxide, and 2-3% aluminum oxide. It show high resistance to sudden temperature changes with a temperature difference of 170°C(-20°C---150°C)

Recycled borosilicate glass: with less than 20% silica,and contaminated to environment and human body

Normal Glass:contains too many complicated impurities and with machine mass production

C&C Glass products are all made of top quality high borosilicate glass,with superior heat resistant and eco-friendly quality

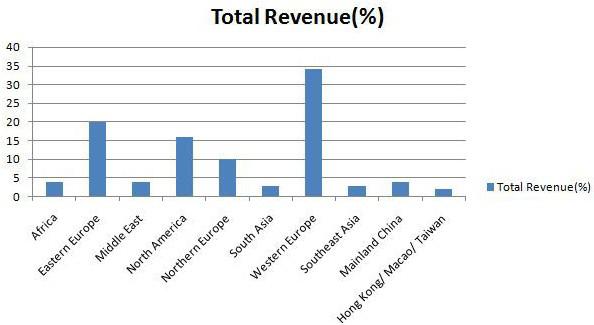

It's overseas Market