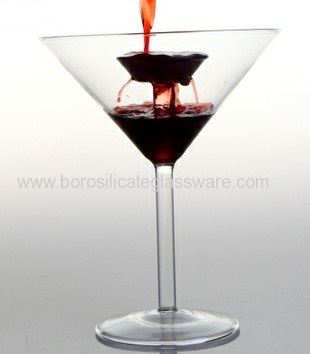

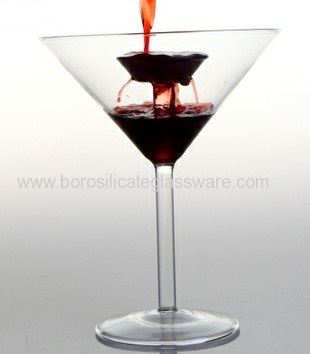

Mouth Blown borosilicate Wine glass,Cocktail Glass Shot glass Champagne glass

| Min. Order: | 2000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 50000 pcs/month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Glass Teapot/coffee Pot, Glass Mugs/cups, Glass Bongs, Glass Pipes/bubblers |

Product Detail

| Model No.: | MG010 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Height: | 15cm |

| Style: | Insulated |

| Material: | Glass |

| Capacity: | 300ml |

| Usage: | Wine |

| Brand Name: | C&C Glass |

| Material: | Borosilicate Glass |

| Crafts: | Hand Blown |

| Production Capacity: | 50000 pcs/month |

| Packing: | Client's Requirements |

| Delivery Date: | Depending on Order Quantity |

Product Description

Mouth Blown borosilicate Wine glass,Cocktail Glass Shot glass Champagne glass

Company Introduction

Being dedicated in the field of Glass Drinkware and Smoking ware for more than one decades, C&C Glass wish to introduce itself to you as one of the leading manufacturers specialized in Borosilicate Double Wall Glasses (Double wall glass cups and double wall glass teapots), Glass Teawares (glass teapots, glass teacups, glass tea warmer,etc);Glass Coffee wares(glass coffee pots, glass coffee cups); Wine Glasses and Bar Glasses(Martini glasses,Cocktail glasses,Champagne glasses and beer glasses);Glass Decanter,Glass Carafe; Glass Storage Jars; Glass Cruets; Glass Oil&Vinegar Bottles; Glass Water Pipes; Glass Bongs; Glass pipes; Glass Bubblers,etc

Borosilicate glass is a type of glass with the main glass-forming constituents silica and boron oxide. Borosilicate glasses are known for having very low coefficients of thermal expansion(~3 × 10−6 /°C at 20°C), making them resistant to thermal shock, more so than any other common glass.

In addition to the quartz, sodium carbonate, and aluminum oxide traditionally used in glassmaking, boron is used in the manufacture of borosilicate glass. The composition of low expansion borosilicate glass such as those laboratory glasses mentioned above is approximately 80% silica, 13% boric oxide, 4% sodium oxide, and 2-3% aluminum oxide. Though more difficult to make than traditional glass due to the high melting temperature required, it is economical to produce. Its superior durability, chemical and heat resistance finds excellent use in chemical laboratory equipment, cookware, lighting and, in certain cases, windows.

Borosilicate Glassware Features and Advantages

1,they are heat resistant,suitable for use in microwave,dishwasher and stove

2,offer a variety of application possibilities: baking and cooking, preparing and serving, cooling and freezing (down to -35°C/-31°F)

3.show a high resistance to sudden temperature changes with a temperature difference of 140°C/284°F(three times as high as normal glass or lead crystal glass)

4,are produced from clear borosilicate glass which is free of smell and flavor,does not discolor and show high chemical and mechanical resistance

5,do not give off any substances and therefore are suitable for allergy sufferers

6,are easy to clean and hygienic in use through the pore-free surface

7,come in superior and functional product design for an optimal preparation of beverage and meal