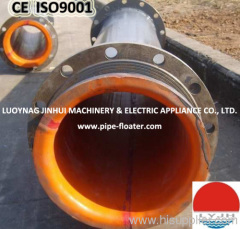

Rubber Lined Pipe Used for The Transport Pipelines of Ore

| Place of Origin: | Henan |

|---|

Company Profile

| Location: | Luoyang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | UHMWPE Pipe, UHMWPE Composite Pipe, HDPE Pipe, PVC Pipe, UHMWPE Sheets |

Product Description

We introduce the advanced production technology from Australian company by cooperation with it, and apply its bonding technology to the bonding between the rubber and steel pipe. We manufacture a hardness and softness of the pipeline equipment, using ordinary steel material as the steel pipe, and using excellent rubber with abrasion resistance, anticorrosion, heatresistance and so on as a lining layer to combine the characteristics of metal and rubber together, into the characteristics with high strength, high abrasion resistance, high anticorrosion and high heatresistance. It can be widely used for the pipeline system of industrial deslagging, exhaust in metallurgy, mining, electric undertaking, chemical industry and so on.

Our company's partner Australian Rubber Company (hereinafter as the Australian side)keep pace with a unique "liquid formulations, solidifying with room temperature" recipe and production technology with rubber in the rubber industry, and the microstructure of the rubber produced is almost not any damage, so that the products maintain a strong, high elasticity and natural features. This kind of rubber can be said "No other rubber can match" in the field of natural rubber, and it rules the roost nearly a hundred years so far.

Wear-resistant rubber lined pipe

Our wearresistant rubber lined pipe takes Import Wearresistant Rubber as the lining layer, by the the characteristics of strong rubber elasticity and low wearresistance, reduce the wear and tear of the pipe wall from conveying medium. Wearresistant rubber lined pipe can be used for the transport pipelines of ore, concentrates slurry and tailings slurry, and the transport pipelines of coal ash in the coalfired power plant, and the transport pipelines of the liquid with solid particles in chemical systems of the liquid delivery pipe.

Our wearresistant rubber lined pipe takes Import Wearresistant Rubber as the lining layer, by the the characteristics of strong rubber elasticity and low wearresistance, reduce the wear and tear of the pipe wall from conveying medium. Wearresistant rubber lined pipe can be used for the transport pipelines of ore, concentrates slurry and tailings slurry, and the transport pipelines of coal ash in the coalfired power plant, and the transport pipelines of the liquid with solid particles in chemical systems of the liquid delivery pipe.

Anti-corrosion rubber lined pipe

Rubber is a kind of material resistance to chemical corrosion, and widely used in acid, alkali, salt delivery systems. We can take different rubber such as styrene-butadiene rubber, natural rubber and chloroprene rubber as the lining according to the needs of different environments. The linings are perhaps hard rubber, half hand rubber or soft rubber, and the lining rubber also can be used interchangeably, or multilayer (for example a layer of hard rubber and a layer of soft rubber).

High-temperature Resistant rubber lined pipe

We take the excellent heatresistant rubber such butyl rubber, EPDM rubber and chlorosulfonated polyethylene fluorine rubber as the lining layer, and the pipes can work constantly at the environment with 140° C corrosive medium and steam for long time.

Rubber is a kind of material resistance to chemical corrosion, and widely used in acid, alkali, salt delivery systems. We can take different rubber such as styrene-butadiene rubber, natural rubber and chloroprene rubber as the lining according to the needs of different environments. The linings are perhaps hard rubber, half hand rubber or soft rubber, and the lining rubber also can be used interchangeably, or multilayer (for example a layer of hard rubber and a layer of soft rubber).

High-temperature Resistant rubber lined pipe

We take the excellent heatresistant rubber such butyl rubber, EPDM rubber and chlorosulfonated polyethylene fluorine rubber as the lining layer, and the pipes can work constantly at the environment with 140° C corrosive medium and steam for long time.

Rubber lined pipe Production Way

1. Blending adhesive agent

2. Cutting rubber sheet

3. Roughening rubber sheet

4. Cleaning rubber sheet

5. Brushing carrier oil

6. Spreading adhesive agent

7. Putting rubber sheet into steel pipe

8. Adjusting rubber sheet

9. Turn forming

Application of Rubber Lined Pipes

Our products are widely used in the equipment of gas discharge and desulfurization in power plant such as desulfurization tubes, acidic water storage tank, anion and cation cans, anion and cation tower, chimney flue of absorption tower, accidents slurry tank, limestone mortar tank, machine grinding recycling slurry boxes and so on; Coking plant; Gas works, and also in desulfurization tower, desulfurization pipelines, chemical salt equipment, evaporation tower, water treatment equipment, chemical pipelines.