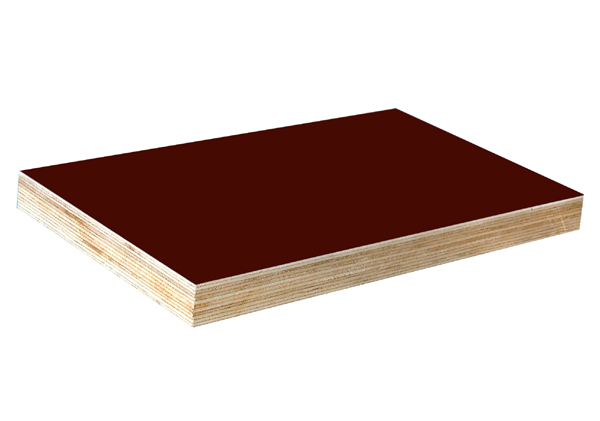

1220x2440mm brown WBP film faced plywood

11.0~1232.0 EUR

| Min. Order: | 111 Dozen |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | L/C, T/T |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Nanjing, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Plywood |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Product Material: | Bamboo |

| Special Function: | Security |

| Position: | Room |

| Open Style: | Sliding |

| Film Faced Plywood: | Film Faced Plywood |

Product Description

Specifications

Film Faced Plywood

1.Size: 1220x2440mm and 1250x2500mm

2.Thickness: 9mm, 12mm, 15mm, 18mm

3.Glue: WBP, MR, Melamine

1.Size: 1220x2440mm and 1250x2500mm

2.Thickness: 9mm, 12mm, 15mm, 18mm

3.Glue: WBP, MR, Melamine

Features of Film Faced Plywood :

1).Birch,poplar and hardwood core,

2. Glue: WBP, melamine,MR

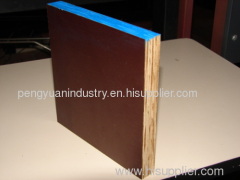

3.Film:Brown and black film

1).Birch,poplar and hardwood core,

2. Glue: WBP, melamine,MR

3.Film:Brown and black film

4.Core: Poplar, Birch and Hardwood

| film | dynea brown film,domestic brown film,anti-slipbrown film,black film |

| core | poplar,hardwood,eucalyptus,birch,combi,pine |

| glue | wbp(water-proof),mr,melamine |

| size | 1220mm*2440mm,1250mm*2500mm,1220mm*2500mm,915mm*1830mm,1500mm*3000mm,1525mm*3050mm |

| thickness | 6mm-45mm |

| usual | 6mm,9mm,12mm,15mm,18mm,21mm,24mm,25mm,27mm,30mm,35mm |

| thickness tolerance | +/-0.5mm |

5.Colour: Black and Brown

6.Outer packing:Pallet(covered by plywood andbundled with metal strips)

merit of our film faced plywood

1. No warping, no fracture, not out ofshape.

2. Transference to concrete is set up veryeasily, so good for construction work. (There is no need for any transferencepreparation.) It is easily to take off the membrane. It only takes the time 1/7of the steel mould. It can shorten the project time by 30%.

3. It is good to keep surface warm so in winterthe project can also be continued.

4. After installation of concrete, the surfacelooks like a mirror. (the cement does not stick.)

The wall or the surface of the building can bedecorated directly.

5. Thefilm faced plywood can be used to make camber and it also can be cut into smallpieces according the special requirements.

5. Thefilm faced plywood can be used to make camber and it also can be cut into smallpieces according the special requirements.

6. Environmentally friendly. (Even afterincineration, there is no hazardous substance.)

7. It can be used for a long time, and for the initialprice paid for the material, you will feel its value

7. It can be used for a long time, and for the initialprice paid for the material, you will feel its value