5-layer Corrugated Paperboard Production Line

100000.0~300000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Corrugated Paperboard Production Line |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Processing: | Packaging Line |

| Automatic Grade: | Semiautomatic |

| Type: | General |

| Usage: | Others |

| Packaging: | Metal |

| Brand Name: | Royal packing |

| Production Capacity: | 10 |

| Packing: | hard wooden pallet |

| Delivery Date: | 20 days |

Product Description

Introduction

Corrugated cardboard production line includes mill roll stand, single facer, pre-heater, conveyer bridge, gluing machine, slitter scorer machine, cut off machine and stacker. We can produce the three ply, five ply and seven ply corrugated cardboard production line, Widths from 1400 to 2500mm\min,production speeds from 60 to 250 meters/min Customer's can choose according his own needs. We can provide a complete production line and can also provide individual parts to complete customer's own line.

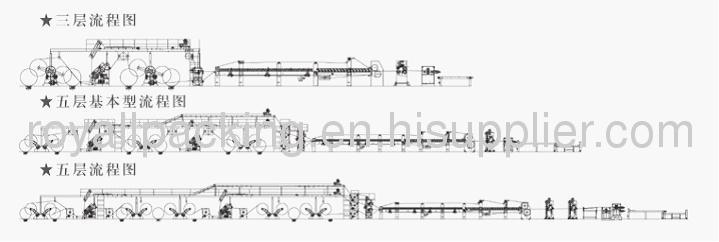

Common Design Chart

Equipments List

Equipments Name | MJF-80-1800 Economic | MJF-120-1800 Middle-speed | MJF-180-1800 High-speed |

Mechanical Roll Stand (include the paper roll rail.) | 3unit | 5units | |

Hydraulic Roll Stand (include the paper roll rail.) | 5units | ||

Pre-heater Ф600mm | 4units | ||

Pre-heaterФ900mm | 4units | ||

Pre-heaterФ1000mm | 4units | ||

Vacuum Single Facer (RollФ280), gimbal drive | 2units | ||

Vacuum Single Facer (RollФ320), gimbal drive | 2units | ||

Vacuum Single Facer (RollФ380), gimbal drive | 2units | ||

Transport Bridge (Electrical adjust the precision, vacuum tighten and loosen.) | 1set | ||

Heavy model transport bridge (Electrical adjust the precision, vacuum tighten and loosen.) | 1set | 1set | |

Triple preheater Ф600mm | 1units | ||

Triple preheater Ф900mm | 1units | ||

Triple preheater Ф1000mm | 1units | ||

Double Gluer - B | 1units | 1units | |

Heavy model double gluer -C | 1units | ||

Double baker (600mm X14heat plates, 6meter cooling part.) | 1units | ||

Double baker (600mm X15heat plates, 7meter cooling part.) | 1units | ||

Double baker (600mm X18heat plates, 9meter cooling part.) | 1units | ||

High-Speed Thin Blade(Electrical up and down, electrical adjust the precision.) | 1units | 1units | |

NC Thin Blade (Computer control) | 1units | ||

NC Cutter (Servo, straight knife.) | 1units | 1units | |

NC Cutter (Servo, spiral knife.) | 1units | ||

Paperboard Conveyor (right-angle shape) | 1units | ||

Stacker | 1units | 1units | |

Glue System | 1set | 1set | |

Steam System (Not include boiler and pipes) | 1set | 1set | 1set |

Technological Parameters

Technological Parameters | MJF-80-1800 Standard | MJF-120-1800 Middle-speed | MJF-180-1800 High-speed |

Line size L*W*H(m) | 56×4.5×4.2 | 67×4.5×4.2 | 82×4.5×4.5 |

Factory size L*W*H(m) | 60×11×5 | 72×11×5 | 88×11×6 |

Total Power (about) | 100kw | 180kw | 250 kw |

Steam Cost | 0.8~1.2Mpa (Advise 2t/h boiler) | 0.8~1.2Mpa (Advise 4t/h boiler) | 0.8~1.2Mpa (Advise 4t/h boiler) |

Starch Cost (g/m2) | 20-26 | 20-26 | 20-26 |

Raw paper width (mm) | 1800 | 1800 | 1800 |

Mechanical Speed | 80m/min | 120 m/min | 180m/min |

Economical speed | 60m/min | 90m/min | 150 m/min |

Shift capacity (*104m/8h) | 3 | 4.5 | 9 |

Transversely cutting precision | ±1 | ±1 | ±1 |

Transversely cutting scope (mm) | 500-9999 | 500-9999 | 500-9999 |

Slitting scope (mm) | 145-1800 | 160-1800 | 160-1800 |

Slitting precision (mm) | ±1 | ±1 | ±1 |

Workers | 8-11 | 8-11 | 8-11 |

Note: Above parameters are for your reference. It depends on the different machines you choose.

.jpg)