Flame Resistant Conveyor Belt

2.0~5.0 USD

| Min. Order: | 100 Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000meter/Month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Baoding, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Rubber Conveyor Belts, Conveyor Idlers, Conveyor Pulley |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Production Capacity: | 10000meter/Month |

| Packing: | roll with woven bag and packing string |

| Delivery Date: | 15 days |

Product Description

1. Flame Retardant Conveyor Belt Usages:

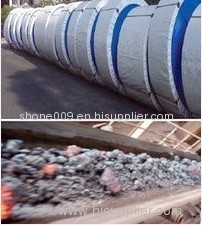

The flame resistant conveyor belt is mainly used under mine.

2. Flame Resistant Conveyor Belt Feature:

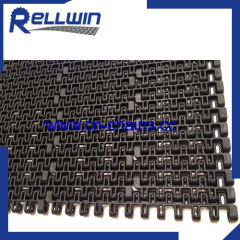

The belt carcass shall not delaminate, with small rate of elongation, strong shock resistance, tear resistance. It contains PVC (plastic face), PVG (PVC covered with additional rubber surface) solid woven flame retardant belt, it shall be in accordance with MT/914-2002.

PVC type is applicable to conveying the material at the angle of inclination of less than 16 degree under drying condition, and conveying the watery material at the angle of inclination of less than 20 degree.

Type N/mm tensile strength:

Level | Level 4 | Level 5 | Level 6 | Level 7 | Level 8 | Level 9 | Level 10 |

Type | 680S | 800S | 1000S | 1250S | 1400S | 1600S | 1800S |

3. Flame Retardant Conveyor Belt Safety Feature

The conveyor belt has passed the flame retardant test and electrostatic test, and has certificate of conformity with coal mine safety symbol and been accepted by clients.

1) Flame Retardant Conveyor Belt Mechanical Property:

Given the excellent mechanical property, it is characterized by the longest service life and economy in installation and service;

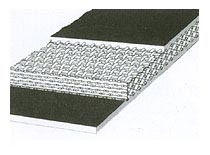

2) The longest service life: the service life of the belt carcass is dependent on the following factors: the solid woven belt carcass through spinning and weaving of the filament and cover cotton in warp-wise and width-wise;

3) Flame resistant conveyor belt is characterized by the solid woven flame retardant belt, wear resistance, antistatic, water resistance, flame retardation, high strength, excellent safety feature, as well as low cost, low price compared with other flame retardant conveyor belt, therefore, it is one of the popular and prevailing flame retardant conveyor belts, it is applicable to the conveying in underground with mild slope;

4) Flame Resistant Conveyor Belt Joint Property:

According to the strength and structure of the belt carcass, adopting the mechanical buckle for connection, its strength is up to 50%-90% of the strength of the belt strength; adopting vulcanized joint, its strength is up to 60%-90% of the strength of the belt. A variety of joints shall satisfy the requirements of client so as to ensure the system safety and high efficient operation;

Type of conveyor belt model | PVC(mm) | PVC(mm) |

680S | 1.5+1 | 2+1 |

800S | 2+1 | 2+1 |

1000S | 2+1 | 2+1 |

1250S | 2+2 | 2+1.5 |

1400S | 3+2 | 2.5+1.5 |

1600S | 3+2 | 2.5+1.5 |

1800S | 3+2 | 3+2 |

2000S | 5+2 | 3+2 or 4+2 |

5) Flame retardant property:

Friction of the drum: the surface temperature of the drum shall be no more than 325 ℃.

Burning time of the blow lamp: The flame time average of the blow lamp for the full thickness specimen shall be no more than 3.0 S, and the flame time average without cover layer shall be no more than 5.0 S.

6) Burning of propane: the length of the non destructive part shall be more than 250 mm;

Surface resistance: The average value of the resistance values of the upper surface and undersurface shall be no more than 3.0×10Ω;

.jpg)

.jpg)