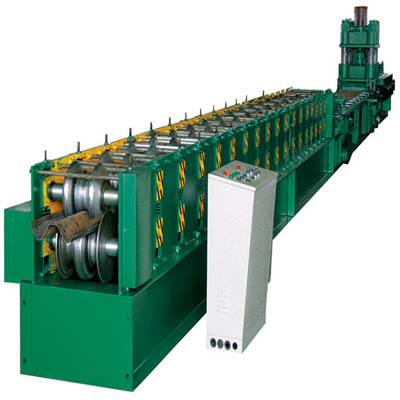

Guard Rail Roll Forming Machine

| Place of Origin: | Hebei |

|---|

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Roll Forming Machine, Conveyor Belt |

Product Detail

| Hydraulic Pressure: | Hydraulic |

|---|

Product Description

The structure of equipment

1. Hydraulic decoiler

Single unrolling machine, one side can put material

Adopt automatic hydraulic system

Coil weight (Max): 7000kg

Coil dia (Max): 1600mm

Oil cylinder dia: 1200mm working pressure: 10mpa

Coil Width(Max. ): 500mm

2. Feeding, leveling

Feed into unit oriented wheel(can right and left adjust)

Into feeding roller, dia is ¢ 180mm, material 45# steel, quenched 48-52, chromed

Leveling is three roller above and four roller below, quenched and chromed

3. Punching (can right and left adjust)

Using hydraulic punching

Oil cylinder dia: 140mm

Working pressure: 20mpa

Mould material: Cr12 quenched 58-62

Hydraulic power: 7.5kw

Size: 1.5m long*1.1m wide*1.2m high

4. Roll forming

Main motor power: 45kw

Decelerating motor: BWD14-43-37kw, made in Shanghai or

Changzhou

Drive: Gimbal driving, 120*500

Main shaft dia: 100mm material: 45#forge steel

Roller material: GCR15 quenched 58-62, chromed

Roll station: 17stations

Timing by transducer: 5m--20m/min(not including punching)

Transducer: Panasonic made in Japan. 380V 50Hz

Computer: PLC

Computer operating panel: Touching screen

5. Cutting

Hydraulic cut

Knife material: Cr12, quenched 58-62

Oil cylinder dia: 250mm

Working pressure: 30mpa

Working journey: 80mm

6. The Outside size:

18m long*2.2m wide*1.5m high

7. Run out table

Jointed by 60mm*40mm tube (can be adjusted to up and down)

Size: 1.5mlong*0.8mwide*0.6-1mhigh(can be adjusted)

The parts of machine

Hydraulic passive Uncoiled, Forming Machine ( feeding, leveler, roll mill, cutting, punching, PLC computer, Hydraulic station, cutting), and simple run out shelves 3PCS, packing list 1 PCS.

8. The production flow of equipment

Decoiling_Feeding(take the sheet to the first station)_leveling----Punching of the sheet _roll forming----hydraulic cut to length-product packing manual.

1. Hydraulic decoiler

Single unrolling machine, one side can put material

Adopt automatic hydraulic system

Coil weight (Max): 7000kg

Coil dia (Max): 1600mm

Oil cylinder dia: 1200mm working pressure: 10mpa

Coil Width(Max. ): 500mm

2. Feeding, leveling

Feed into unit oriented wheel(can right and left adjust)

Into feeding roller, dia is ¢ 180mm, material 45# steel, quenched 48-52, chromed

Leveling is three roller above and four roller below, quenched and chromed

3. Punching (can right and left adjust)

Using hydraulic punching

Oil cylinder dia: 140mm

Working pressure: 20mpa

Mould material: Cr12 quenched 58-62

Hydraulic power: 7.5kw

Size: 1.5m long*1.1m wide*1.2m high

4. Roll forming

Main motor power: 45kw

Decelerating motor: BWD14-43-37kw, made in Shanghai or

Changzhou

Drive: Gimbal driving, 120*500

Main shaft dia: 100mm material: 45#forge steel

Roller material: GCR15 quenched 58-62, chromed

Roll station: 17stations

Timing by transducer: 5m--20m/min(not including punching)

Transducer: Panasonic made in Japan. 380V 50Hz

Computer: PLC

Computer operating panel: Touching screen

5. Cutting

Hydraulic cut

Knife material: Cr12, quenched 58-62

Oil cylinder dia: 250mm

Working pressure: 30mpa

Working journey: 80mm

6. The Outside size:

18m long*2.2m wide*1.5m high

7. Run out table

Jointed by 60mm*40mm tube (can be adjusted to up and down)

Size: 1.5mlong*0.8mwide*0.6-1mhigh(can be adjusted)

The parts of machine

Hydraulic passive Uncoiled, Forming Machine ( feeding, leveler, roll mill, cutting, punching, PLC computer, Hydraulic station, cutting), and simple run out shelves 3PCS, packing list 1 PCS.

8. The production flow of equipment

Decoiling_Feeding(take the sheet to the first station)_leveling----Punching of the sheet _roll forming----hydraulic cut to length-product packing manual.