Flotation Beneficiation Plant

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 sets/month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Mining Machine |

Product Detail

| Application: | Coal |

|---|---|

| Type: | Others |

| Production Capacity: | 200 sets/month |

| Packing: | normal packing |

| Delivery Date: | 20 days |

Product Description

Company introduction

We Henan Zhongke Engineering & Technology Co., Ltd. is a manufacturer and exporter of building material equipment & mining machinery in China.

Our main products are AAC block production line, stone crushing plant, cement machinery, active lime production line, jaw crusher, impact crusher, ball mill, rotary kiln, dryer, dust catcher, and etc.

All products are manufactured in strict accordance with ISO 9001:2008 quality standards. We do best quality products, and provide our best service for customers from home and abroad.

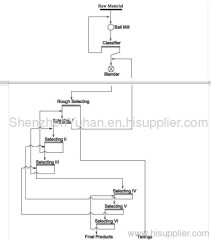

flotation beneficiation plant

famous ore flotation machine Detailed Product Description

This machine is used for separating ferrous and non-ferrous metals. It can also be used for separating non-metals like coal fluorite and speckstone. The impeller is rotated by V-belt of electric motor and produces centrifugal function resulting in negative pressure. One hand, it sucks into enough air to mix with pulp and fine the foam in order that the mineral can stick on the foam. Then it turns into mineral foam after floating on the pulp. Adjust the height of stopper to control fluid level in order that the available foam can be scrapped out by scrappers.

famous ore flotation machine work principle

The flotation machine is driving by the driving band operated by the motor and this mill bring the centrifugation and negative pressure .in this condition ,enough ,air will mix with the slurry and at the same time the slurry and chemical will mix very well to make the mineral adhesion to the bubble.the height of shutter can be adjustment to scapte the usful bubble.

famous ore flotation machine feature

The floatation machine has the advantages of large air-absorption capacity and low energy consumption. Every cell owns three functions: air absorption, slurry absorption, and floatation separation, and the cells form a floatation separation loop by itself without any auxiliary equipment, and is allocated horizontally, which favors the change of flow. The circulation of mineral slurry is reasonable, and can avoid the disposition of coarse sand to the largest extent. There is self-control device on the surface of mineral slurry, so it is easy to adjust it. The impeller has backward-inclined upper and lower vanes, which produce upper and lower circulation of mineral slurrry respectively.

famous ore flotation machine technical parameters

Model | Effective volume | Processing ability | The motor power | Spindle speed | Scraper speed | Scraper power | Trough size | The single slot weight |

SF-0.37 | 0.37 | 0.2-0.4 | 1.5 | 352 | 25 | 1.1 | 700X700X750 | 468 |

SF-0.7 | 0.7 | 0.3-0.9 | 3 | 400 | 25 | 1.1 | 900X820X950 | 600 |

SF-1.2 | 1.2 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1100X1100X1100 | 1873 |

SF-2.8 | 2.8 | 1.5-3.5 | 11 | 268 | 25 | 1.1 | 1750X1600X1150 | 2538 |

SF-4 | 4 | 2.0-4.0 | 15 | 220 | 25 | 1.5 | 1850X2050X1200 | 2838 |

SF-8 | 8 | 4.0-8.0 | 30 | 191 | 25 | 1.5 | 2200X2900X1400 | 4129 |

SF-10 | 10 | 5.0-10 | 30 | 191 | 25 | 1.5 | 2200X2900X1700 | 4486 |

SF-20 | 20 | 5.0-20 | 30X2 | 191 | 25 | 1.5X2 | 2850X3800X2000 | 9828 |