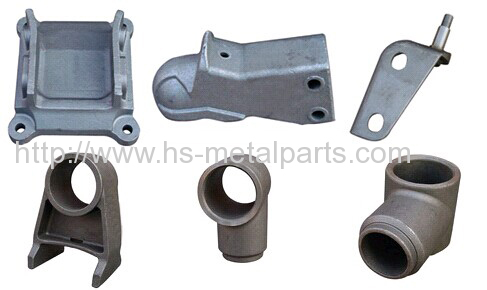

OEM Iron investment casting elements

| Trade Term: | FOB,CFR,CIF,EXW |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000 Piece/Pieces per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | 1 Investment Casting Construction Parts HS CC 03, Alloy Steel Hot Forging Parts HS DF 08, Automotive Casting Parts Truck Parts Etc., CNC Machining Stainless Steel Machining Parts Aluminum Machining Parts Iron Machining Parts Carbon Machining Parts, Aluminum Casting Equipment Parts |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | OEM |

| Material Capabilities: | Iron, Steel, Aluminum,Brass,Bronze,Copper,Hardened Metals |

| Process: | Investment casting |

| Measurement:: | Depends on client's option |

| Surfacte treatment: | Spray painting |

| Inspection: | 100% in house |

| Packaging: | Wooden case or as requirement |

| Quality Certificate: | ISO9001:2008 |

| Price term: | FOB Ningbo, CIF |

| Payment: | T/T, L/C |

| Delivery port: | Ningbo |

| Production Capacity: | 10000 Piece/Pieces per Month |

| Packing: | According to customer's requirement |

| Delivery Date: | 45--60days |

Product Description

Material capability: Alloy steel, Carbon steel, High resistant stainless steel, Ductile iron, High chromium iron, Gray iron

Casting technique: Investment casting( Lost wax casting), precision casting, lost foam casting) and steel sand casting process.

Procedure: Casting, Surface treatment, Heat treatment, Machining, Polishing, Packing and delivery

surface treatment after casting, such as machining, polishing, plating, etc.

Items: FOB Ningbo or Shanghai,China

Lead time:45--60 days

Casting tolerance: ISO / GB CT 7~ 9

Casting Standard: ASTM, SAE, ISO, DIN, GB, BS, GOST

Main production equipments: Wax injection, CNC-machine, Machine-center, Heat treatment furnace.

Place of origin: Ningbo,China

Main market:United States,Canada,UK, Holland, France, Germany, Denmark, Australia, Sweden, Finland, Russia, Spain, Portugal. Italy, etc.

Software for specification drawing: JPG, Auto CAD

Machine parts ( machining parts. Machinery parts) , metalwork ( metal products) and stamping parts are suitable for us.

They are using for auto machine or others.

Process | Material Capacity | Standard | |

Sand casting | Green sand | Grey Iron, Ductile Iron, Malleable Iron, Stainless steel, Carbon steel, Aluminum, brass, bronze, copper, Alloy steel | ASTM BS JIS DIN etc. |

Furan Resin sand | |||

Gold Harden Resin sand | |||

Investment casting | Sodium Silicone( Water glass) | Stainless steel, Carbon steel, Alloy steel, Bronze, brass, Aluminum | |

Silica Sol | |||

Forging | Hammer Forging | Stainless steel, carbon steel, Alloy steel, brass, Aluminum | |

Die Forging | |||

Roll Forging | |||

Stamping | All Metal material | ||

Machining | |||

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.