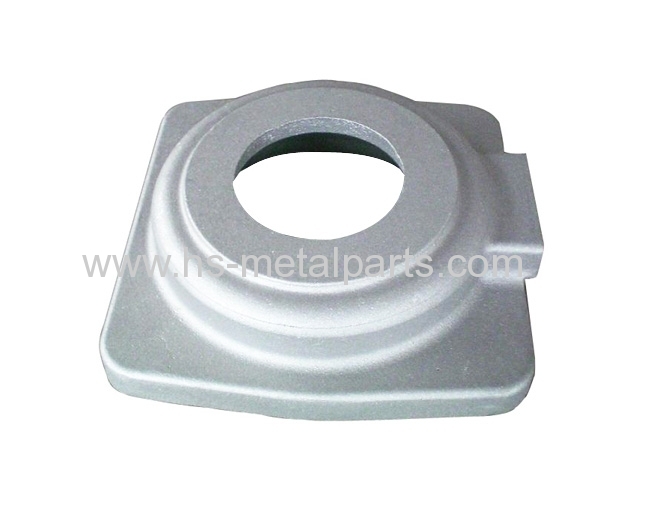

Aluminum Die casting parts for machinery

| Trade Term: | FOB,CFR,CIF,FCA,EXW |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000 pairs per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | 1 Investment Casting Construction Parts HS CC 03, Alloy Steel Hot Forging Parts HS DF 08, Automotive Casting Parts Truck Parts Etc., CNC Machining Stainless Steel Machining Parts Aluminum Machining Parts Iron Machining Parts Carbon Machining Parts, Aluminum Casting Equipment Parts |

Product Detail

| Means of Transport: | Ocean, express, Air |

|---|---|

| Materials: | Aluminum |

| Craft: | Die casting and CNC machining |

| Finish: | Oxidizing |

| Application: | 10000pieces per month |

| Minimum order quantity: | 1 Piece accept sample order |

| Tolerance: | 0.05mm to 0.1mm |

| Quality certificate: | ISO9001:2008 |

| Price term: | FOB Ningbo, CIF |

| Payment: | T/T, L/C |

| port: | Ningbo |

| Production Capacity: | 10000 pairs per Month |

| Packing: | According to customer's request |

| Delivery Date: | 45--60 days |

Product Description

Product Description

Product Description

1) Product Name:Aluminum die casting

2) Material: Aluminum alloy

3) Applicable Industry: Auto parts, motor shell, pump parts, machinery parts,lamp chimney.

4) Applied file format: Auto CAD, Solid work;

Company Profile:

With plentiful experience and skillful technique, It has the full capacity to produce the best aluminium die casting as per our customers drawing or sample and we enjoy a good reputation in domestic and overseas market.

Casting parts | Sol silicon casting |

Materials | Stainless steel Alloy steel Carbon steel Cast iron Brass Aluminium casting: 319, 355, A356. Magnesium casting: A291D, AM60B Zinc casting: ZA-12, ZA-27 |

Production procedure | 1.Designing drawing |

Application | · Auto parts |

Certification | ISO9001:2008 |

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.

.jpg)