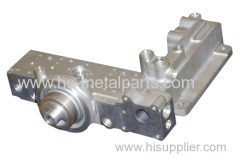

Green sand casting equipment parts

| Trade Term: | FOB,CFR,CIF,EXW |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000 pairs per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | 1 Investment Casting Construction Parts HS CC 03, Alloy Steel Hot Forging Parts HS DF 08, Automotive Casting Parts Truck Parts Etc., CNC Machining Stainless Steel Machining Parts Aluminum Machining Parts Iron Machining Parts Carbon Machining Parts, Aluminum Casting Equipment Parts |

Product Detail

| Means of Transport: | Ocean, express, Air |

|---|---|

| Brand Name: | OEM |

| Materials: | Aluminum |

| Technics: | Sand casting |

| Size: | As drawing |

| Draws: | Pro/E, Auto CAD, Solidwork, etc. |

| Machining: | CNC, milling, drilling, CNC lathe, etc. |

| Standard: | Non standard |

| Weight: | 0.5Kg to 100Kg |

| Price term: | FOB Ningbo, CIF |

| Payment: | T/T, L/C |

| Delivery port: | Ningbo |

| Production Capacity: | 10000 pairs per Month |

| Packing: | According to customer's request |

| Delivery Date: | 45--60days |

Product Description

Material | A360, A380, A356, ADC12 |

Certificate | ISO9001:2008 |

Standards | ASTM, AISI, BS, DIN, JIS, NF |

Heat Treatment | T6 Heat Treatment |

Surface finish | Sandblasting, painting, polishing |

Inspection instruments | Sectrum analyzer & CMM |

Applied software | Pro/E,Auto CAD,SolidWork ,CAXA, UG, CAD/CAM/CAE |

Machining equipments | -Gravity Casting machine -10 Sets |

Product range | Auto parts, motor parts, pump partp parts, machinery parts |

Service | OEM service available |

Product Application | Hydraulics Valves Power Tools Off Road Truck Machine Tools Lab Equipment Medical Fluid Controls Gear Boxes Construction Railroad Recreation |

Green Sand

Green sand system and molding process is a continuous recycling act. Following shakeout, the used sand is sent back to the sand muller and with minimal additives, it is ready again to produce additional molds. Of the approximate 100 tons of sand continually used on a daily basis, only a mere 200 lbs of new silica sand is required to be added to the system.

Core Sand

Currently all of our used core sand is transported from our facility to be used as landfill cover and road bed aggregate. Our process of resin binder is water based, rather than petrochemical solvents, which will dramatically reduce the amount of VOC and HAP emissions.

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.

.jpg)

.jpg)