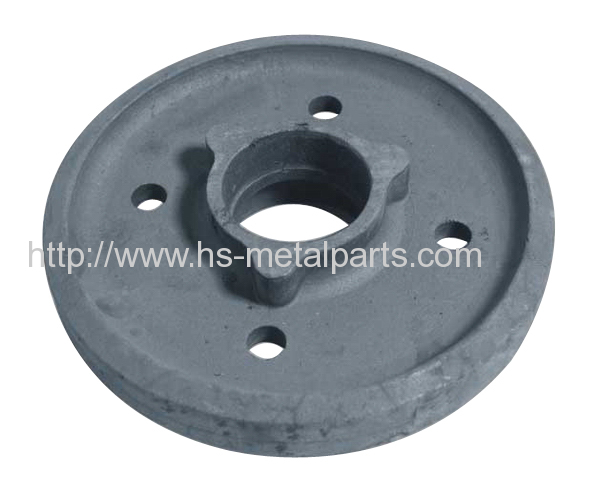

Aluminium Water glass casting Farming Machinery Parts

| Trade Term: | FOB,CFR,CIF,EXW |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 8000T/ Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | 1 Investment Casting Construction Parts HS CC 03, Alloy Steel Hot Forging Parts HS DF 08, Automotive Casting Parts Truck Parts Etc., CNC Machining Stainless Steel Machining Parts Aluminum Machining Parts Iron Machining Parts Carbon Machining Parts, Aluminum Casting Equipment Parts |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Brand Name: | OEM |

| Standard: | JIS, DIN, ASTM, BS |

| Material Capabilities: | Aluminum, Alloy steel, Carbon steel, stainless steel |

| process: | investment casting |

| Packing: | Wooden case, Hardboard box, Iron box etc |

| Dimension Tolerance: | CT7 |

| Surface Roughness: | Ra6.4~12.5 |

| Application: | Industry, machinery, auto parts, etc |

| Quality Certificate: | ISO9001:2008 |

| Casting Weight: | 0.5-100Kg |

| Certificate: | ISO9001 2008 |

| Production Capacity: | 8000T/ Month |

| Packing: | Wooden case, Hardboard box, Iron box etc |

| Delivery Date: | 45--60 days |

Product Description

Casting parts · Sand casting, · Plaster casting,· Lost wax casting, · Investment casting

Materials

· Aluminum casting: 319, 355, A356,

· Magnesium casting: A291D, AM60B

· Zinc casting: ZA-12, ZA-27

· Grey cast iron

· Nodular cast iron

· Stainless steel cast

· Brass cast

· Bronze cast

Production procedure

1.Designing drawing

2.Opening mould

3.casting

5.Surface treatment : polish, electrophoresis, painting, anodizing, powder coating etc.

6.Inspection and packing

Application

· Auto parts, · Medical parts, · Machine parts, Aerospace machinery parts, · Ships equipment parts, · Electrical parts, · Furniture parts, · Kitchen tools, · Telecommunications

A world class manufacturer & supplier of lost wax investment castings in carbon steel and alloy steel, is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry & machining factory. Precision casting parts are exported to markets in Europe, America ,Australia and Japan. Our company adopts the modern industrial management style, promotes ISO9001: 2002 and TS16949:2002 quality management system. We achieved the win-win situation for company's profit and environment protection.

Material | Aluminum casting: 319, 355, A356, QAl11-6-6, CuAl10Fe2/3, CuAl10Ni5Fe5, C65500, C95600, C87500, · Magnesium casting: A291D, AM60B · Zinc casting: ZA-12, ZA-27 · Grey cast iron · Carbon steel:45#, 20# · Nodular cast iron · Stainless steel cast 304, 316 · Brass cast HPb59-1, CuZn39Pb1/2/3, CuZn40, C36000, C37710, C67400, · Bronze cast |

Applied file format | Auto CAD, Solid work, Pro/E, PDF etc. |

Casting process | Waster glass casting, Sand casting, Die casting, Investment casting, Plaster casting,· Lost wax casting etc. |

Processing methods | CNC machining, general engineering, turning, drilling, polishing, knurling, tapping, threading, burnishing, slab milling, face milling and end milling |

Applicable Industry | Auto parts, motor shell, pump parts, machinery parts, lamp chimney. |

Machining | CNC lathe, four-axis Milling center, CNC Milling machine, Vertical machining center, Universal turret milling machine, Universal Radial milling machine, wire cutting |

Available surface | Zinc plated, Nickel zinc, polishing, Nickel plated, Chrome plated, spray paint, powder anodizing, Electrophoresis, Black anodizing, Mirror polishing, spraving anti_rust oil, etc. |

Application filed | Automobile, Industry machine, farm equipment, truck, railway, medical equipment etc. |

Heat treatment | Annealing, Tempering, Carbonitriding, Normalizing etc. |

Package | Corrugated cases Composite material box As special required when order |

Payment | Tooling Charge:50% T/T in advance, 50% against with the sample For sample order 100% in advance For normal order 30% in advance and 70% before shipping or against with copy of B/L. L/C:100% L/C at sight |

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminum alloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.