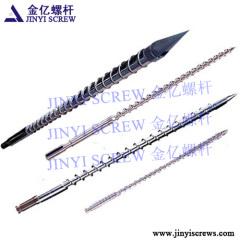

plastic injection machine screws

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1 set |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Conical Twin Screw Barrel, Parallel Twin Screw Barrel, Screws For Injection Machine, Injection Molding Machine Barrel, Extruder Machine Screw And Barrel |

Product Detail

| Model No.: | WD 046 |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | WEIDA |

| Nitrided Layer Hardness: | 950-1020Hv |

| Nitriding Treatment Time: | ≥ 96 hours |

| Production Capacity: | 1 set |

| Packing: | wooden case |

| Delivery Date: | 25 days |

Product Description

screw for Plastic Injection Molding Machine

Technical Index

Working Process :

Raw Material → Quenching & Tempering → Rough Machining → Semi finish Machining → Finish Machining → Nitriding Treatment → Bimetallic Casting → Inspection → Finish Products

Technical Index

Steel Material | 38CrMoALA,SKD61,SKD11,D2 etc. |

Hardness after Hardening & Tempering | HB240-280 |

Nitriding Treatment Time | ≥ 96 hours |

Nitrided Layer Hardness | 950-1020Hv |

Nitrided Layer Thickness | 0.5-0.8mm |

Surface Roughness Degree | Ra0.4um |

Surface Hardness Degree | 58-64 HRC |

Screw Straightness Degree | 0.015mm |

Chromium-Plated Surface Hardness After Nitriding | ≥ 900HB |

Chromium-Plating Layer Thickness | 0.05-0.10mm |

Bimetallic Layer Hardness | 50-65HRC |

Depth Of Alloy Layer | 0.8-2.0mm |

Grade List

Grade | Steel Material | Processing |

Standard Grade | 38CrMoALA | Nitriding 96 Hours |

Bimetallic Grade | 38CrMoALA | HP/HVOF Spraying |

TC-A Grade | Tungsten Carbide40% | Centrifugal Casting |

TC-B Grade | Tungsten Carbide25% | Centrifugal Casting |

TC-C Grade | Tungsten Carbide10% |

Material Available

Nitrided Steel | 42CrMo,38CrMoALA,etc. |

Cool Work Steel | D2,SKD61,9Cr18MoV etc. |

Heat Resistant Steel | SKH51, GH113 etc. |