GO YEN CA-25MM RCA-25MM 1" MM series Pulse jet valve

10.0~22.0 USD

| Min. Order: | 10 Units |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 1000 units per week |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | SCG353A047 1 1/2 0.35-0.85Mpa ASCO Pulse Jet Vave, 2 Way Solenoid Valve, 2 SCG353A050 ASCO Diaphragm Impulse Valves |

Product Detail

| Model No.: | CA-25MM RCA-25MM |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Power: | Pneumatic |

| Standard or Nonstandard: | Standard |

| Pressure: | Low Pressure |

| Structure: | Diaphragm |

| Material: | Casting |

| Temperature of Media: | Normal Temperature |

| Media: | Gas |

| Brand Name: | Others |

| Production Capacity: | 1000 units per week |

| Packing: | Plastic bags,Boxes,cartons or Customer's request |

| Delivery Date: | within 15 working days after payment |

Product Description

Very high performance diaphragm valve designed to be mounted directly into the compressed air manifold. 1" and 1.5" models are supplied with outlet pipes to length specified, 3" and 3.5"models are supplied without outlet pipes.

Suitable for

Dust collector applications, in particular for reverse pulse jet filter cleaning including bag filters, cartridge filters, envelope filters, ceramic filters, and sintered metal fibre filters.

Construction

Construction

Body and Dresser Nuts: Diecast Aluminium

Ferrule: 304 SS

Armature: 430FR SS

Diaphragm and Seals: Nitrile or Viton (reinforced)

Spring: 304 SS

Screws: 302 SS

Outlet Pipe: Schedule 40 wrought steel zinc passivated

Diaphragm Seat: PA-6 (25 & 40MM standard), Nitrile coated mild steel (76MM standard), or Viton coated mild steel (all sizes)

Refer to Q Series Solenoid product data sheet for solenoid construction details.

Operation

Recommended on time range: 50-500ms

Recommended time between pulses: 1 minute or greater

Maintenance

Before conducting any maintenance activity on the system ensure that components are fully isolated from pressure and power supplies. Pressure and power should not be reapplied until the valve has been fully assembled. Diaphragm and pilot inspection should be conducted annually.

Installation

Installation

1. MM valves are installed through the tank, refer to the appropriate template listed above.

2. To avoid any potential operational problems it is preferable that the valves are

not mounted underneath the tank where condensation may collect. All o-rings

should be coated with a silicone based lubricant or similar.

3. Dresser nut seals where used are a pressure seal only, not a structural component. Do not rely on dresser seals to retain either the tanks or blowtubes. Tanks and blowtubes must be independently restrained.

4. Tighten dresser nuts to 20Nm (15 ftlbs) max.

5. Tighten pipe outlets to 20 Nm (15 ftlbs).

6. Connect to pilot valve, if remotely actuated.

7. Ensure compressed air supply is dry and free from oil and dirt.

8. Check all cleaning system components are secure before applying pressure.

9. Apply moderate pressure and check for leaks.

10.Fully pressurise system.

11 .Test fire and listen for proper actuation and crisp pulse noises.

Approvals

Integrally piloted valves meet the requirements of:

. Atex II 2D Mechanical

. CSA (C&US)

C22.2 No. 139-1982 UL Std No. 429

. C-Tick - integral pilots

. EMC (89/336/CE) - integral pilots

Voltage: DC12V,DC24V,AC36V,AC110V,AC220V,AC380V

Pressure Range: 30(5)-860(125) kPA(Psi)

Voltage: DC12V,DC24V,AC36V,AC110V,AC220V,AC380V

Pressure Range: 30(5)-860(125) kPA(Psi)

Temperature Range: Nitrite Seals: -40°C (-40°F) to 82°C(179.6°F) Viton Seals: -29°C (-20.2°F) to 232°C (449.6°F)

Nominal Size,Weights, Product Characteristics and Performance:

Nominal Size,Weights, Product Characteristics and Performance:

| Model | Nom. | Port Size | Weight | Diaphragm Kits | Flow | ||||

| Size | mm | inch | Integral Pilot (CA)Kg(lbs) | Remote Pilot (RCA)Kg(lbs) | Nitrile | Viton | KV | CV | |

| CA/RCA25MM | 25 | 25 | 1 | 0.72(1.59) | 0.50(1.10) | K2501 | K2503 | 26 | 30 |

| CA/RCA40MM | 40 | 40 | 1.5 | 1.12(2.47) | 0.90(1.98) | K4000 | K4007 | 44 | 51 |

| CA/RCA76MM | 76 | 76 | 3 | 3.90(8.60) | 3.68(8.11) | K7600 | K7601 | 200 | 233 |

| CA/RCA102MM | 102 | 102 | 3.5 | 3.90(8.60) | 3.68(8.11) | K10200 | K10201 | 238 | 277 |

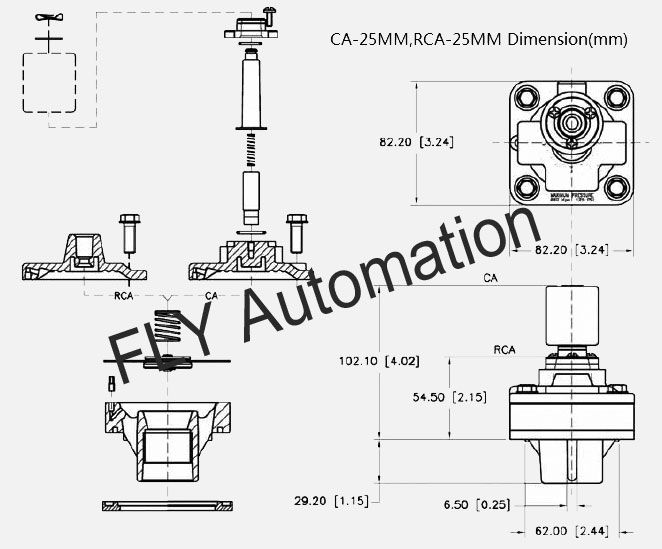

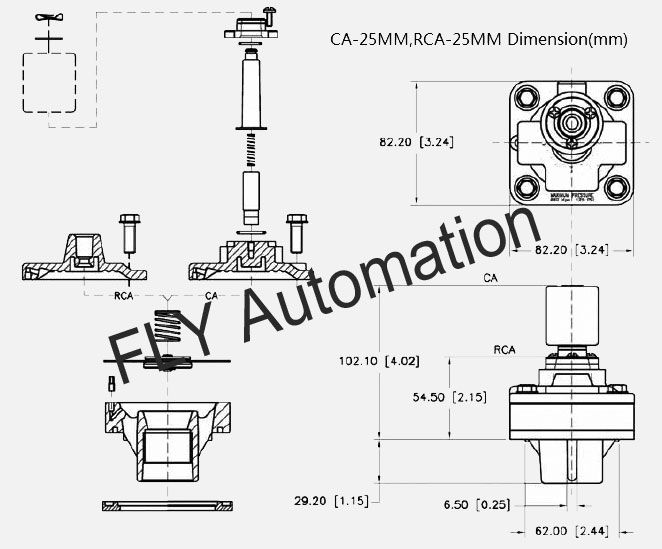

Dimension(mm and inch):