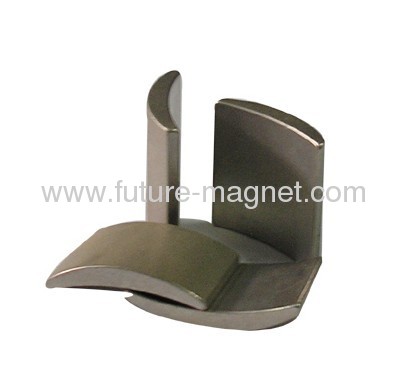

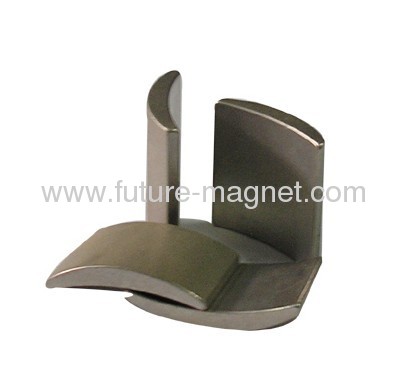

Super Strong Sintered NdFeB Arc Magnet

0.01~100.0 USD

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000000pcs/M |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Sintered Ndfeb Magnet |

Product Detail

| Model No.: | N35-N5235M-50M35H-50H35SH-48SH35UH-40UH28EH-38EH |

|---|---|

| Means of Transport: | Ocean, Air |

| Application: | Motor Magnet |

| Shape: | Others |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Brand Name: | future-MG |

| Sintered NdFeB Arc magnets: | NdFeB Arc magnets |

| Production Capacity: | 1000000pcs/M |

| Packing: | Cartons vacuum |

| Delivery Date: | 30-60days |

Product Description

The NdFeB material has more advanced properties and multi-polar magnetization, which can make the same size motor generates larger torque or the same powder motor owns more ingenious volume.

So it meets the development demands of the " small, light and thin design" of the motor industry. with these properties, the NdFeB magnets are widely being used in modern advanced industry and high-technology products.

The NdFeb is being widely used in aviation, spaceflight, electron, mechanism, meter and medical treatment field, etc.

So it meets the development demands of the " small, light and thin design" of the motor industry. with these properties, the NdFeB magnets are widely being used in modern advanced industry and high-technology products.

The NdFeb is being widely used in aviation, spaceflight, electron, mechanism, meter and medical treatment field, etc.

Physical and mechanical properties

Comparison of physical properties of sintered neodymium and Sm-Co magnets | ||

Property | Neodymium | Sm-Co |

Remanence (T) | 1–1.3 | 0.82–1.16 |

Coercivity (MA/m) | 0.875–1.99 | 0.493–1.59 |

Permeability | 1.05 | 1.05 |

Temperature coefficient of remanence (%/K) | –0.12 | –0.03 |

Temperature coefficient of coercivity (%/K) | –0.55..–0.65 | –0.15..–0.30 |

Curie temperature (°C) | 320 | 800 |

Density (g/cm3) | 7.3–7.5 | 8.2–8.4 |

CTE, magnetizing direction (1/K) | 5.2×10–6 | 5.2×10–6 |

CTE, normal to magnetizing direction (1/K) | –0.8×10–6 | 11×10–6 |

Flexural strength (N/mm2) | 250 | 150 |

Compressive strength (N/mm2) | 1100 | 800 |

Tensile strength (N/mm2) | 75 | 35 |

Vickers hardness (HV) | 550–650 | 500–550 |

Electrical resistivity (Ω·cm) | (110–170)×10–6 | 86×10–6 |

Our main products are:

1,Metal injection molding, made from the stainless steel, tungsten, Iron-base alloy, tool steel, hard metal alloy.

2,Rare earth magnet, including sintered Neodymium-Iron-Boron, bonded Neodymium-Iron-Boron, sintered Samarium-Cobalt. All magnets are supplied in a wide range of shapes such as: rectangular blocks, discs, rings and segments.

3,Ferrite magnet: Hard ferrite magnet and soft ferrite magnet including the MnZn and NiZn.

4,Die-cast component, made from zinc, aluminum, magnesium alloys.

1,Metal injection molding, made from the stainless steel, tungsten, Iron-base alloy, tool steel, hard metal alloy.

2,Rare earth magnet, including sintered Neodymium-Iron-Boron, bonded Neodymium-Iron-Boron, sintered Samarium-Cobalt. All magnets are supplied in a wide range of shapes such as: rectangular blocks, discs, rings and segments.

3,Ferrite magnet: Hard ferrite magnet and soft ferrite magnet including the MnZn and NiZn.

4,Die-cast component, made from zinc, aluminum, magnesium alloys.