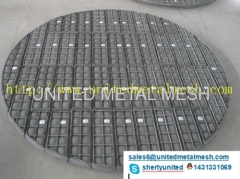

Demister Pad

| Place of Origin: | Hebei |

|---|

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Demister Pad |

Product Description

Features

- Simple structure, lightweight.

- High porosity, less pressure drops.

- Big surfaces area, high demisting efficiency.

- Easy installation, operation and maintenance.

- Long service life.

Selected wire mesh form

| Wire size (mm) | Wire width tolerance (mm) | Bulk density (kg/m3) | Specific surface area (m2/m3) | Porosity | ||

| Flat wire | Round wire diameter | +10 -0 | 182 | 626 | 484 | 0.977 |

| 0.1*0.3 | 0.19 | |||||

| Note: Every 100mm thick mat have 32 layers wiremesh | ||||||

The high-penetration type wire mesh

| Wire size (mm) | Wire width tolerance (mm) | Bulk density (kg/m3) | Specific surface area (m2/m3) | Porosity | ||

| Flat wire | Round wire diameter | +10 -0 | 98 | 313 | 217 | 0.9875 |

| 0.1*0.4 | 0.23 | |||||

| Note: Every 100mm thick mat have 20 layers wiremesh | ||||||

The shock absorber type

| Type | Specification | Filaments specifications (mm) |

| Shock absorber type | 33-30 type | Φ0.08 |

| 38-40 type | Φ0.08 | |

| 20-40 type | Φ0.22 | |

| 30-40 type | Φ0.10Φ0.12 | |

| 30-50 type | Φ0.16 | |

| 40-60 type | Φ0.12 | |

| 30-80 type | Φ0.22 | |

| 50-120 type | Φ0.22 | |

| 40-120 type | Φ0.22 |

● HG5-1404 (1405,1406) -81

The standards are divided into the riser-type(1404), the necking (1405) and full bore type (1406). The diameter of demisteris from 300mm to 6400mm and height is 100mm and 150mm. When ordering need tooffer a figure number and use of the material.

● HG/T21618-1998

New standards merged riser type, reducing neckingtype and full bore type installation form; proposed SP, HP, DP and HR four kindsof network types and expanded the types of material selection; and increased theset specifications size interval density.

| DP | HR/HP | |

| The standard wire specification:0.1+0.03*0.4 | The standard wire specification:0.1+0.02*0.3 | The standard wire specification: φ0.23(φ0.275)\0.1+0.03*0.4mm |

Mark example: HG/T21618 wire mesh demister S1600-100 SP 304/304 it indicatesthat the gratings and wire mesh are made of 304 stainless steel, coat type,diameter 1600mm, height 100mm, SP screen demister grid.

● HG/T21586-98(drawer mesh demister device)

This standard is principally applied to thedemister element often needs to be cleaned or replaced occasions, for examplesulfuric acid drying tower and absorber device. Its selection of nominaldiameter has 56 kinds ranging from DN300mm ~ DN5000mm. When ordering simply needto provide a figure number and choice of materials (316L, NS-80 and RS-2 wiremesh material is commonly used in sulfuric acid plant).

Mark example: HG/T21586.11-98 WME-1600-100 NS-80/Q235-A it means that thewire mesh using the NS-80, grill carbon steel diameter 1600mm, height 100mmdrawer demister pad.

● Other non-standard wire mesh demister

Wavelike type, embedded type, external loading type, SWD1 type, square,rectangular and irregular, and so on.

1, Mesh Block Installation

Mesh block structures of demister pad havetwo types: disk-shaped mesh block and bar mesh block.

It has upload typeand download type two structures. When the location of the manhole opened in theabove of the wire demister, or unmanned hole but equipment flange, choose theupload type wire demister; the manhole location opened in the below of it, thenchoose the download type wire mesh demister.

2, Demister Schematic

After using for some time because of the gas containing particles (such assublimated sulfur, etc.), the wire mesh is partially clogged and prone toflooding, the pressure drop also increased, therefore, the demister pad needsfor proper maintenance.

During the stop of a long time, air will enter thetower body, the moisture in the air and mesh acid are easily formed sweet sour,since the metal mesh generally are intolerant to dilute acid, therefore, itneeds to seize the opportunity to maintain the demister.

The way ofmaintenance is to clean with water, but remember: to avoid the dilute acid onthe demister wire mesh to affect service life, after flushing the demister pad,mesh block must be drying (in the natural state, also can in the sun). Put itinside the tower before the equipment works. Choose to use a constant efficiencyor the innovative adjustable mist eliminator in the production and smeltingenterprises.

.jpg)

.jpg)