API 7-1 Standard Drill Collar

200.0~500.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 3000 pcs/month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler, Service |

| Main Products: | PDC BITS , ROCK BITS, TROCONE BITS, DRAG BITS |

Product Detail

| Means of Transport: | DHL UPS Fedex EMS, Ocean, Air, Land |

|---|---|

| Processing Types: | Metal |

| Processing: | Drilling Machine |

| Automatic Grade: | Semiautomatic |

| Workpiece and Weight: | Heavy-duty Machine Tool |

| Precision: | Precision |

| Controlling Mode: | CNC |

| Usage: | Special |

| Brand Name: | ZK |

| Production Capacity: | 3000 pcs/month |

| Packing: | wooden box or steel box or as required |

| Delivery Date: | within 15~30 days |

Product Description

product name API 7-1 Standard Drill Collar

Drill Collars are manufactured from the AISI 4145H Modified alloy steel bars. Fully heat-treated to meet API 7-1.

Drill Collars are manufactured from the AISI 4145H Modified alloy steel bars. Fully heat-treated to meet API 7-1.

Standard Drill Collar Features & Options

API pin stress relief groove and box boreback

An API pin stress relief can be used on all drill collars and downhole tools. It is a recommended option in situations where fatigue can occur as a result of bending. By removing any unengaged threads in the high stress areas of the drill collar connection, it is less likely to crack due to fatigue because the bending will take place in the area of the connection with smooth surfaces that are free of stress concentrations.

An API pin stress relief can be used on all drill collars and downhole tools. It is a recommended option in situations where fatigue can occur as a result of bending. By removing any unengaged threads in the high stress areas of the drill collar connection, it is less likely to crack due to fatigue because the bending will take place in the area of the connection with smooth surfaces that are free of stress concentrations.

Phosphate coatingAll threaded connections can be treated with a phosphate coating to help prevent threads from galling.

SpiralingThree optional spiral grooves can be placed on the outer diameter of the collar to allow the mud to circulate freely around the drill collar. This is to equalize the pressure as well as to prevent a seal forming. This will help reduce any chances of differential sticking.

HardbandingOptional hardbanding is available in various materials. Drill collar hardbanding is normally applied flush to the outside diameter of the bar. Other configurations are available upon request.

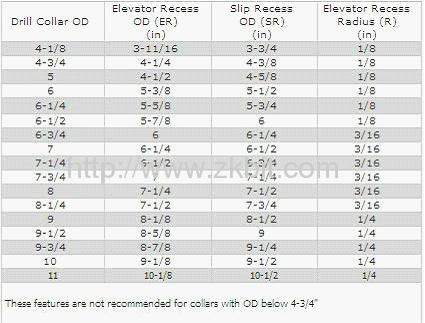

Elevator and slip recessesOptional slip and elevator recesses are available to improve handling and safety. These two features can be used together or separately. These options are cut as per API recommended practice 7G.

API 7-1 Standard Drill Collar