Thin Wall Welded Pipe

| Min. Order: | 5 Ton |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 300000Tons per year |

| Place of Origin: | Hebei |

Company Profile

| Location: | Langfang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Cold Rolled Steel Pipe, Welded Steel Pipe, Round Pipe, Square Pipe, Rectangular Pipe |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Technique: | Welded |

| Brand Name: | Huamao |

| Specification: | Round, Square, Rectangular, Window Section, Shaped Pipe |

| Grade: | Carbon Steel |

| Outer Diameter: | 0.3150 Inch to 3.9370 Inch |

| Thickness: | 0.4MM to 2.0MM |

| Length: | 10.5Meters Max. |

| Usage: | Furniture Industry, Salvage Industry, Tourism Industry, Fitness Apparatus Industry and Municipal Construction Projects |

| Steel Grade: | Q195 and Q235 |

| Executive Standard: | ASTM, DIN, JIS, GB |

| Factory History: | 14 Years |

| Quanlity Controlling: | Department in charge |

| Customer Service: | Professionally |

| We Are Good at: | Quality |

| Tested Percentage prior to shipment: | 100% |

| Work Shop Area: | 50000 Square Meters |

| Present Market: | US, Belgium, U.K, Germany, Ethiopia, Mauritius and Brazil etc |

| Agent: | Requested |

| Production Capacity: | 300000Tons per year |

| Packing: | Export Packing suitable for Containers Load or Bulk cargo shipping |

| Delivery Date: | 30 day |

Product Description

Our factory have 14years experience to produce the thin wall pipe. The thin wall pipe is afraid of rusty if the pipe need to be storage for long time. We put pure oil on pipe after welded process to prevent rusty.

Thin Wall Welded Round Pipe

Thin Wall Welded Round Pipe

Executive Standard: ASTM, DIN, JIS, GB

Grade: Q195-Q235

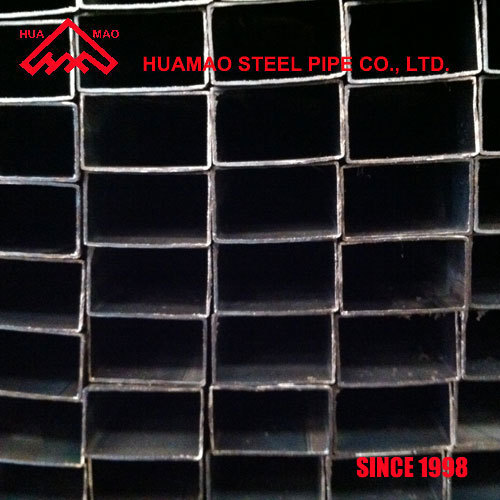

Thin Wall Welded Square Pipe

Executive Standard: ASTM, DIN, JIS, GB

Grade: Q195-Q235

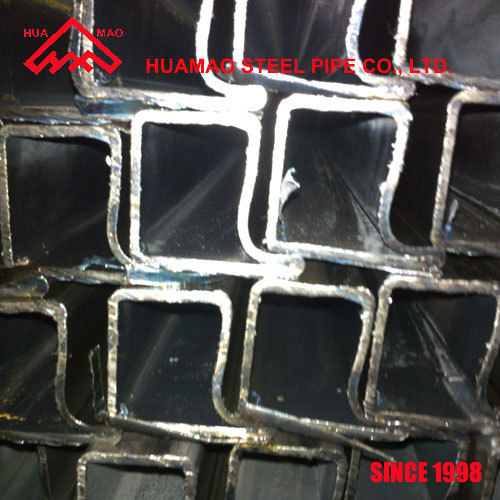

Thin Wall Welded Rectangler Pipe

Executive Standard: ASTM, DIN, JIS, GB

Grade: Q195-Q235

Grade: Q195-Q235

| Product | Outside Diameter | Thickness | ||

| Inches | MM | Inches | MM | |

| Black annealed pipes | 0.3150-3.9370 | 10-100 | 0.0118-0.0787 | 0.3-2.0 |

| Bright pipes | 0.3150-3.9370 | 10-100 | 0.0118-0.0787 | 0.3-2.0 |

| Pre-galvanlized pipes | 0.3150-3.9370 | 10-100 | 0.0118-0.0787 | 0.3-2.0 |

| Cold hard pipes | 0.3150-3.9370 | 10-100 | 0.0118-0.0787 | 0.3-2.0 |

Thin Wall Welded Square Pipe

Executive Standard: ASTM, DIN, JIS, GB

Grade: Q195-Q235

| Product | Outside Diameter | Thickness | ||

| Inches | MM | Inches | MM | |

| Black annealed pipes | 0.3937²-2.3622² | 10²-60² | 0.0118-0.0787 | 0.3-2.0 |

| Bright pipes | 0.3937²-2.3622² | 10²-60² | 0.0118-0.0787 | 0.3-2.0 |

| Pre-galvanlized pipes | 0.3937²-2.3622² | 10²-60² | 0.0118-0.0787 | 0.3-2.0 |

| Cold hard pipes | 0.3937²-2.3622² | 10²-60² | 0.0118-0.0787 | 0.3-2.0 |

Thin Wall Welded Rectangler Pipe

Executive Standard: ASTM, DIN, JIS, GB

Grade: Q195-Q235

| Product | Outside Diameter | Thickness | ||

| Inches | MM | Inches | MM | |

| Black annealed pipes | 0.2362*0.3937-1.9685*3.9370 | 6*10-50*100 | 0.0118-0.0787 | 0.3-2.0 |

| Bright pipes | 0.2362*0.3937-1.9685*3.9370 | 6*10-50*100 | 0.0118-0.0787 | 0.3-2.0 |

| Pre-galvanlized pipes | 0.2362*0.3937-1.9685*3.9370 | 6*10-50*100 | 0.0118-0.0787 | 0.3-2.0 |

| Cold hard pipes | 0.2362*0.3937-1.9685*3.9370 | 6*10-50*100 | 0.0118-0.0787 | 0.3-2.0 |

Thin Wall Welded Window Section

Executive Standard: ASTM, DIN, JIS, GB

Grade: Q195-Q235

| Product | Outside Diameter | Thickness | ||

| Inches | MM | Inches | MM | |

| Black annealed pipes | T/Z/L 0.9843-1.4960 | T/Z/L 25-38 | 0.0236-0.0787 | 0.6-2.0 |

| Bright pipes | T/Z/L 0.9843-1.4960 | T/Z/L 25-38 | 0.0236-0.0787 | 0.6-2.0 |

| Pre-galvanlized pipes | T/Z/L 0.9843-1.4960 | T/Z/L 25-38 | 0.0236-0.0787 | 0.6-2.0 |

| Cold hard pipes | T/Z/L 0.9843-1.4960 | T/Z/L 25-38 | 0.0236-0.0787 | 0.6-2.0 |

PACKING:

If you are interested in this product or just want to know more about steel pipes, never hesitate to contact us. We are looking forward to developing business relationships with you.

Straight Welding in producing pipe is straight type of ERW. ERW stands for Electric Resistance welded pipe. A plate rolled to become a pipe and welded using Electric Resistance Welding process.

The carbon steel whose properties are determined primarily by the amount of carbon present. Apart from iron and carbon, manganese up to 1.5% may be present as well as residual amounts of alloying elements such as nickel, chromium, molybdenum, etc. It is when one or more alloying elements are added in sufficient amount that it is classed as an alloy steel.