CNC Fiber Laser Cutting for Metal 3015 Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Hydraulic Press, Shearing Machine, Sheet Metal Press Brake, Hydraulic Pre-bending CNC Plate Rolling Machine |

Product Detail

| Model No.: | KJG-150300JH |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Accurl |

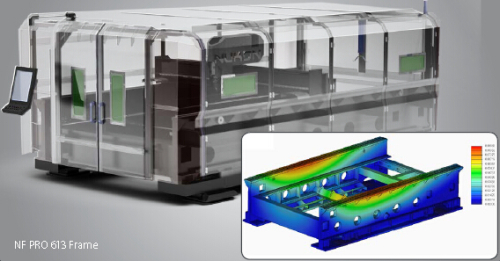

| Laser type: | IPG fiber laser generator from USA |

| Laser wavelength: | 1070nm |

| Laser power output rating: | 2000W |

| X-axis travel: | 1500mm |

| Y-axis travel: | 3000mm |

| Working table: | Open design, fixed table |

| Driving mode: | Double rack and pinion driving system |

| Format supported: | PLT, DXF, AI etc |

| Position accuracy: | 0.05mm |

| Total Power consumption: | 30KW |

| Production Capacity: | 30 |

| Packing: | Steel Pallet for Laser Cutting Machine |

| Delivery Date: | 30 |

Product Description

CNC Fiber Laser Cutting for Metal 3015 Machine

Product Application

The Accurl@ Fiber Lasers bring you a cost effective, low-maintenance, low operating cost,environmentally friendly solution to your organization. We deliver a machine that providesquality cutting and tolerances with small productivity loss between jobs, equating to higher returnon investments. Our fiber laser cutting machines are developed and sold based on these criteria.

• Manufactured by people who use their own machines.

• The resonator comes with a 100,000 hour warranty from the manufacturer (IPG)

• Higher cutting speeds possible

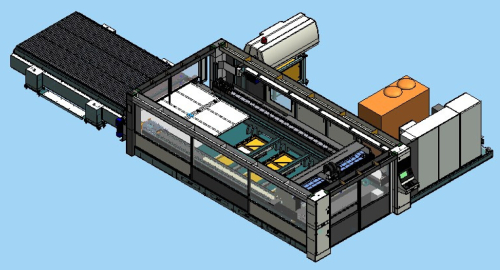

• Dual interchangeable tables allow for faster loading and unloading, reducing downtime

• Laser wavelength is one-tenth of a CO2 laser

• Reduction in cutting variables or tribal knowledge

• Fiber Laser is extremely efficient, equates to very low power consumption

• Low cost of operation, energy cost reduced, no laser gases requied to produce beam

• High cutting flexibility (Steel, Stainless Steel, Brass, Copper, Titanium, Aluminum, and more)

• Laser beam transmitted through a fiber optic.cable rather than with mirrors and channel tubing resulting in negligible power loss.

• Created and tested in a 100,000 sq ft Research and Development facility operating 9 metal cutting fiber Lasers, cutting 24/7.

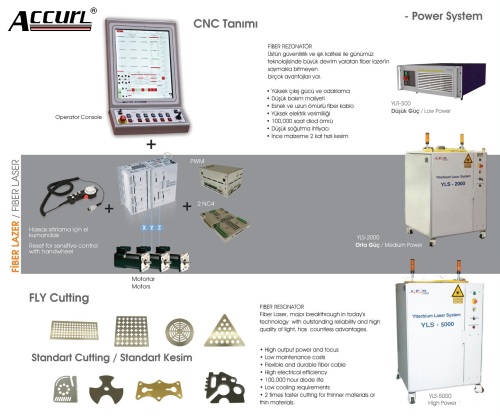

Main Features

•The ACCURL@ Fiber Lasers bring a cost eᴀective, low-maintenance, low operating cost and environ-mentally friendly solution to your organization. Our ἀber laser machines provide quality cutting and tolerances with minimal productivity loss between jobs, equating to a higher re turn on investment.

• Acceleration speed: 19,6 m/s2 (2G).

• Maximum simultaneous positioning speed: 160m/min.

• Precision: + - 0.05 mm.

• Energy efficiency: greatly reduced power consumption.

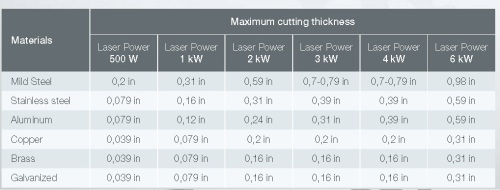

• Excellent cutting quality for fine thic kness and medium thickness sheet metals.

• IPG Resonator. Power output from 1 kw to 6 kw .

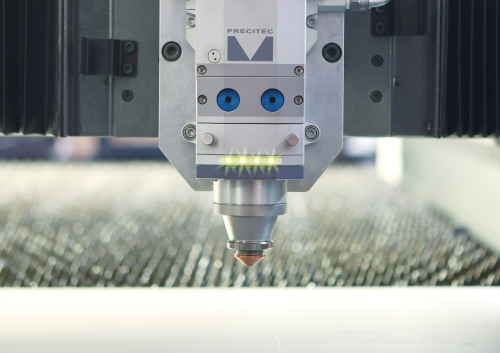

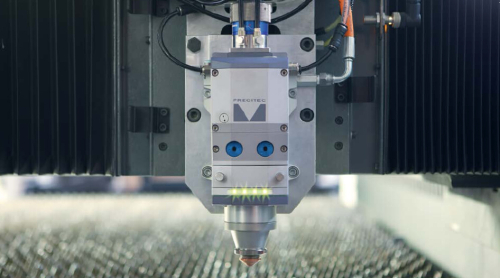

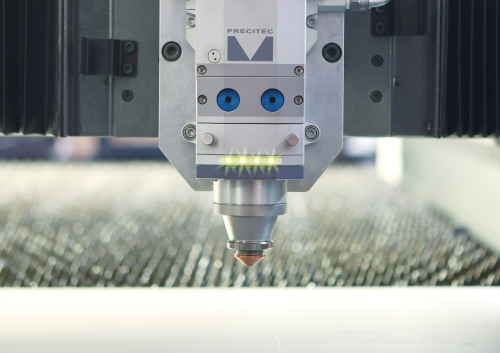

• Precitec light cutter cutting head with po wer output up to 2kw.

• Precitec HP cutting head for po wer output of more than 2kw.

• Fully enclosed and cabinned to ensur e máximum operator protection.

• Effective high to low pressure gas exchange system.

• Capacitative Sensor, high pressure cutting head.

• TCI Cutting parameter tables.

• Pre-cut film protector.

• Automatic mechanized Nesting power output control function (edges, start-ups).

• Automatic time and unit cost calculation function.

• Network connection from external.

• Automatic table exchanger (included in series models).

• Smoke extraction (included in series models).

• 3 point reference sensor (sheet metal rotation detector).

• Piercing Sensor.

• Collection of work pieces and trimmings.

• Dual proportional valve control system for different gas pressures and special system for high pressure cutting.

| Fiber Laser Metal Cutting Machine Technical Parameters | |||

| Model No. | KJG-150300JH | KJG-150300JH | XJGC-150300JH |

| Laser Type | IPG / Coherent / Raycus | ||

| Laser Power | 1000W | 2000W | 3000W |

| Cutting Area | 1500mmX3000mm | ||

| Working Table Structure | Fixed working table | Pallet Changer | |

| Control System | PMAC full-closed loop servo control | ||

| Positioning Accuracy | ±0.04mm | ||

| Driving Mode | Double gear rack driving | ||

| Idle/Processing Speed | 72m/min / 36m/min | 100m/min / 30m/min | |

| Laser Head | Precitec / Golden Laser / Laser Mech | ||

| Cooling System | Dual temperature dual control water chiller | ||

| Protection System | Open Type | Enclosure protection | |

| Format Supported | PLT, DXF, BMP, AI, DST, DWG, etc. | ||

| Power Supply | 380V / 220V | ||

| Total Power | 7KW / 11KW | 17KW / 8~22KW | |

| Floor Space | 5.6m x 3.2m | 9m X 4m | |

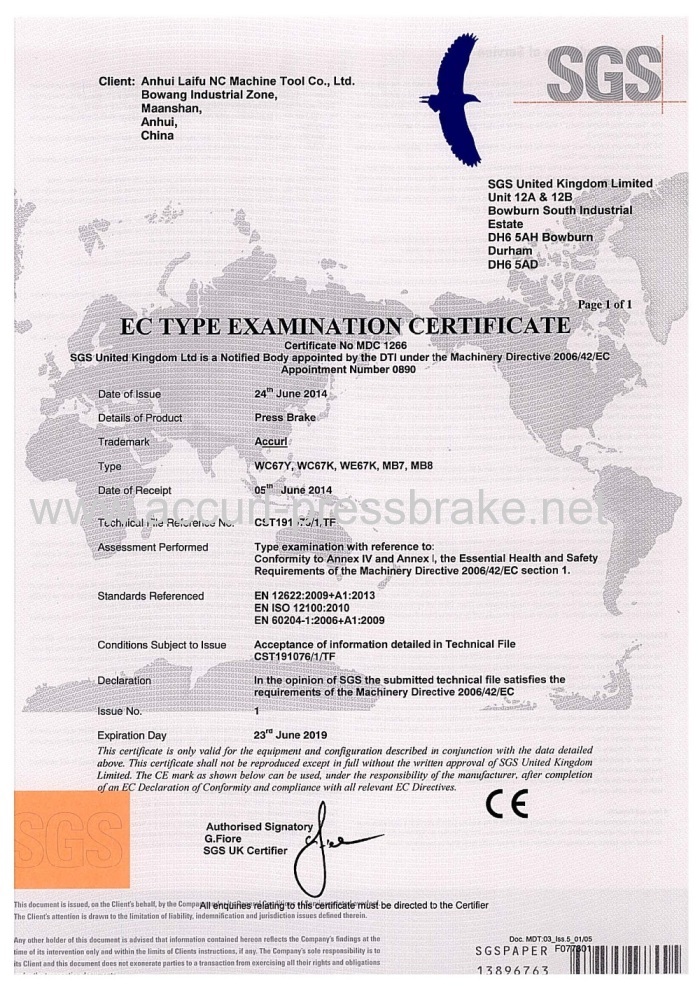

Certifications

Detailed Images

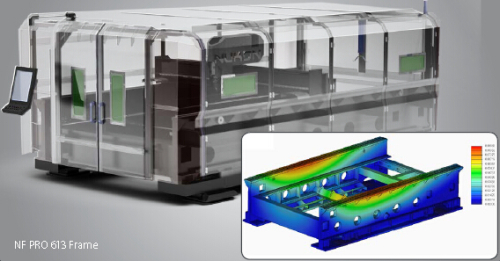

Machine Body

the steady gantry framework provides an open worktable

Synchronous X/Y/Z axes: The Z-axis can run 150mm, suitable for cutting many varieties of metal sheets.

High quality guarantees its durability and easier maintenance.

Accurl has 4 servo motors for all axial movements.These are the latest technology single cable servomotors.

Power and process data are transmitted in onestandard motor cable, significantly reducing costs.

This technology also gives more accurate positioningand more geometrically accurate parts.

Conveyor System

A special hard steel construction conveyor system, standard on our machines, is located under the workspace. The conveyor removes slag and small parts during the cutting process. The operator can choose the movement direction of the conveyor.

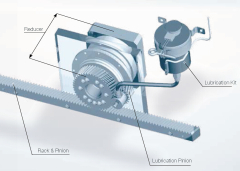

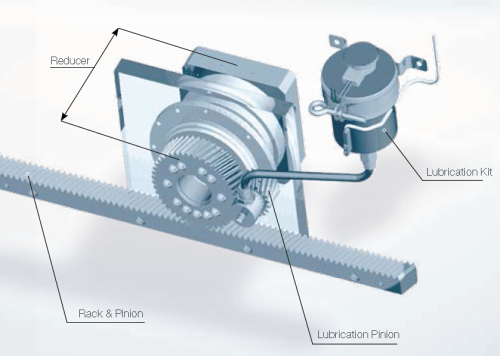

High Precision Drive System

The Wittenstein high precision helical gear rack and pinion system uses precision planetary and servo-worm reducers.

Our special design eliminates any noticeable backlash variance. The rack used in these systems is also hardened & precision ground.

Single Cable Servo Motor Technology

Standard Euipment

NOZZLE CLEANER

Keeping your machine cutting quickly and cleanly is important. Our nozzle cleaner helps improve the life of your nozzles so your cuts stay consistent, longer.