pre-bending plate 4-roller bending machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 15sets/25days |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Hydraulic Press, Shearing Machine, Sheet Metal Press Brake, Hydraulic Pre-bending CNC Plate Rolling Machine |

Product Detail

| Model No.: | W12-50*3000 |

|---|---|

| Means of Transport: | Ocean |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Roll Forming Machine |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | ACCURL |

| Max.rolling thickness: | 50mm |

| Max. rolling width: | 3000mm |

| Rolling speed: | 4.5m/min |

| Loaded with minimum diameter: | 1500mm |

| Roll diameter: | 500mm |

| Main motor: | 55kw |

| Dimension: | 9000*4000*3300mm |

| Production Capacity: | 15sets/25days |

| Packing: | standard exporting package |

| Delivery Date: | 30 days |

Product Description

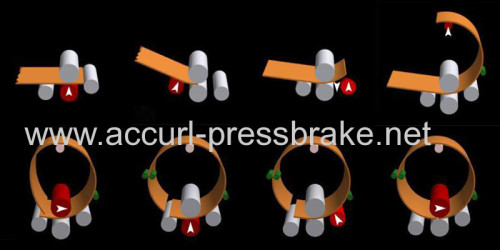

pre-bending plate 4-roller bending machine

1. Accurl machine has specialized in metal plate rolling machine for 17 years.

Our new factory covers a total area of 46,600 square meters.

Our machine export to more than 200 conties all over the world.

We professional R&D team, and we have World-class design and manufacturing capabilities.

Accurl machines are with CE,ISO,SGS certificates.

|

2.W12 series hydraulic 4-roller rolling machine

The Feature of 4 Roller Rolling Machine : |

■Totally European design,streamlined looking,frames of our machines are fabricated, welded steel (ST-52). Roll shafts, materials and bearings used in production are European quality. latest hydraulic technology CNC programmable dual pre pinch.

■ The machine widely used in petroleum, chemical industry, cement, boiler, shipbuilding, aviation, water conservancy, power transmission towers …. Its working principle is rotating bending deformation. Safety devices in compliance with European regulation. CE mark.

The whole structure of machine : |

■ The main structure of the equipment includes upper roller, lower roller and movement mechanism, supporting mechanism,main drive mechanism, downturn system, left and right machine frame, chassis and balance mechanism, hydraulic and electrical control systems.

■ It allows for excellent roundness, thanks to the Planetary movement of the side rolls (Accurl patent), moving them to the center of the machine (the tightest geometry available), compared to the inclined linear guides of other brands that, especially on large diameters, move farther away from the central roll and the plate clamping.clamping pressure is adjustable(no-existent skidding,productivity is 80% than three roller plate rolling machine).

■ Hydraulic pressure adjustment system to control rolls deflection under load. Greasing free with sealed bearings and Permanent lubrication technology(bearing life period without refueling).

The Feature of machine : |

■ Fully hydraulic operated plate rolling machine with pre pinch roll forming of the plate edges. Rollers driven with direct coupling hydraulic motorized protected against overloading.

■ Upper roller likes drum with collaboration of carrier roller permit continual bending of any thickness of plate. Hardening of the 4 rolls high resistance surface with induction treatment.Operation control unit with centralised electric console movable on wheels around the machine

■ Safe work, fixed two down roller, upper roller does horizontal and vertical movement, and the plate don't move during upper roller moving.

■ Pre-bending facility with pinch pressure adjustable to compensate for rolls deflection under load upon plate thickness.

■ Conical bending attachment hydraulic operated to form cones- fast and easy procedure.Opening drop-end with self align bearings.

■ Hydraulic power from centralized unit self enclosed with multiple pumps for simultaneous bending operations.

Control system of machine: |

■ CNC controller 4 axis programmable for automatic plate rolling with digital display of the rolls position and teach-in input of parameters.

■ It is controlled, in entry-level, by a user-friendly CNC, to roll parts in automatic mode. More powerful CNC (the most advanced in the industry, until those selected by NASA), are self-programmable, without the need of experienced operators.

■ HMI (human machine interface), intelligent operation. Self-compensating, single operate, high efficiency, safe and convenient.

■Centralized console with electric commands easy one-man operation.machine fully hydraulic operated with cylinders and pumps

Design of the rolled plate on the screen of the CNC with direct input of plate parameters.

Configuration of Hydraulic Plate Rolling machine is follows: |

■ Motor: Siemens

■ Electronic elements: Schneider

■ Axletree: Double-row self-aligning bearing from Germany

■ PLC: OMRON from Japan

■ Hydraulic valve: Bosch

■ Gear pump: Yuken

■ Digital display system: Touch Screen for Delta

■ Automatic lubrication system:Sino-Japanese joint,which has block alarm

3. Specification of Hydraulic Plate Rolling machine is follows: |

Type | Max. rolling thickness (mm) | Max. rolling width (mm) | Rolling speed (m/min) | Pre-curved thickness (mm) | Upper roll diameter (mm) | Down roll diameter(mm) | Side-roll | Dimension (mm) | Motor (Kw) |

W12-12×2000 | 12 | 2000 | 5.45 | 10 | 260 | 260 | 200 | 5600*2000*2070 | 18.5 |

W12-12×2500 | 12 | 2500 | 5.5 | 10 | 300 | 300 | 220 | 6300*2000*1200 | 18.5 |

W12-12×4000 | 12 | 4000 | 4 | 10 | 410 | 360 | 280 | 7600*2000*1800 | 30 |

W12-16×2000 | 16 | 2000 | 5.5 | 12 | 300 | 300 | 220 | 5800*2000*1800 | 18.5 |

W12-16×2500 | 16 | 2500 | 6.5 | 12 | 330 | 330 | 260 | 6810*2000*1870 | 22 |

W12-20×2000 | 20 | 2000 | 6.5 | 16 | 330 | 330 | 260 | 6000*2000*1850 | 22 |

W12-20×2500 | 20 | 2500 | 6.5 | 16 | 360 | 360 | 280 | 6850*2000*2070 | 30 |

W12-20×3000 | 20 | 3000 | 4.5 | 16 | 410 | 400 | 320 | 730*2100*2200 | 37 |

W12-25×2000 | 25 | 2000 | 6.5 | 22 | 360 | 360 | 280 | 6300*2300*2070 | 30 |

W12-25×2500 | 25 | 2500 | 5 | 22 | 410 | 400 | 320 | 8000*2600*2100 | 37 |

W12-25×3000 | 25 | 3000 | 5 | 22 | 480 | 480 | 400 | 9000*3200*2500 | 37 |

W12-25×4000 | 25 | 4000 | 4 | 22 | 560 | 520 | 420 | 10100*3500*2900 | 45 |

W12-30×2000 | 30 | 2000 | 5 | 25 | 410 | 400 | 320 | 7500*2600*2500 | 37 |

W12-30×2500 | 30 | 2500 | 4.5 | 25 | 480 | 480 | 400 | 8400*2590*2600 | 37 |

W12--30×3000 | 30 | 3000 | 4 | 25 | 560 | 520 | 420 | 9200*3500*2900 | 45 |

W12--30×4000 | 30 | 4000 | 4 | 25 | 650 | 580 | 480 | 10200*3500*2900 | 55 |

W12-40×2000 | 40 | 2000 | 4.5 | 36 | 480 | 480 | 400 | 8200*3000*2500 | 37 |

W12-40×2500 | 40 | 2500 | 4 | 36 | 560 | 520 | 420 | 8700*3500*2900 | 45 |

W12-40×3000 | 40 | 3000 | 4 | 36 | 650 | 580 | 480 | 9200*3600*3000 | 55 |

W12-80×3200 | 80 | 3200 | 3 | 70 | 800 | 780 | 620 | 13500*3500*3800 | 75 |

W12-90×4000 | 90 | 4000 | 3 | 80 | 900 | 880 | 700 | 15000*3800*4200 | 90 |