Inconel625 set screw bolt nut washer uns n06625 DIN913

| Min. Order: | 200 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000pcs |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Nanjing, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Washer, Fastener, Bolt, Nut, Thread Rod |

Product Detail

| Model No.: | DIN GB ASME JIS |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Others |

| Material: | Others |

| Brand Name: | xdo |

| Diameter: | M3 to M100 |

| Length: | 10mm to 3000mm |

| Capacity: | according to size and length |

| Material: | Inconel625 |

| Other name: | GH3625 |

| GH625: | 2.4856 |

| w.nr2.4856: | NA21 |

| NiCr22Mo9Nb: | NS336 |

| Production Capacity: | 10000pcs |

| Packing: | carton box,pallet, wooden box |

| Delivery Date: | at least 3 days |

Product Description

Material :

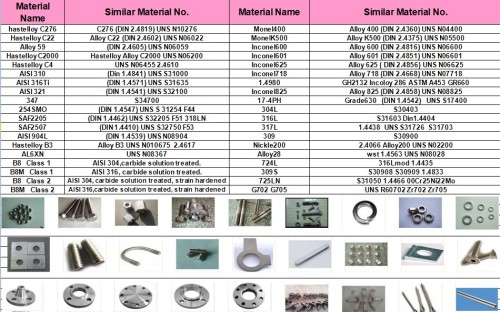

304 304L 347 316 316L 1.4404 316Ti 1.4571 S31635 317L 1.4438 254SMO 1.4547 UNS S31254 F44 654SMO 1.4652 S32654 AL6XN UNS N08367 310S 1.4841 309S 2205 S31803 F51 A182 1.4462 2507 S327501.4410 F53 321 1.4541 S32760 Monel400 UNS N044002.4360 Alloy400 Monelk500 AlloyK500 UNS N05500 2.4375 Alloy59 UNS N06059 2.4605 Inconel718 UNS N07718 2.4668 GH169 GH4169 724L 725LN 309S 1.4833 Hastelloy C276 UNS N10276 2.4819 NS333 2.4602 UNS N06022 Hastelloy B2 C22 Hastelloy C4 UNS N06455 2.4610 GH2132 A286 316Ti Inconel625 Alloy59 Inconel600 Inconel925 Inconel825 UNS N08825 Alloy825 2.4858 GH3030 Alloy20 SUS347 17-4PH Alloy800

Standards: GB ,ANSI/AMSE, DIN, JIS and BS,UNI etc

In stock items: 310S Hex nuts M6 - M20 AL6XN hex nut M6 904L Hex nuts M6 to M20, SAF2205 Hex nuts M6 to M20

Thanks for your time to check our webste, here we list some materials which used to manufacture different standard fasteners. Our factory and packing pictures. If you have any more want to know,

Kindly contact me ,My name is Rachel,

Hope our products could do you a favor. Enjoy everyday!

Product Material description: From M5 to M100 from 1/4"X 4", we all could manufacture.Standard or Non standard

Hex bolt, Hex nut ,washer, thread rod ,flange, screw,

ASMEB18.2.1,ASMEB18.2.2, ASME B18.22.1, DIN933, DIN931, GBstandard, JIS, BS, and so on.

Factory production looking:

A circle though small ,is yet complete ! On every step production, we have staff to supervise ,only when this step done well,then we move to next step. For finished products, we test every 60pcs per 100pcs., Although this practice cost much time and energy, but it is worthy.

1.Strictly according to ISO9001 System

2.10 years experience on fastener production

3.Well control on procedure and quality control

4.Pay much attention on client`s feedback

5.Mill test certificate always provided according to finished products

6.Most raw material are from Japan ,America,Europe and China biggest steel plant

7.Good and Relaxed working enviroment for staff

8.OEM and small quantity such as 50 to 100pcs is accepted

Appliance :

Industries served by Nanjing xidiou stainless steel include – but are not limited to – the following:

· Power generation

· Marine/naval transportation

· Diesel engine

· Food processing

· Power turbine

· Water works

· Piping systems

· General industrial

· Oil & gas industry

· Petrochemical industry

· Pulp & peper industry

· Sea water desalination

· Flue gas desulphuration

· environment industries

Any more details , Contact us ! 0086-15251877296 Rachel will take the phone!

Always improve ! Always put client first !

Our Brand : XDO

Material introduction:

Inconel 625 is a corrosion and oxidation resistant nickel alloy that is used both for its high strength and outstanding aqueous corrosion resistance. Its outstanding strength and toughness is due to the addition of niobium which acts with the molybdenum to stiffen the alloy's matrix. Alloy 625 has excellent fatigue strength and stress-corrosion cracking resistance to chloride ions. This nickel alloy has excellent weldability and is frequently used to weld AL-6XN. This alloy resists a wide range of severely corrosive environments and is especially resistant to pitting and crevice corrosion. Some typical applications Inconel 625 is used in are chemical processing, aerospace and marine engineering, pollution-control equipment, and nuclear reactors

In what applications is Inconel 625 used?

· Aircraft ducting systems

· Aerospace

· Jet engine exhaust systems

· Engine thrust-reverser systems

· Specialized seawater equipment

· Chemical process equipment

Fabrication with Inconel 625

Alloy 625 has excellent forming and welding characteristics. It may be forged or hot worked providing temperature is maintained in the range of about 1800-2150° F. Ideally, to control grain size, finish hot working operations should be performed at the lower end of the temperature range. Because of its good ductility, alloy 625 is also readily formed by cold working. However, the alloy does work-harden rapidly so intermediate annealing treatments may be needed for complex component forming operations. In order to restore the best balance of properties, all hot or cold worked parts should be annealed and rapidly cooled. This nickel alloy can be welded by both manual and automatic welding methods, including gas tungsten arc, gas metal arc, electron beam and resistance welding. It exhibits good restraint welding characteristics.

Chemical Composition, %

Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C |

20.00-30.00 | Remainder | 8.0-10.0 | 1.0 max | 3.15-4.15 | .40 max | .40 max | .10 max |

Fe | Mn | Si | P | S | |||

5.0 max | .50 max | .50 max | .015 max | .015 max |

Mechanical Properties

Representative Tensile Properties, bar, 1800° F anneal

Temp° F | Tensile (psi) | .2% Yield (psi) | Elongation in 2 " (%) |

70 | 144,000 | 84,000 | 44 |

400 | 134,000 | 66,000 | 45 |

600 | 132,000 | 63,000 | 42.5 |

800 | 131,500 | 61,000 | 45 |

1000 | 130,000 | 60,500 | 48 |

1200 | 119,000 | 60,000 | 34 |

1400 | 78,000 | 58,500 | 59 |

1600 | 40,000 | 39,000 | 117 |

Characteristic as below:

1. Excellent corrosion resistance of different kinds of media in both oxidation and reduction environments.

2. Excellent resistance of pitting and crevice corrosion, and won't happen stress corrosion cracking because of chloride.

3.Excellent resistance of the inorganic acid corrosion performance, such as nitric acid, phosphoric acid, sulfuric acid, hydrochloric acid and the mixture of sulfuric acid and hydrochloric acid.

4. Excellent corrosion resistance of different kinds of inorganic acid mixture performance.

5. Good corrosion resistance of a variety of concentrations of hydrochloric acid when the temperature up to 40℃ .

6. Good machining and welding, no weld cracking sensitivity.

7. Have pressure vessel authentication for the wall temperature between -196450℃ .

8. Apply for the highest standard lever VII of acidic environment by the NACE ( MR-01-75)authorized.

Inconel 625 Metallurgical structure

625 is face-centered cubic lattice structure. Dissolve out the carbon granule and instability quaternary phase, then change it to stability Ni3 (Nb,Ti) trimetric lattice around 650℃ after a long time heat preservation. nickel-chromium content will strength the mechanical performance in the state solution while suppress the plasticity.

Inconel 625 Corrosion resistance

625 own a very good corrosion resistance in many media, especially with excellent resistance to pitting, crevice corrosion, intercrystalline corrosion, and erode in oxide, also good resistance to inorganic acid corrosion, such as nitric acid, phosphoric acid, sulfuric acid and hydrochloric acid. 625 can resist the alkali and organic acid corrosion in the oxidation and reduction environment. Effect resists the chloride reduction stress corrosion cracking. Normally no corrosion in the sea-water and industry environments since high corrosion resistance to the sea-water and salting liquid,as well as in high temperature, without sensitivity during welding. 625 have the resistance to oxidation and carbonizing in the static and cycle environments, also hacve the resistance the chlorine corrosion.

Inconel 625 Typical application field as below:

1 .The Organic chemical process parts contains chloride, especially in the use of acid chloride catalyst.

2. The digester and bleacherin the use of paper pulp and paper making industry.

3.Absorption tower, re-heater,gas import board, fan, blender, fair water fin, flue and so on for using in flue gas desulfurization system.

4. The equipment and parts in the use of acidic gas environments.

5. Acetic acid and anhydride reaction generator

6. Sulfur acid cooling